The advance sustainable application bio-polymers development in pharmaceutical research and development. Now recent and Today's technological aided the bio polymer end products to higher purposes. The motive of this paper is to basics and light on some aspects of bio-polymers that include its classes, properties, composites design using linked polymer-polymer and applications. The depending on the type of class and sub class on the basis of various aspects of categories, many enthralling chemistry of polymer composition can be modified and substantiated. The Bio-polymers and its composites have introduced captivating to impressions in regions of Pharmaceuticals, Chemicals, Polymer Science, biomedical, Long Circulatory Modified Applications, packaging, agricultural and based automotive applications. Although their efficacy is yet to reach their fossil- fuel counterparts, bio-polymers have laid role a distinguishing mark on that will continue to inspire modified creation of novel substances for many years to come. The Essential properties can imparted to the ensuing bio polymer by altering, modifying its chemical configuration and process, method of synthesis while also focusing on its functional application purposes.

Biopolymer, Design Chemical Sketch Tool, Matrix, Chem Axon

1.1 Concept of Bio-polymer

The ‘bio’ in the term ‘polymerize signifies that these polymers are produced from biological living matter. Chemically chain-like structured molecules either linearly, composite or branched/cross-linked, bio-polymers have found their way into revolutionizing the world of bio materials. The group of monomer units of most bio-polymers usually consists molecules of either nucleic acid of nucleotide, amino acid proteins or saccharine derived from sugars.

1.2 Properties of bio-polymers

It is characteristic for bio-polymers properties diverging into three chief categories namely relative properties, self-reflected by the polymer, synthesizing properties, the defining the qualities during development and component properties, referring to its functional application capabilities. Properties from each of these three classes are in differentiation with one another, forming a desirable chemical entity.

1.3 Bio-polymer composites

Bio-polymers have remarkable fabricating products that pose value in today's globalization market owing to their renew ability and eco-friendly in terms of biodegradability. Depending on the purpose and practical efficiency, self-reflective properties of bio materials are considered after which several properties are imparted to the ensuing component either during the synthesis. The significant control has been demonstrated by present day's research facilities to bio-polymer composites. Polymer composites combine material attributes of two or more bio or synthetic materials that distinct phases and/or chemical modified constituents to generate one component with desired significant properties. In terms of applicable generality, there are usually three categories of polymer composites first particle reinforced composites that exhibit a strong matrix relationship between two suspended materials; second is sandwich composite hence structures of two distinctive chemical modified materials, whose layers are combined with one another to formation of sustainable application and release pattern.

1.4 Sustainable and functional applications of bio-polymer and its composites

The Bio-polymers are found considerable portion and produce, particularly in the scope of pharmaceuticals, nutraceutical, medical, chemical, polymeric application, plastic industry, agricultural and goods packaging or organizational fields. The biomedical applications draw the remarkable attention for bio-polymer utilization in comparison to other areas because they possess their higher entity significance.

1.5 Implantable Polymer

5.6 Implantable Polymer Types

Implantable polymers can be based on sustainable duration in the body and range from short-term less than (<30>30 days) to permanent.

1.6.1 Long-Term Implantable Polymers

The Long-term implantable polymer applicable by bio-durable (non-resorbable) entity such as polyethylene for limited structural use applications and polyketonesfor spinal applications.

1.6.2 Bioresorbable Polymers

Bioresorbable polymers are chemically metabolized by the human body system after implantation and include polylactide, polyglycolide and co-polymers of Polylactide/Polyglycolide. These materials can be tailored to meet mechanical performance and resorption rates for non-structural drug delivery to resorbable like an anchor.

1.6.3 Implantable Polymer Additives

Implantable delivery of polymers enhanced to modify application performance with biomedical additives that provide visibility under x-ray or stimulate bone growth.

1.7 Bone Mineral

The Phase of pure ? Tricalcium phosphate (TCP) is an osteoconductive and bio-compatible additive that can be melt blended with bio-resorbable polymers, such as PLA for the stimulation of bone growth. Alternatively, hydroxyapatite (HA) may also be blended with bioresorbable polymers (PLLA) for biphasic applications including interference screws used in anterior cruciate ligament (ACL) reconstruction.

1.8 Radiopaque Fillers

Polymers are inherently transparent to x-ray imaging and require specific additives to achieve visibility. Radiopaque filler selection depends on end application and intended implantation time. For more information, please refer to Radiopaque Compounds.

1.9 Advanced polymers using topo-chemical polymerization:

1.9.1 Ladder polymers:

The two paralleled routinely used continuing of bio-based polymer interchanged monomer of chains connect to each other periodically by a Bond of electronegative and positive charge of electrophile and nucleophiles by Hydrogen linked covalent linker. Composite Ladder polymers are attractive as they possess enhanced thermal or mechanical stabilities compared to common single[1]stranded linear chain polymers

GENERAL TERMINOLOGY, METHODOLOGY AND DESIGN:

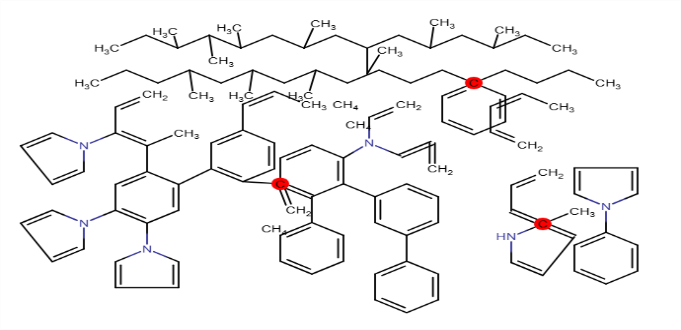

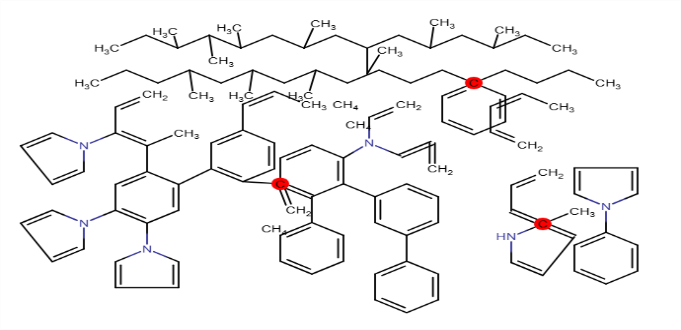

The Novel approach and applications of newly bio polymer or nanoclaying matrix composites emerged in now years, due to their advantages of engineering chemical properties such as low density, high damping, high specific strength and stiffness, high fatigue endurance, and enhanced thermal behavior of polymeric properties [37]. There are many of the properties of polymers different applications like rheological control agent, food packaging, biomedical applications and drug delivery, waste water Treatment, Other Applications includes the silane agents enhanced the adhesion force and hysteresis force of the composites and reduced the friction of coefficient significantly and specified manner. The thermoplastic olefin (TPO) or nanoclaying composites most be lighter than conventional automotile parts, have specific mechanical properties and may be used for external automotive application to the body parts [35,36]. The modified composite coating getting self-extinguishing behavior properties and a capability to significantly reduce the total modified release and the peak enthalpy release rate. It has potential to modify the fire safety of polyurethane foams of the products. The tentative composite biopolymer of Polymer-Polymer design using Chemical Sketch Tool- RCSB PDB, refer figure no: 1 and classification refer figure no: 2

Figure 1. Tentative Composite Polymer-Polymer Design by (Chem Axon) using Chemical Sketch Tool- RCSB PDB

Dr. Santosh Dattu Navale*

Dr. Santosh Dattu Navale*

10.5281/zenodo.14634539

10.5281/zenodo.14634539