Abstract

Biodegradable polymer materials (known as biocomposites) are widely used for manufacturing of drug delivery technology for controlled and sustained release pattern. The building blocks of plastic materials are polymers, which are constantly being used in an increasing number of applications. Because of this, a lot of researchers are devoting their efforts to creating innovative polymer composites using components that exist naturally as well as changing conventional materials to make them more user-friendly. The utilisation of biopolymers and biofibers as raw materials is done with consideration for the environment. These days, scientists are adding tiny amounts of a novel type of substance called a nanofiller to a variety of biopolymer-based composites. These nanofillers will function as additives, improving the mechanical, thermal, flame-retardant, and water-absorption behaviour of the nano composite materials while preserving their ideal density. An overview of the many biodegradable polymers that are now in use, their characteristics, and recent advancements in their synthesis and uses are provided in the review that follows.

Keywords

biodegradable composites, biofiber, biopolymer, polymer blends, ocular drug delivery.

Introduction

Many scientists are still interested in the development of novel biopolymer materials, which has been going on for a while because synthetic plastics do not break down easily, there is a worldwide drive to develop biodegradable polymers in order to dispose of them. As these materials continue to be developed, industry needs to find innovative applications for them. [1]

Biodegradable polymers are frequently used to lower the amount of waste produced. Biopolymers offer several qualities in addition to being biodegradable, such as air permeability, low temperature seal ability, availability, and affordability. A variety of biopolymers are utilised in packaging, including chitosan, starch, cellulose, PLA, PCL, and PHB. The usage of mixes of various biopolymers, such as starch-PLA and starch-PCL blends, is currently popular in food packaging. [11]

Biodegradable polymer-based nanoparticles have proven to be a valuable tool in the treatment of neurodegenerative diseases due to their high drug-loading capacity and ability to cross the blood-brain barrier. [26] Additionally, their size, shape, and available surface area for biomolecule conjugation make them useful in the diagnosis and treatment of cardiovascular disease. In the event that an unstable active ingredient is present, polymeric nanoparticles can preserve the integrity of drug molecules for more effective distribution because of their capacity for long-term protection. For instance, nitric oxide molecules can be contained in PLGA nanoparticles by employing (trans- [RuCl ([15] ane) (NO)]2+) as a nitric oxide donor; PLGA-poly (ethylene glycol) (PEG) shields curcumin from macrophages; and PEG lessens the toxicity and makes gold nanoparticles more stable.[4][27]

The purpose of this review of the literature is to give information about the developments made in the field of biodegradable polymer materials. We'll look at biodegradability, component materials, uses, biodegradation processes, and the materials' effects on the environment and the economy.

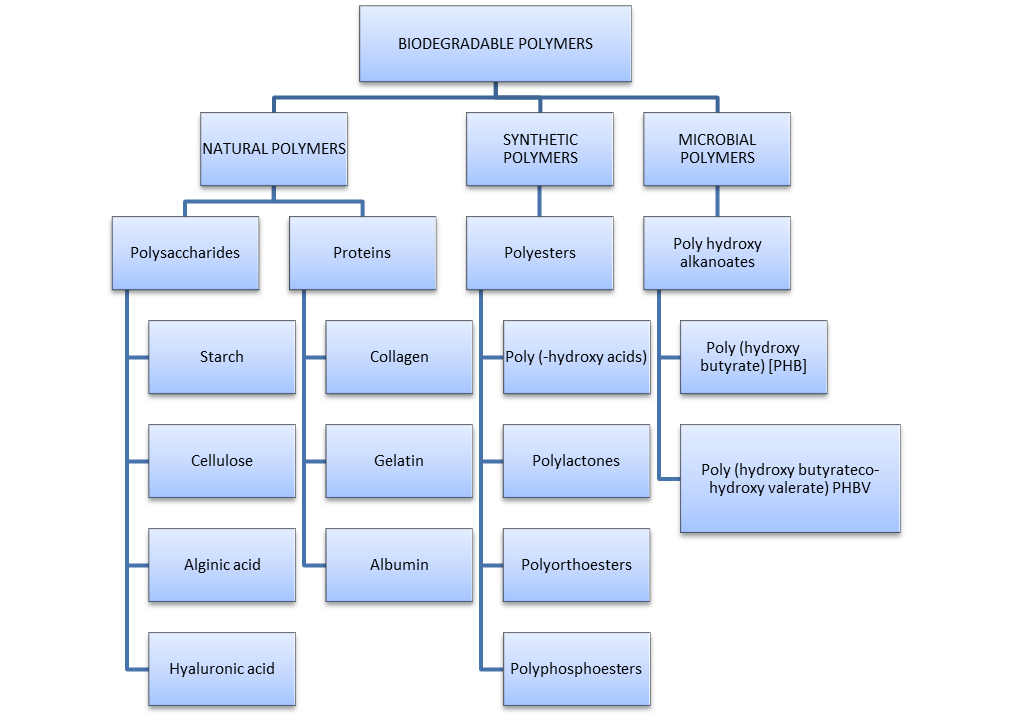

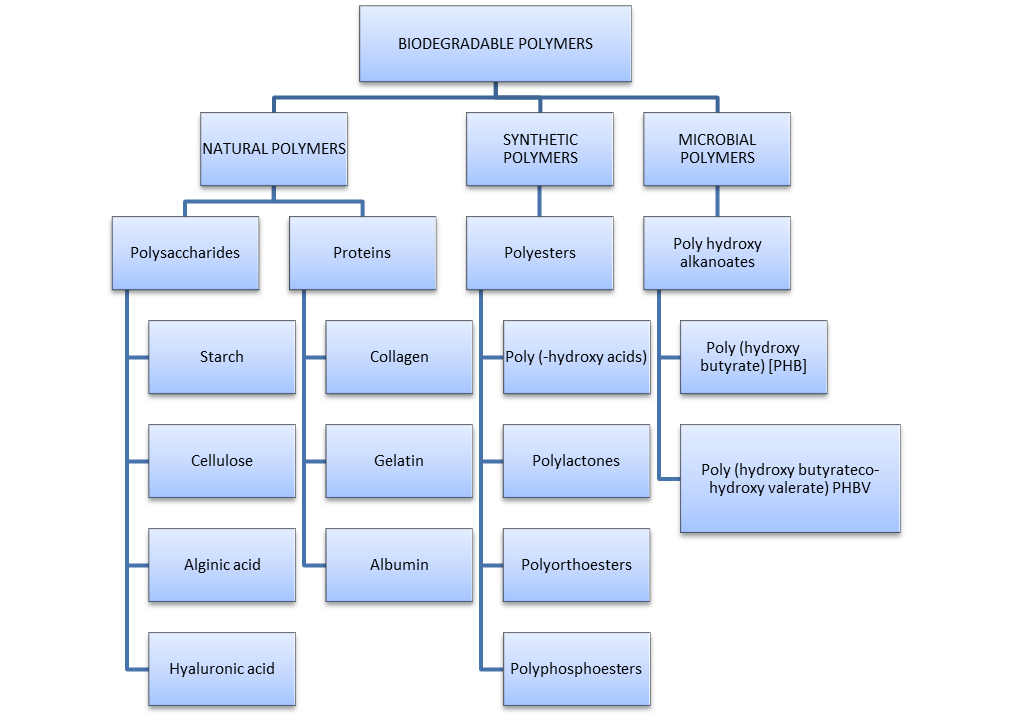

Classification:

Figure 1: Classification of biodegradable polymer

Starch: One well-known hydrocolloid biopolymer is starch. It is one of the most affordable biodegradable polymers and a low-cost polysaccharide that is widely accessible. Typically, starch is utilised as a thermoplastic. Agricultural plants synthesise hydrophilic starch in the form of granules. The primary sources of starch extraction include potatoes, corn, wheat, and rice. It is made up of two types of polymers: amylopectin (poly-?-1, 4-Dglucopyranoside and ?-1, 6D-glucopyranoside) and amylose (poly-?-1, 4-Dglucopyranoside), which is a branching and amorphous polymer. Depending on the source, starch contains varying amounts of amylose and amylopectin, ranging from 10–20% amylase and 80–90% amylopectin. Amylose has a helical shape and dissolves in water. [11]

Polylactic acid (PLA): Typically, lactide, a cyclic dimer of lactic acid, is polymerized by ring opening polymerization or polycondensation of D- or L-lactic acid to produce PLA. There are two types of lactide: L-lactide and D-lactide. L-lactide is the natural isomer, and DL-lactide is the synthetic mix. Various other synthetic techniques have also been investigated. Because PLA has –CH3 side groups, it is a hydrophobic polymer. Because of the methyl side groups' steric shielding effect, it is more resistant to hydrolysis than PGA.[11] By using ring opening polymerization, high molecular weight PLAs can be synthesised. By changing the ratios of the two enantiomers, this method also enables control over the final PLA characteristics. Additional pathways include chain extension reactions, solution polymerization, and melt/solid state polymerization. PLA with a high molecular weight exhibits superior mechanical qualities. [5]

Collagen: It is derived from a variety of animals, including humans, horses, pigs, and cows, and it has numerous biological uses. Fibroblasts, which are derived from pluripotent adventitial cells or reticulum cells, synthesise collagen. Collagen can be divided into several groups, such as classical fibrillar and network-forming collagens, collagens associated with fibrils that have interrupted triple helices, collagens connected with membranes that have interrupted triple helices, and collagens with multiple triple-helix domains and interruptions. Selecting a specific collagen for a certain application is aided by its amino acid content and sequencing. [2][28-30]

Plant oil nanocomposites: The creation of plant oil/clay nanocomposites through the curing of epoxidized soybean oils (ESO) in the presence of organophilic MMT is the greatest example.In order to boost the thermal stability of the nanocomposites, it was discovered that the additive was randomly mixed and intercalated into the polymer matrix. The additive also resulted in a homogenous structure of organic and inorganic materials. Following dynamic viscoelasticity analysis (DVA), it was established how clay incorporation's reinforcing effect resulted from silica nanolayers' increased surface area and high aspect ratio. [19]

Polyhydroxybutyrate (PHB): PHB is an uncommon instance of a biocompatible and biodegradable hydrophobic polymer. Its crystalline degree is almost 80%, and it has a high melting point of 170-180 °C. PHB is brittle and stiff; the degree of fragility depends on the polymer's microstructure, glass transition temperature, and recrystallization. It grows increasingly brittle the longer it is stored. Its broader application is restricted by thermal instability that arises from continuous high-temperature polymer manufacturing as well as its propensity to fracture. Addition of various nucleation agents improves the mechanical and thermal properties. The most often used technique for altering the initial characteristics of PHB is unquestionably the mixing of the main polymer component with additives or other polymers. PHB is generally available for use since it can be processed using standard technological procedures for processing plastics. [9,31,32]

Polycaprolactone (PCL): PCL is a semicrystalline aliphatic polyester that has a high degree of biocompatibility and a delayed rate of biodegradation. Ring opening polymerization of ?-caprolactone using a variety of anionic and cationic catalysts yields PCL. It is appropriate for the creation of prolonged-release delivery systems because of its delayed biodegradation.

Its hydrophobicity is the primary issue, but it can be resolved by mixing it with other man-made or natural polymers to enhance its mechanical characteristics and biocompatibility. [9]

Biological Materials & Biodegradable Plastics: Four major feedstock categories provide naturally existing biopolymers (Tharanathan 2003). Collagen and gelatine come from animal sources, whereas chitin, which is converted to chitosan, comes from marine sources. Scientists are focusing their attention primarily on the remaining two feedstock categories, which are seen the most promising for future growth and development. Polyhydroxy alkenoates (PHA) and polylactic acid (PLA) can be produced from microbial biopolymer feedstocks. The last class of agricultural feedstocks is the biopolymer source that the University of Saskatchewan in Saskatoon, Canada, is now studying. This type of polymer belongs to the lipid and fat and hydrocolloid groups.

Fibres that serve as reinforcing fillers are another type of agricultural feedstock utilised in the biopolymer industry. This category contains cellulose, the primary structural element of hemp and flax fibres and a highly polar substance (Bismarck 2002). Strong mechanical qualities, low cost, and biodegradability characterise natural cellulose fibres. Because of these qualities, cellulose fibres are the most often used natural filler in plastic polymers. The second common biopolymer that is created by microbial fermentation is polylactic acid. Lactic acid, which is obtained through fermentation processes, condenses to generate it (Jopski, 1993). A thermoformed, all-natural plastic container made of PLA derived from corn has just been made commercially accessible by Wilkinson Manufacturing Co. (Fort Calhoun, Nebraska, USA). Natural plant sugars are produced by breaking down the carbon contained in plant starches. The PLA is created via separation and fermentation. Because they are not present in nature, PHA and PLA are both regarded as synthetic polymers. But they are completely biodegradable. (Stevens, 2003). [1]

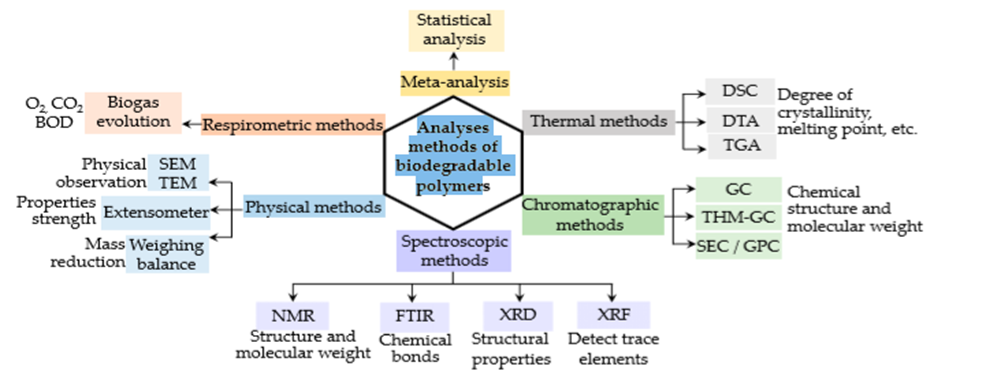

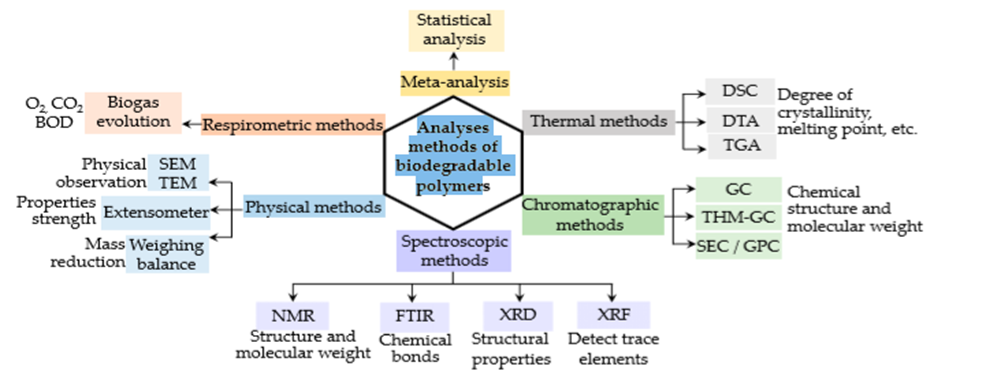

Figure 2 Analytical methods of biodegradable polymers

Analyses methods of biodegradable polymers:[6]

Blends:

- Starch-PLA: Because of their incompatibility, starch and PLA blends made with traditional methods have poor mechanical characteristics. During the extrusion process, plasticizers or reactive agents can be used to promote elongation. Coupling agents have been employed, such as isocyanates. The isocyanate group and the hydroxyl groups in starch may react to form urethane bonds, which would make these systems compatible. Additionally, the impact of starch gelatinization was examined. Research indicates that starch may serve as a nucleating agent in PLA/gelatinized starch blends, enhancing the blends' crystallinity and improving their mechanical qualities.[11]

- Starch – PCL: TPS and PCL were combined in order to modify the melt's rheological characteristics prior to the film blowing process, which created the films (Matzinos et al. 2002). One type of starch mix that is produced by Novamont (Italy) has various synthetic ingredients. Mater-Bi® is its trade name. There are four grades available, with PCL (Mater-Bi® Z) making up one of them. The fastest rate of PCL breakdown is possible with the largest concentration of starch. A study was conducted on the behaviour of several starch blends treated with PCL (Yavuz 2003). When modified starch is added, PCL's Young's modulus rises while its tensile strength and elongation at break values fall. Reduced ductility occurs in the blend (Shin et al. 2004). Depending on the applications, several synthetic polymers with a reduced biodegradability are employed to regulate the pace of biodegradation.[11]

- Blend with synthetic degradable polymers: Initially, starch was used by Gryphon as a filler for polyolefin, with quantities ranging from 6 to 15%. A carbon-carbon backbone matrix including starch has been studied in an effort to improve the vinyl polymers' biodegradability. In each of these instances, the surface area that was made available for microbial attack was increased by the usage of starch granules. This technique assumes the use of biodegradable polymers to generate fully biodegradable starch-based composites. Polyvinyl alcohol (PVA), biopolymers, and aliphatic polyesters are typically blended with starch. The two most widely used polyesters are polylactide (PLA) or poly(?-caprolactone) (PCL), which is produced by chemical polymerization, and poly(?-hydroxyalkanoates) (PHA), which is produced by microbiological synthesis. The objective of combining cheap starch with fully biodegradable polyester is to increase its cost competitiveness while preserving other qualities at a respectable level. [33-35] Among the most significant biodegradable polyesters, PLA has many great qualities and is widely used in numerous industries, particularly the biomedical one. PLA has a high modulus and strength and is well-biocompatible and processable. Nevertheless, PLA ages physically over time and becomes extremely brittle when subjected to stress and bend loads. Furthermore, PLA costs a lot more than typical industrial polymers. [7]

Biodegradation of Biopolymers: The polymer first breaks down into its monomers, which are then mineralized, during breakdown. Many factors influence biodegradation, such as the type of organism, the pre-treatment type, and the properties of the polymers. The list of variables influencing the polymer biodegradation rate is displayed in. The properties of the polymer, including its molecular weight, mobility, tacticity, crystallinity, and substitutions in its structure, as well as any plasticizers or additives put to it, all have a significant impact on how quickly the polymer degrades. The following types illustrates the reactions that take place when polymers biodegrade. [36, 37]

- Extrusion: Extrusion is the method used to treat all polymers at a commercial stage. Single screw extrusion and twin-screw extrusion are the two types of procedures. The primary reason single screw extrusion is preferred over twin screw extrusion is its simplicity and reduced cost. Destruct rising is the process by which starch becomes amorphous when exposed to heat and shear. This is the most effective technique for processing biopolymers composed of aliphatic esters since their low melting point makes it challenging to treat them using techniques like film-blowing and blow moulding.

- Film blowing: This is the process that is utilised in the industry to make films out of thermoplastics. Film is forced through a die with a slit, and air is forced through the aperture in the middle of the die. Over a solitary air bubble, the tubular film is cooled, flattened, and extruded once more. Usually, films have a thickness of 0.007–0.125 mm.

- Casting: Using this technique, a molten resin web is drawn from a die onto rollers to cool and create film. The single orientation of the molecular structure and the quick cooling of the film are the causes of the inferior mechanical characteristics of the cast film. [12,38-40]

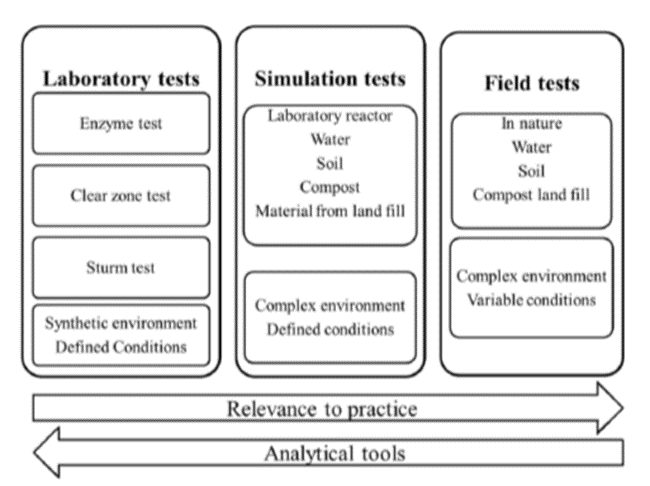

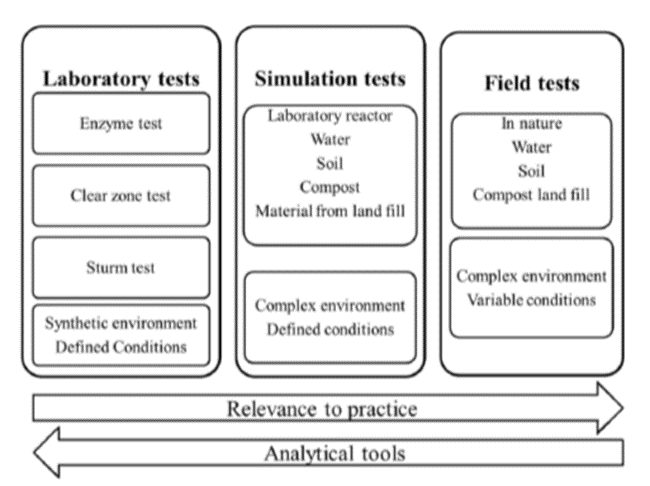

Tests for Biodegradation:

Biodegradable Alternatives To Conventional Plastics: Many bioplastics may be processed using methods commonly employed in the polymer industry, such as compounding, film processing, and moulding, and have mechanical qualities comparable to those of their conventional equivalents, such as PP, PS, and PE. Their use has been observed in numerous applications with short service lives where biodegradability is a crucial benefit, such as consumer packaging (e.g., trays, pots, films, and bottles in food packaging), disposables for convenience food (e.g., cutlery and tableware), bags (for shopping, gardening, or household waste), mulch films for agriculture, personal care disposals (e.g., nappies), and even golf tees. [41, 42]

PLA is 100% biobased, completely biodegradable (although only in specific situations), and may be composted in an industrial setting. It is also environmentally benign. Additionally biocompatible, PLA shouldn't have any harmful or carcinogenic consequences when applied locally to tissues. Its thermal processibility is superior than that of other biopolymers, such PCL. PLA degrades slowly and is also comparatively hydrophobic. Tensile strength and elastic modules are similar to PET. [9]

Self-healing antimicrobial biopolymer film for food packaging: When dynamic molecules like antimicrobial chemicals are infused into food products, their antimicrobial qualities become even more crucial in controlling undesirable microbes. Films have also been modified to include antimicrobial substances for use in active packaging. Because these films rely on dispersion through the packing media rather than a triggered release of antimicrobials via responsive polymers, they are regarded as active. Films infused with antibacterial/antifungal substances like sodium benzoate and benomyl were used in early studies in this field. It has been investigated to use natural antibacterial compounds such as clove, pepper, cinnamon, coffee, and others in both edible and inedible films. Another biologically generated substance, chitosan, has also been extensively studied because of its inherent antibacterial properties and lack of toxicity. According to Rhim et al., chitosan-based nanocomposite films with Ag-Ion and Nano-silver incorporation exhibit antibacterial qualities and improve food safety and quality by lowering the growth of contaminating microorganisms following post-processing. [12,43, 44]

Nanofillers on biodegradable polymer: Nanoparticles are being incorporated into newly developed composite materials for a range of application levels. In the matrix where the bio fibre is chosen as reinforcement, nanoparticles must be added. This particular nanoparticle serves to enhance the material properties of the resultant composite materials, including their optical, mechanical, conductivity, energetics, and surface morphology.

Our forests and farmlands provide the necessary biofibre. The separated portions of the plant biomass, cellulose derived from bacteria, cellulose chemically regenerated from cellulose that is naturally present, and cellulose created by tunicates are all referred to as biofibres. Additionally, these fibres are taken from animals in the form of wool, silk, feathers, and hairs. [17]

- Organic nanofillers: To create a translucent composite film, the polymers were combined with organic nanofillers derived from cellulose. Solvent exchange is used to fill the cellulose nanocrystals that are produced when sulfuric acid is hydrolysed with polycarbonates in organic solutions. The carbonyl group in the polycarbonates and the hydroxyl group in the cellulose nanocrystal create a hydrogen connection. Chitin and CS nanoparticles are increasingly widely used as organic nanofillers due to their high film-forming ability, high surface area, non-toxicity, and biocompatibility.[22]

- Inorganic nanofillers: With their exceptional mechanical, thermal, chemical, biological, and physical qualities, these nanofillers have a great deal of potential as active fillers. The resulting biofiber composite films perform better overall when the metal and metal oxide particles are reinforced with matrix.The primary focus while choosing inorganic fillers is on many attributes, including structural, electrical, and electronic qualities. The structural, thermal, rheological, and physical properties of the polymers were found to be enhanced by the addition of these fillers. The use of inorganic filler elements increased the common metrics of polymers, including elongation at break (EAB), impact strength, tensile strength, and stiffness value.[23]

Properties of Polymer Nanocomposites:

- Antimicrobial properties: For a variety of uses, particularly in the packaging sectors, the antibacterial qualities of the biopolymer reinforced composites were often investigated. The antibacterial qualities of nanocellulose (NCL)/CMC and nano chitosan (NCH)/CMC nanocomposites were compared by Jannatyha et al. The presence of nanofillers in NCH/CMC nanocomposites resulted in the high antibacterial capabilities observed, while the inhibitory zone was absent from NCL/CMC composites and plane CMC film. In nanocomposites, the inhibitory effect was greater against S. aureus and less against E. Coli. This outcome demonstrates that additional NCH moves from the matrix film into the surrounding area and inhibits the tested microorganisms.[24]

- Mechanical properties: Without nanomaterial reinforcement, biodegradable polymer packaging materials have demonstrated subpar mechanical qualities. In a study, Puglia and colleagues reinforced ternary polymeric films of PLA and grafted PLA (g-PLA) at two different weight percentages (1 and 3%) using cellulose nanocrystals (CNC) and lignin nanoparticles (LNP). Higher modulus and tensile strength values were found in PLA-1LNP/3CNC compared to PLA-3LNP/1CNC, indicating that different combinations of nanofillers with the same weight might have distinct enhancing properties. [45]

Biodegradable Polymer-Based Drug-Delivery Systems for Ocular Diseases: A wide range of conditions that could impair vision can affect the anterior and posterior portions of the eye. Notably, the anterior segment is primarily affected by diseases such as glaucoma, anterior uveitis, and ocular surface ailments like keratoconjunctivitis and dry eye disease. On the other hand, disorders such as diabetic retinopathy, age-related macular degeneration, and retinal vascular occlusions often impair the posterior region. Biodegradable DDSs have garnered increased interest recently, which is indicative of their potential for treating a range of ocular ailments. They offer opportunities for focused and targeted drug delivery, enhance drug stability and bioavailability, and enable a tailored and sustained release of therapeutic substances. As a result, there is a decrease in systemic side effects and an overall improvement in medication efficacy.[16]

- Glaucoma: Glaucoma is one of the main causes of permanent blindness in the world. The disease is primarily linked to increased intraocular pressure (IOP), which is frequently caused by reduced aqueous humour outflow. Even though glaucoma is quite frequent, its pathophysiology is still complicated and poorly understood. Because IOP is the sole modifiable risk factor at this time, the majority of the medicinal and surgical therapies that are now available are aimed at decreasing it. The first-line therapy for glaucoma is often pharmacological, including beta blockers, prostaglandin analogues, alpha agonists, and carbonic anhydrase inhibitors. However, the difficulty of repeated doses, local side effects, and the asymptomatic nature of early-stage glaucoma frequently result in patient noncompliance. [20,46-48]

- Anterior Uveitis: An inflammatory disease called uveitis affects the uveal tract, which includes the choroid, ciliary body, and iris. Redness, discomfort, sensitivity to light, impaired vision, and floaters are common symptoms. Uveitis is divided into four categories: anterior, intermediate, posterior, and panuveitis, depending on which area of the uvea is afflicted. It can be acute, recurring, or chronic, and it can happen at any age. The underlying reason may be idiopathic, autoimmune illnesses, infections, or trauma, among many other possibilities. The course of treatment frequently involves the use of corticosteroids, other immunosuppressive medicines, and anti-inflammatory drugs.[21,49,50]

- Dry Eye Disease: Dry eye disease (DED) is classified as a complicated disorder affecting the ocular surface, which destabilises the tear film and causes symptoms connected to the eyes, according to the most current 2017 update from the Tear Film and Ocular Surface Society's International Dry Eye Workshop. The study highlights the critical roles that neurosensory abnormalities, inflammation, tear film variations, hyperosmolarity, and damage to the ocular surface play in the development of DED. It may also occasionally be linked to systemic diseases including lupus, rheumatoid arthritis, or Sjögren's syndrome. [25,51,52]

Manufacturing of biobased food packaging: Understanding the processing and material characteristics of the polymers is necessary for the engineering of a biobased package or packaging material. A specific modification of the polymer is necessary if the original biopolymer's characteristics differ from the necessary ones or if the polymer isn't naturally thermoplastic. Even after adjustments, it is doubtful that one polymer will be able to supply all the necessary qualities for highly particular needs (very low gas permeability or strong water resistance). As a result, a composite, laminate, or co-extruded material must contain a variety of components. [11]

Possible products produced of biobased materials: Most biobased polymers that have been previously discussed have the same basic repeating chemical units as a large portion of conventional plastics. Therefore, in the broadest sense, proteins (repeating peptide functionality) can be thought of as the synthetic polyamides, polylactic acid is just one example of the diverse group of polyesters, and poly-saccharides with repeating acetal functionality can be thought of as the naturally occurring analogues of the synthetic polyacetals.

- Blown (barrier) films

- Thermoformed containers

- Foamed products

- Coated paper

Since the 18th century, when the food business first emerged, the packaging sector has undergone significant advancements, with the most significant and clever changes taking place in the last century. Food safety and quality have increased as a result of these developments. The majority of inventions have been fueled by shifting customer tastes, however some have come from unexpected places. The majority of the recent developments have gone towards slowing down oxidation and managing moisture migration, microbial development, respiration rates, and volatile flavours and scents. This focus is similar to that of food packaging distribution, which has sparked changes in the important domains of sustainable packaging, competitive advantage via the utilisation of packaging value chain interactions, and the changing role of food service packaging. Biopolymers have had a significant impact on packaging.

Biodegradable and biocompatible polymers in bone and muscle tissue engineering: The body has a variety of tissue types, each with distinct ECM compositions and structural traits. The capacity to tailor the scaffold's properties is particularly beneficial when considering the type of tissue that has to be replaced. Bones provide more strong physical stability and a greater ECM:cell ratio, mostly composed of collagen, supporting and shielding the body. However, the requirement for skin and muscles to stretch as opposed to exerting such mechanical strength results in an increase in the ECM's elastin component. To improve the efficiency of movement, ligaments and tendon flexibly transfer loads between muscles and bones by expanding and contracting. They must have high mechanical and tensile strength, which may be achieved with plenty of collagen structures that are aligned. [13, 53, 54] The unique requirements of tissue scaffolds in terms of biocompatibility and biodegradability, as well as the intricate relationships between them inside the human body, present unique challenges for this field of study. Not only should a scaffold function and decompose appropriately, but it should also do so for the appropriate tissue type, as each has unique mechanical and morphological requirements. While a low dispersion is desirable, the kind of tissue affects other characteristics as well, such as strain values, Tg, and crystallinity. The kinetics of polymer breakdown need to be controlled to avoid breaks and inflammation throughout the healing process. [55, 56]

CONCLUSIONS:

Biodegradable polymers with the essential qualities of both biodegradability and biocompatibility have demonstrated their versatility and great potential in the biomedical arena. The market's move towards biomaterials is a reflection of the enormous amount of work that has gone into creating these polymers. The significance of these remarkable materials is demonstrated by their applications in a wide range of fields, including tissue regeneration, enzyme immobilisation, controlled medication administration, gene transfer, and surgical sutures and wound dressing. The development of innovative approaches for a range of therapies is facilitated by the introduction of biomaterials based on biodegradable polymers and their ability to overcome related drawbacks. Significant advancements in this field, such as Nab technology, and the ongoing growth of research in this area are examples of the important contributions these polymers have made.

REFERENCE

- Kolybaba, M., et al. "Biodegradable polymers: past, present, and future." ASABE/CSBE north central intersectional meeting. American Society of Agricultural and Biological Engineers, 2006.

- Doppalapudi, Sindhu, et al. "Biodegradable polymers—an overview." Polymers for Advanced Technologies 25.5 (2014): 427-435.

- Kotwal, V. B., et al. "Biodegradable polymers: Which, when and why." Indian J. Pharm. Sci 69.5 (2007): 616-625.

- Marin, Edgar, Maria Isabel Briceño, and Catherina Caballero-George. "Critical evaluation of biodegradable polymers used in nanodrugs." International journal of nanomedicine (2013): 3071-3091.

- Vroman, Isabelle, and Lan Tighzert. "Biodegradable polymers." Materials 2.2 (2009): 307-344.

- Baidurah, S. (2022, November 15). Methods of Analyses for Biodegradable Polymers: A Review. Polymers, 14(22), 4928. https://doi.org/10.3390/polym14224928

- Lu, D. R., C. M. Xiao, and S. J. Xu. "Starch-based completely biodegradable polymer materials." Express polymer letters 3.6 (2009): 366-375.

- Nair, Lakshmi S., and Cato T. Laurencin. "Biodegradable polymers as biomaterials." Progress in polymer science 32.8-9 (2007): 762-798.

- ?olnik, Maja, et al. "Biodegradable polymers, current trends of research and their applications, a review." Chemical industry and chemical engineering quarterly 26.4 (2020): 401-418.

- Laycock, Bronwyn, et al. "Lifetime prediction of biodegradable polymers." Progress in Polymer Science 71 (2017): 144-189.

- Siracusa, Valentina, et al. "Biodegradable polymers for food packaging: a review." Trends in food science & technology 19.12 (2008): 634-643.

- Mangaraj, S., et al. "Application of biodegradable polymers in food packaging industry: A comprehensive review." Journal of Packaging Technology and Research 3 (2019): 77-96.

- Khalili, S., Khorasani, S., Razavi, S., Hashemibeni,B., and Tamayol, A. Nano? brous scaffolds with biomimetic composition for skin regeneration, Applied Biochemistry and Biotechnology 2019; 187 (4): 1193– 1203 DOI: 10.1007/s12010-018-2871-7

- Tawade, Pratik, Nimisha Tondapurkar, and Akash Jangale. "Biodegradable and biocompatible synthetic polymers for applications in bone and muscle tissue engineering." Journal of Medical Science 91.3 (2022): e712-e712.

- Roy, Soumili, Kulwinder Singh, and Abhishek Kumar. "Biodegradable polymer nanocomposites for active food packaging." E3S Web of Conferences. Vol. 509. EDP Sciences, 2024.

- Tsung, Ta-Hsin, et al. "Biodegradable Polymer-Based Drug-Delivery Systems for Ocular Diseases." International Journal of Molecular Sciences 24.16 (2023): 12976.

- Jagadeesh, Praveenkumara, et al. "Influence of nanofillers on biodegradable composites: A comprehensive review." Polymer composites 42.11 (2021): 5691-5711.

- Souza, Victor Gomes Lauriano, and Ana Luisa Fernando. "Nanoparticles in food packaging: Biodegradability and potential migration to food—A review." Food Packaging and Shelf Life 8 (2016): 63-70.

- Bari, Sarang S., Aniruddha Chatterjee, and Satyendra Mishra. "Biodegradable polymer nanocomposites: An overview." Polymer Reviews 56.2 (2016): 287-328.

- Lavik, Erin, M. H. Kuehn, and Y. H. Kwon. "Novel drug delivery systems for glaucoma." Eye 25.5 (2011): 578-586.

- Muñoz-Fernández, Santiago, and Emilio Martín-Mola. "Uveitis." Best Practice & Research Clinical Rheumatology 20.3 (2006): 487-505.

- Khalil, H. P. S. A., Rus Mahayuni, A. R., Bhat, I. U. H., Rudi, D., Almulali, M. Z., & Abdullah, C. K. (2012, October 17). CHARACTERIZATION OF VARIOUS ORGANIC WASTE NANOFILLERS OBTAINED FROM OIL PALM ASH. BioResources, 7(4). https://doi.org/10.15376/biores.7.4.5771-5780

- Hemath, M., Mavinkere Rangappa, S., Kushvaha, V., Dhakal, H. N., & Siengchin, S. (2020, July 14). A comprehensive review on mechanical, electromagnetic radiation shielding, and thermal conductivity of fibers/inorganic fillers reinforced hybrid polymer composites. Polymer Composites, 41(10), 3940–3965. https://doi.org/10.1002/pc.25703

- Yang, W., Fortunati, E., Dominici, F., Giovanale, G., Mazzaglia, A., Balestra, G., Kenny, J., & Puglia, D. (2016, June). Synergic effect of cellulose and lignin nanostructures in PLA based systems for food antibacterial packaging. European Polymer Journal, 79, 1–12. https://doi.org/10.1016/j.eurpolymj.2016.04.003

- Craig, Jennifer P., et al. "TFOS DEWS II definition and classification report." The ocular surface 15.3 (2017): 276-283.

- Modi, G., Pillay, V., & Choonara, Y. E. (2010, January). Advances in the treatment of neurodegenerative disorders employing nanotechnology. Annals of the New York Academy of Sciences, 1184(1), 154–172. https://doi.org/10.1111/j.1749-6632.2009.05108.x

- Godin, B., Sakamoto, J. H., Serda, R. E., Grattoni, A., Bouamrani, A., & Ferrari, M. (2010, May). Emerging applications of nanomedicine for the diagnosis and treatment of cardiovascular diseases. Trends in Pharmacological Sciences, 31(5), 199–205. https://doi.org/10.1016/j.tips.2010.01.003

- Friess, W. (1998, March). Collagen – biomaterial for drug delivery1Dedicated to Professor Dr. Eberhard Nürnberg, Friedrich-Alexander-Universität Erlangen-Nürnberg, on the occasion of his 70th birthday.1. European Journal of Pharmaceutics and Biopharmaceutics, 45(2), 113–136. https://doi.org/10.1016/s0939-6411(98)00017-4

- Gelse, K. (2003, November 28). Collagens—structure, function, and biosynthesis. Advanced Drug Delivery Reviews, 55(12), 1531–1546. https://doi.org/10.1016/j.addr.2003.08.002

- Khan, W., Muthupandian, S., Farah, S., Kumar, N., & Domb, A. J. (2011, November 3). Biodegradable Polymers Derived From Amino Acids. Macromolecular Bioscience, 11(12), 1625–1636. https://doi.org/10.1002/mabi.201100324

- Lee, S. Y. (1996, January 5). Bacterial polyhydroxyalkanoates. Biotechnology and Bioengineering, 49(1), 1–14. http://dx.doi.org/10.1002/(sici)1097-0290(19960105)49:1<1>3.3.co;2-1

- Avella, M., Errico, M., Laurienzo, P., Martuscelli, E., Raimo, M., & Rimedio, R. (2000, May). Preparation and characterisation of compatibilised polycaprolactone/starch composites. Polymer, 41(10), 3875–3881. https://doi.org/10.1016/s0032-3861(99)00663-1

- Griffin G. J. L.: Biodegradable synthetic resin sheet material containing starch and a fatty material. U.S. Patent: 4016117, USA (1977).

- Bikiaris D., Prinos J., Koutsopoulos K., Vouroutzis N., Pavlidou E., Frangis N., Panayiotou C.: LDPE/ plasticized starch blends containing PE-g-MA copolymer as compatibilizer. Polymer Degradation and Stability, 59, 287–291 (1998).

- Mani R., Bhattacharya M.: Properties of injection moulded blends of starch and modified biodegradable polyesters. European Polymer Journal, 37, 515–526 (2001).

- ASTM F1927 (2014) Standard test method for determination of oxygen gas transmission rate, permeability and permeance at controlled relative humidity through barrier materials using a coulometric detector, 2007. ASTM International, West Conshohocken.

- Krasnova I, Dukalska L, Seglina D, Juhnevica K, Sne E, Karklina D (2012) Effect of passive modified atmosphere in different packaging materials on fresh-cut mixed fruit salad quality

- Krasnova I, Dukalska L, Seglina D, Juhnevica K, Sne E, Karklina D (2012) Effect of passive modified atmosphere in different packaging materials on fresh-cut mixed fruit salad quality.

- Averous L, Pollet E (2012) Environmental silicate nano-biocomposites. Springer, London

- Mangaraj S, Goswami TK, Panda DK (2015) Modeling of gas transmission properties of polymeric films used for MA Packaging of fruits. J Food Sci Technol 52(9):5456–5469

- H. Rosenheim, I. De, S. Hyvedemm, Bioplastics market data 2017, https://docs.european-bioplastics.org/publications/market_data/2017/Report_Bioplastics_Market_Dat a_2017.pdf (accessed 9 June 2019)

- S. Farah, D.G. Anderson, R. Langer, Adv. Drug Deliv. Rev. 107 (2016) 367–392

- Kruijf ND, Beest MV, Rijk R, Sipilainen-Malm T, Losada PP, Meulenaer BD (2002) Active and intelligent packaging: applications and regulatory aspects. Food Addit Contam 19(suppl 1):144–162

- Seydim AC, Sarikus G (2006) Antimicrobial activity of whey protein based edible films incorporated with oregano, rosemary and garlic essential oils. Food Res Intl 39(5):639–644

- W. Yang, E. Fortunati, F. Dominici, G. Giovanale, A. Mazzaglia, G. M. Balestra, J. M. Kenny, and D. Puglia, Eur Polym J 79, 1 (2016)

- Flaxman, S.R.; Bourne, R.R.A.; Resnikoff, S.; Ackland, P.; Braithwaite, T.; Cicinelli, M.V.; Das, A.; Jonas, J.B.; Keeffe, J.; Kempen,J.H.;etal. Globalcausesofblindnessanddistancevisionimpairment1990–2020: Asystematicreviewandmeta-analysis. Lancet Glob. Health 2017, 5, e1221–e1234

- Lavik, E.; Kuehn, M.H.; Kwon, Y.H. Novel drug delivery systems for glaucoma. Eye 2011, 25, 578–586.

- Patel, H.Y.; Danesh-Meyer, H.V. Incidence and management of cataract after glaucoma surgery. Curr. Opin. Ophthalmol. 2013, 24, 15–20

- Wu, W.; He, Z.; Zhang, Z.; Yu, X.; Song, Z.; Li, X. Intravitreal injection of rapamycin-loaded polymeric micelles for inhibition of ocular in?ammation in rat model. Int. J. Pharm. 2016, 513, 238–246.

- Gonzalez-Pizarro, R.; Carvajal-Vidal, P.; Bellowa, L.H.; Calpena, A.C.; Espina, M.; García, M.L. In-situ forming gels containing ?uorometholone-loaded polymeric nanoparticles for ocular in?ammatory conditions. Colloids Surf. B Biointerfaces 2019, 175, 365–374.

- O’Neil, E.C.; Henderson, M.; Massaro-Giordano, M.; Bunya, V.Y. Advances in dry eye disease treatment. Curr. Opin. Ophthalmol. 2019, 30, 166–178.

- Messmer, E.M. The pathophysiology, diagnosis, and treatment of dry eye disease. Dtsch. Arztebl. Int. 2015, 112, 71–81.

- Beldjilali-Labro, M., Garcia, A., Farhat, F., Bedoui, F.,Grosset, J-M., Dufresne, M., and Legallais, C. Biomaterials in tendon and skeletal muscle tissue engineering: current trends and challenges, Materials 2018;11: 1–49 DOI: 10.3390/ma11071116

- Sensini, A., Massafra, G., Gotti, C., Zucchelli, A., and Cristofolini, L. Tissue engineering for the insertions of tendons and ligaments: an overview of electrospun biomaterials and structures, Frontiers in Bioengineering and Biotechnology 2021; 9: 1–23 https:// doi.org/10.3389/fbioe.2021.645544

- Badylak, S. The extracellular matrix as a scaffold for tissue reconstruction, Seminars in Cell and Developmental Biology 2002;13 (5): 377–83 DOI:10.1016/ s1084952102000940

- Martina, M. and Hutmacher D. Biodegradable poly-mers applied in tissue engineering research: A review, Polymer International 2007; 56 (2): 145–57 https:// doi.org/10.1002/pi.2108

Tanmay Mohanta*

Tanmay Mohanta*

Shubhra Tarafdar

Shubhra Tarafdar

Shivani Raj

Shivani Raj

10.5281/zenodo.12739641

10.5281/zenodo.12739641