Topical drug delivery refers to the administration of a medication-containing substance onto the skin for the direct treatment of skin disorders. This method typically involves the use of topical products such as ointments, creams, and lotions; however, these formulations often present drawbacks, including stickiness, discomfort upon application, limited spreading capacity, and the requirement for rubbing during application. Additionally, they may encounter stability issues. To address these challenges, there has been a growing preference for transparent gels in pharmaceutical as well as cosmetic applications. Emulgels are typically a mixture of gel and emulsion. Emulsions can be either water-in-oil or oil-in-water. They are gelled by adding a gelling agent, and the resulting emulsified gel is the best vehicle for hydrophobic or poorly water-soluble drugs. A wide range of pharmacological dosage forms, such as semisolids, liquid preparations, sprays, and solid powders, are used in topical drug delivery systems. Some major types of semisolid preparation are creams, gels, oinments, lotions, foams, transdermal patch. (1.2)

Physiology of Skin

Figure 1: Physiology of Skin

Epidermis

The epidermis is the skin's outermost layer and serves as a barrier to keep the environment out. It is mostly made up of keratinocytes, which create the keratin protein, which gives the structure strength and waterproofing. Melanocytes, which produce melanin, the pigment that gives skin its color and protects it from UV light, are also found in the epidermis.

Dermis

This is the layer of tissue that lies deeper than the epidermis and is made up of several loose connective tissues. It is mostly made up of collagen, which gives the skin its flexibility and strength as well as providing structural support. In addition, it controls body temperature, binds water to the skin, and protects the body from harm. Another rate-limiting stage in the skin's medication absorption process is the dermis.

Hypodermis

This is also referred to as the subcutaneous tissue; it is the fat depot beneath the skin, composed of loose connective tissues that include secretion pores, cutaneous nerves, and blood vessels. It is not commonly believed that subcutaneous tissue acts as a barrier to medication absorption because drug absorption might take place before the substance passes through the subcutaneous tissues. On the other hand, it has been noted that the adipose tissue depot functions as a drug reservoir, releasing medicines gradually into the circulation of the body. (3)

Fig 2: structure of Emulgel

Emulgel:

Emulgel's name simply indicates that it includes gel and emulsion. Various drugs are able to applied topically to the skin using emulsions that are either water-in-oil or oil-in-water in composition. An emulgel forms when the gelling ingredient is present in the water phase of a traditional emulsion. They can also penetrate the skin very effectively. Emulgel in Dermatological use have several properties such as Thixotropic, greaseless, easily spreadable, readily removable, emollient, non-staining, water-soluble, longer shelf life, bio-friendly, translucent, and visually attractive in terms of medication.(3)

Types of emulgel:

Oil-in-Water (O/W) Emulgel:

This kind of emulgel has scattered oil droplets within a continuous phase of water. O/W emulgels can improve the solubility and bioavailability of lipophilic substances, which is why they are frequently employed to deliver hydrophobic medications or active components. Because they are easily spreadable and non-greasy, they are often preferred.

Water-in-Oil (W/O) Emulgel:

W/O emulgels consist of water droplets scattered throughout the continuous phase of oil. Because these emulgels have occlusive qualities and can increase moisture, they are appropriate for administering hydrophilic medications or moisturizing agents. W/O emulgels are good for dry or damaged skin conditions because they are usually more oily and may leave a residue on the skin physical appearance. (4)

Multiple Emulsion Emulgel:

These emulgels have a more complex structure since they have many layers of both oil and water phases. These emulgels can deliver both hydrophobic and hydrophilic drugs because of their improved drug loading capacity and controlled release characteristics. Multiple emulsion emulgels are perfect for long-term therapy since they can deliver sustained drug release for a longer amount of time.

Microemulsion Emulgel:

Surfactants stabilize the finely dispersed oil and water phases found in microemulsion emulgels. These emulgels can increase the solubility and penetration of medications that are not very water soluble. They look transparent or translucent. Because of their improved skin penetration qualities and quick release of drugs, microemulsion emulgels are frequently chosen. (5)

Factors influencing the drug's topical absorption

- Physicochemical Properties of the Drug

- Skin Integrity

- Skin thickness

- Skin integrity

- Skin hydration

- Temperature

- Vehicle

- Concentration of drug

- Physiological condition

Various uses of Emulsions:

- Emulsions are widely used in formulations for topical, oral, and parenteral applications.

- They form the basis of many cosmetic and personal care products, including creams, lotions, serums, and moisturizers.

- Emulsions are essential in food and beverage manufacturing for creating stable suspensions of oil and water-based ingredients.

- Emulsions also play a key role in encapsulating flavors, vitamins, and nutrients in food products to enhance shelf life and bioavailability.

- Emulsions serve as binders and carriers in the formulation of water-based paints, coatings, and adhesives.

- Emulsions are used in the formulation of pesticides, herbicides, and fertilizers to improve dispersion, stability, and efficacy.

- Emulsions find applications in various industrial processes, including metalworking fluids, lubricants, and coolant formulations.

Materials used to prepare emulgel:

To keep the emulsion stable and avoid phase separation, emulsifying agents are important. They aid in the creation of tiny oil droplets that are scattered throughout the aqueous phase. Typical emulsifiers consist of:

Surface-active substances like sodium lauryl sulfate, sorbitan esters, and polysorbates (like the Tween series).

Waxes, either natural or artificial, such as cetyl alcohol, stearyl alcohol, and cetostearyl alcohol, aid in stabilizing the oil-water contact.

Co-surfactants or co-emulsifiers, like propylene glycol or glycerin, can improve the emulsion's consistency and stability.(6)

The gel matrix that gives the emulgel its viscosity and rheological stability is created by gelling agents. Typical gelling agents consist of:

A synthetic polymer that has good suspending characteristics and clarity by swelling in water to produce a viscous gel.

Hydrophilic polymers that create translucent gels with good spreadability, such as hydroxypropyl cellulose (HPC) or hydroxyethyl cellulose (HEC).

Polysaccharides that can thicken and stabilize an emulsion, such as xanthan gum, guar gum, or carrageenan.

- Co-solvents and solvents:

These substances are employed in formulations to dissolve or disperse both lipophilic and hydrophilic ingredients. Typical co-solvents and solvents are as follows:

Purified water aids in the dissolution of hydrophilic components and acts as the main solvent for aqueous phases.

is a frequently used co-solvent that functions as a humectant and improves the solubility of hydrophobic medications.

An alcohol solvent with the potential to cause skin irritation should be used with caution since it can improve medication penetration and solubilize lipophilic substances.(7)

To stop microbiological contamination and increase shelf life, preservatives are added to emulgel compositions.

Typical preservatives consist of:

Often found in topical formulations, methylparaben, propylparaben, and other paraben derivatives are efficient, broad-spectrum preservatives.

- Phenoxyethanol: A preservative with broad antimicrobial activity that is often used as an alternative to parabens.

- Benzalkonium chloride: Often found in ophthalmic preparations, this quaternary ammonium molecule possesses antibacterial characteristics.(8)

- Active Ingredients:

- To achieve the intended therapeutic effect, the emulgel formulation contains active pharmaceutical ingredients (APIs) or therapeutic agents. The type of active component used in an emulgel—such as moisturizers, analgesics, antimicrobials, or anti-inflammatory agents—depends on its intended use.

- Other Excipients:

- Emulgel formulations may contain other excipients to change viscosity, boost stability, increase skin feel, or offer extra functionality. These could include skin conditioning agents, perfumes, colorants, humectants (like glycerin), and antioxidants (like vitamin E).(9,10)

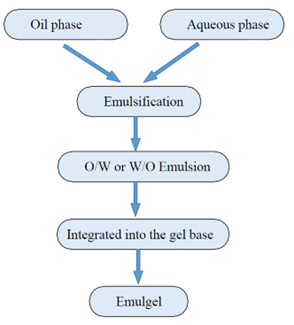

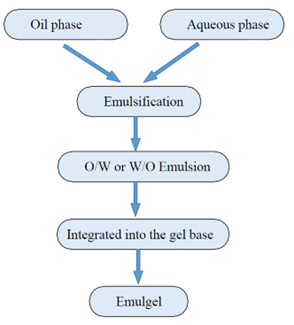

PREPARATION OF EMLGEL

Fig 3: Preparation of Emulgel

Preparation of Oil Phase:

In a beaker combine the lipid(s) and emulsifier Heat the mixture gently to prepare the oil phase.

The mixture should be gradually heated, either in a microwave or in a water bath, until the emulsifier and lipid are completely melted and combined. To ensure homogeneity, thoroughly stir. (11)

To prepare the water phase:

In another container, mix water and any water-soluble additives such as preservatives.

Combine the phases:

Pour the water phase into the oil phase gradually while continuing to mix. Thus, a pre-emulsion is created.

Emulsification:

Using a high-shear mixer (such as a homogenizer or an overhead stirrer), completely emulsify the mixture. In order to generate a stable emulsion, this step is important.

Thickness:

After the emulsion has formed, gradually add the thickening agent to the mixture, stirring constantly to prevent lumps and to get final emulgel.(12)

Evaluation Techniques:

Physical Examination:

The created Emulgel formulation is shown in terms of its physical attributes such as color, uniformity, homogeneity, grittiness, and consistency. Using a thin glass slide and the Emulgel formulation, homogeneity and uniformity are carried out with visual inspection. (13)

Rheological Study:

The viscoelastic characteristics like thixotropy, and stability under shear are determined by using a cone and plate Brookfield viscometer rheological experiments such as oscillatory tests, viscosity measurements, and shear rate are carried out.(14)

Texture Analysis:

Measuring traits such as spreadability, consistency, stickiness, and application ease are all part of texture analysis. For quantitative evaluation, tools such as penetrometers and texture analyzers are Used.(15)

Drug release studies: Drug release kinetics and profile can be measured using methods such as Techniques like Franz diffusion cells or dissolution apparatus.(16)

PH measurement:

Analysis of ph is important criteria for the topical preparation is carried out by Digital PH meter. The pH meter must first be calibrated using a standard buffer solution. After dissolving 1 gram of the formulation in distilled water to create a homogeneous solution, it is set aside for two hours. The glass electrode is immersed in the suspension after two hours, and the pH is then determined.(17)

Microscopic examination:

Microscopic methods such as optical or electron microscopy offer insight on the emulgel matrix's internal structure, particle dispersion, and presence of aggregates or defects.(18)

Compatibility Test:

In order to avoid interactions that can compromise stability or efficacy, compatibility studies are used to evaluate how well the components of the emulgel work with one another and with the packing materials.(19)

Drug Content Determination:

Emulgel's drug concentration was determined using a spectrophotometric technique. By sonicating 1 gram of Emulgel in 100 milliliters of methanol, the amount of celecoxib in the gel was determined (using an Ultrasonic Probe Sonicator). After sonicating and filtering the stock solution, aliquots of varying concentrations were created by appropriately diluting the mixture, and the absorbance was measured at 254 nm using a UV-VIS spectrophotometer. The equation, which was produced by linear regression analysis of the calibration curve, was used to compute the drug content (20)

Skin Irritation Test:

A test for skin irritation was done on the back of a rabbit. A day after application, the test formulation which included were monitored. The following formula was used to determine the overall irritation test results for the optimized formulation.(21)

Primary irritation index = (Erythema reaction scores + Edema reaction scores) / Time interval (h)

Types of Packaging of Emulgel:

- Tube Packaging

- Pump Bottles

- Airless Dispensers

- Jars

- Spray Bottles

- Roll on Applicators

- Foil Packets

- Unit Dose Ampoules

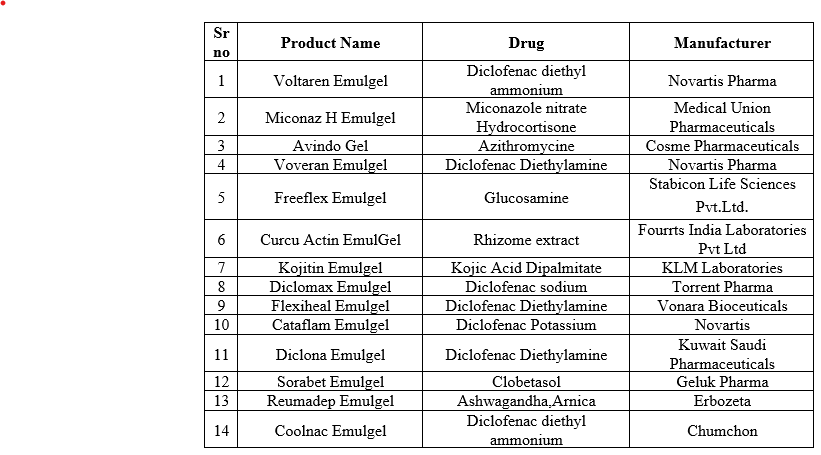

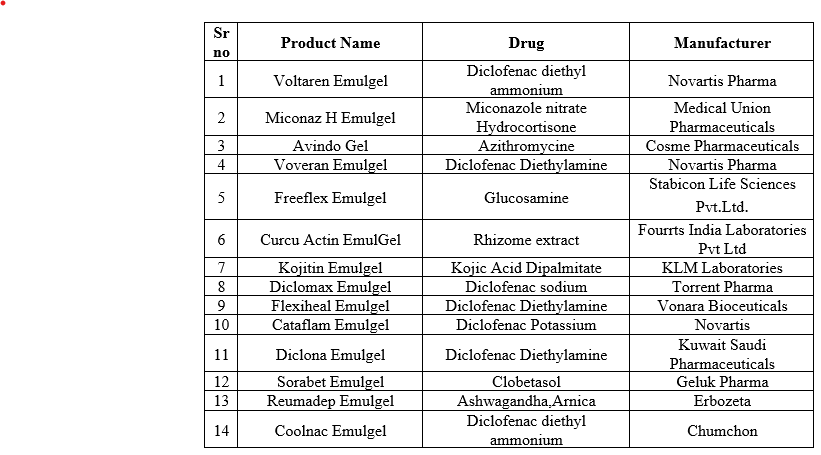

Fig 4: Common Marketed Products of Emulgel

Marketed Products of Emulgl:

Table 1: Present Marketed Formulations of Emulgel

SUMMARY AND CONCLUSION:

Niraj Gaikwad*

Niraj Gaikwad*

Ritesh Aher

Ritesh Aher

10.5281/zenodo.11317649

10.5281/zenodo.11317649