Abstract

Needle-free jet injectors (NFJIs) are a novel way to overcome common issues like pain, anxiety, and safety concerns. NFJIs work by delivering small amounts of liquid medication at high speed through the skin without the need for needles. Commercial NFJIs typically use gas or compressed springs to generate high-velocity jets, but their inability to modify input energy limits their use to limited volume and velocity ranges. More recently, they have added adjustable parameters based on skin-site characteristics, thickness, and intended delivery depth, greatly increasing their potential in dermatological applications. With an emphasis on needle-free intradermal injection (NFII) for targeted drug delivery, this review examines the changing role of NFJIs. Utilizing laser-generated cavitation, laser-induced jet injection is a noteworthy innovation that provides accurate, minimally invasive distribution. Significant benefits of this strategy include less tissue injury and improved control over jet characteristics. However, challenges such as safety, dose consistency, and regulatory approval persist. Integration with new technologies like customized medicine and digital health platforms presents NFJIs as revolutionary instruments in healthcare. Current restrictions should be addressed by ongoing research and technical advancements, opening the door for broad use in dermatological and medicinal applications.

Keywords

Needle Free Injection, Pressure, Spring system, Laser medium, Jet formation, Local anaesthesia, Intralesional injection, Dermal injection.

Introduction

Needle-free jet injectors (NFJIs) have been suggested as a feasible substitute for needle injections due to their ability to address the challenges related to conventional needles. All existing NFJIs operate on the same fundamental principle of propelling a small quantity of liquid (containing the medication) at high speed to penetrate the skin directly. Several commercial needle-free jet injectors utilize either a compressed spring or gas as a power source to drive a piston, which in turn expels the liquid through a narrow opening to create a rapid jet capable of piercing the skin. Despite their advantages over hypodermic needles, these commercial injectors are somewhat restrictive in their application. One limitation is the lack of adjustability in controlling the input energy required to expel the liquid. Consequently, most of these injectors are only able to produce jets within a narrow range of volume and velocity. The latest jet injectors have addressed many of these challenges by introducing customizable parameters based on skin-site characteristics, thickness, and the intended depth of medication delivery. This review concentrates on the dermatological application of jet injectors beyond vaccines and systemic drug delivery methods, specifically focusing on needle-free intradermal injection (NFII) of targeted drugs and medications. [1]

Principle of Laser-Induced Jet Injection Technology

Apparatus with compressed air cylinder and pressure intensifier involves a pressure gauge and PR valve that goes into two pneumatic lines, and one of which connects to the Schrader valve of the pressure intensifier through a small orifice and the other links with P-port of SMC Inc. (Tokyo, Japan) 3-port 2 way pilot operated pneumatic valve. [2].

Figure No. 1: Working mechanism of the developed needle-free jet injection system

MATERIALS AND METHODS

- Materials

Laser Medium:

Of all the components required to produce the energy necessary to create the jet, the laser source is considered the most significant. Common materials used for lasers in jet injection systems include:

Neodymium-doped Yttrium Aluminum Garnet (Nd:YAG):

This is one of the most frequently used laser medium and is especially common in pulsed machines operating at a wave length of 1.064 µm. Housing the high power circuit, it is designed with great durability in mind.

Alexandrite:

A base laser with the wave length of 700 to 800 nm; Although some specific medical applications can be utilized from this tunable laser. Diode Lasers: These lasers are portable and cheaper to produce especially in small devices since they are tunable in beam wavelength.[3]

- Materials Used On Nozzle and Delivery System Nozzle Materials:

The size of the nozzle orifice control the cross sectional shape of the microjet as well as its velocity and penetration depth. The material, therefore, of the nozzle must be suitable for the laser in use and the fluid being injected.

Glass:

Is translucent, and therefore easy to monitor; it is also chemically stable, therefore suitable to be used with a variety of fluids.

Silicon:

As the integrated fabrication technology is quite precise and can create very fine nozzle orifices for the micro-fluid systems, the multiple nozzle arrays are likely to be used in micro fabrication.

Stainless Steel:

Sometimes used for strong and solid devises but it can require special varnishes to protect it from heat produced by the laser.

Microchannel Materials:

In some laser induced systems, microchannels are incorporated into the body nozzle to act as the flow regulator to improve on the formation of the jet.

These are typically made of:

Polymers: Soft and flexible microchannels may be fabricated using PDMS (polydimethylsiloxane) or other biocompatible polymers.

Metals: In more advanced systems, microchannels can be fabricated from biocompatible material such as stainless steel or titanium.[4]

Pharmaceutical Fluids:

This paper reveals that the nature of the fluid injected affects the operation of laser-induced jet injection systems in a given system. The free surface properties, including viscosity and surface tension, affect cavitation and jet formation and must also have relevant characteristics.

The following fluids are commonly used: Water-based solutions (e.g., saline or phosphate-buffered saline): These are popular mainly for drug and vaccines’ delivery since they are safe and easy to use.

Hydrogel-based formulations: Employed for use in systems for administering drugs for long and short time release periods.

Vaccines and biological agents: These formulations have been prepared in a way that they do not alter or degrade under the conditions of exposure to the powerful lasers.

Additives and Stabilizers: Sometimes, the addition of stabilizers, surfactants or viscosity modifiers may be made so as to achieve the right rheological properties to allow proper formation of jets, as well as the stability of drugs during injection.[5]

Coatings for Protective and Biocompatible Materials:

Tissue Interaction Materials: Since the laser-induced jet goes through the skin or mucosal layers, the materials that cause low tissue irritation are relevant. These materials can include:

Collagen Scaffolds: To demonstrate the security of injection in simulated tissue, researchers employ ex vivo testing.

Biocompatible Coatings: It is also necessary to use some covering agents when performing the injection to avoid thermal damage of the tissues; the agents can be made from silicone and hydroxyapatite.

Shielding Materials: Laser safety barriers can also be applied in order to reduce the potential options for the lasers to leak towards the other parts of the body. These shields are typically made from: Such as plastic or metal for safety reasons because they are optically opaque.

- Sensors and Monitoring Materials High-Speed Cameras:

Cams with high-speed options along with silicon-based CCD or CMOS sensors are employed for capturing the jet formation process and real-time examination of the jet trajectory and velocity.

Pressure and Velocity Sensors:

Velocity of the jet is determined by piezoelectric sensors or laser Doppler anemometry systems are used often to maintain the fluid delivery velocity.

Mechanism Of Action Of Laser-Induced Jet Injections

Laser-induced jet injection is an innovative method for drug delivery that eliminates the need for needles. This technique utilizes laser energy to generate mechanical force, which is then used to propel a liquid jet at high speeds into the targeted tissue.

1. Laser Energy Absorption:

A pulsed laser beam is aimed towards a chamber filled with liquid or a solid-liquid boundary.

The target absorbs the laser energy, with potential enhancement through the use of photoabsorptive substances or dyes in the liquid.

This absorbed energy results in localized heating, causing swift phase transitions. [6]

2. Cavitation Bubble Formation:

The swift increase in temperature induces the formation of a vapor bubble, known as a cavitation bubble, within the liquid as a result of a change in phase. The characteristics and behavior of the bubble are influenced by the laser's settings, including energy density and pulse length, as well as the specific attributes of the liquid being used. [7]

3. Jet Formation:

The liquid is ejected in a concentrated microjet at speeds surpassing 100 m/s.

The design of the nozzle guarantees a thin and accurate jet that can effectively penetrate the outer skin layers without causing harm to neighbouring tissues. [8]

4. Jet-Tissue Interaction:

The high-velocity jet punctures the epidermis, establishing a tiny passage for medication administration.

The infused solution diffuses within the dermis, facilitating the absorption of the drug through the skin.[9]

5. Factors Influencing Mechanism:

- The laser characteristics include the wavelength, pulse energy, pulse duration, and repetition rate.

- The liquid properties to consider are viscosity, density, surface tension, and optical absorption coefficient.

- The nozzle design aspects encompass dimensions, shape, and material composition. In terms of the target tissue, factors such as skin elasticity, thickness, and hydration levels are important to take into account. [10]

- The latest jet injectors have addressed many of these challenges by introducing customizable parameters based on skin-site characteristics, thickness, and the intended depth of medication delivery. This review concentrates on the dermatological application of jet injectors beyond vaccines and systemic drug delivery methods, specifically focusing on needle-free intradermal injection (NFII) of targeted drugs and medications.[11]

Types Of Jet Injector

Except for immunisations and systemically absorbed medications such as insulin, NFII is a needle-free drug delivery method that utilises a rapid fluid stream to contact the skin and deliver a drug. A corticosteroid, an anaesthetic, onabotulinum toxin A (BoNT-ONA), bleomycin, 5-aminolevulinic acid (ALA), or any injectable material may be present in the fluid. There are two varieties of NFII injectors:

1. Jet injector with spring loading

2. Jet injector that runs on petrol

For a spring-loaded jet injector to work, a spring mechanism must be pulled back. The spring is released when the trigger is pulled, producing a drug jet stream that is used for drug delivery. For the subsequent administration, the activated spring load needs to be manually repainted. An air/gas cartridge that is attached to the pistol via a tubing system makes up a gas-powered jet injector. When the trigger is actuated, the piston is released, producing a drug jet stream. Both are suitable for intradermal, intramuscular, and subcutaneous administration.

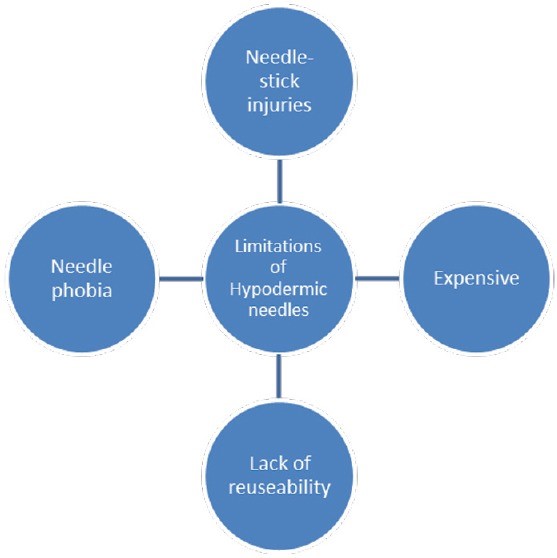

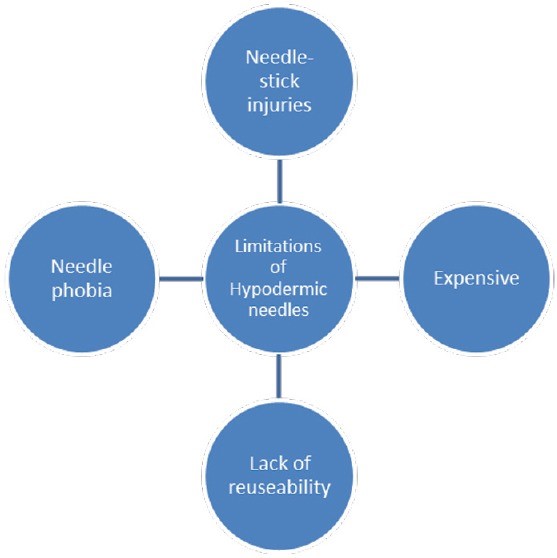

Figure No:2 Limitations of Hypodermic Needles

Classification Of Needle Free Injection Technology

- Based on the functioning

a. Spring Systems

b. Laser Powered

c. Systems powered by energy

i. Lorentz force

ii. Air-forced or gas-powered

iii. Waves of shock

2. Based On Type of Load

a. Powder

b. Liquid

c. Projectile

3. Based on the drug delivery technique

a. Nanopatches

b. Delivery was aided by sandpaper

c. Enabled Iontophoresis

d. Tiny needles

4. Based on the delivery site

a. Injectors inserted into the skin

b. Injectors that go into the muscle

c. Injectors that are subcutaneous

1.Based on the functioning:

a. Spring system:

It has been demonstrated that springs are a very efficient way to store energy and power NFIT devices. One of the simplest and most straightforward methods for NFITs is energy storage and additional transmittance through springs. Nonetheless, the spring's design must adhere to accepted practices, and storage conditions must be straightforward, or the will eventually "set," impairing the device's. The fundamental problem with the spring's design is that, in accordance with Hook's law, the force it provides will decrease proportionately to the distance over which the load has been applied.

b. Laser-powered:

The technology drives a very fine and precise stream of drug or medication with the appropriate amount of force using an erbium-doped yttrium garnet laser, the same laser used for laser resurfacing. The drug to be administered is held in place by an adapter that is integrated into the laser. Additionally, the apparatus has a water chamber that is used to drive the medication; however, the setup is such that the drug is separated from the driving fluid (water) with the assistance of source.

c. System powered by energy:

Commercial spring powered jet injectors are frequently noisy and occasionally painful, and they provide little to no control over the pressure that is applied to the drug during the injection. Energy in different forms can also be used to generate the force needed to propel the drug in order to have a penetrating.

i. The Lorentz force:

MIT researchers have developed an NFIT device that pushes a piston forward using Lorentz force, ejecting the drug at extremely high pressure and velocity (nearly equal to sound in air). The Lorentz force actuator, the device's primary component, makes the entire process easier.

ii. Air-forced or gas-powered:

Although gas-powered NFITs have more potential because compressed gas has a higher energy density than metal springs, gas as a power source will be less appropriate for reusable devices unless special arrangements, design changes, or component modifications can be made to ensure that the pressure is maintained and the spring is reset for each injection. Most gas-powered devices are either one-time use or require a gas cartridge replacement on a regular basis. Developing a gas spring that retains a certain percentage of the gas to function at the end of its shelf life is a significant challenge. Some gadgets employ gas as a basic spring, accelerating the piston with the gas that is stored. These devices are portable and compact. Any abrupt release of energy produces shock waves. These disruptions are capable of spreading through a medium because they contain energy. Using this energy at supersonic levels, researchers at the "Indian Institute of Science" (IISc) in Bengaluru have created a needless noninvasive drug delivery system.

- Based on the type of load:

- Powder:

The ability to create particles with enough density and accelerate them to a speed that is strong enough to penetrate the skin and in a quantity that reaches the therapeutic dose levels is essential for powder needle-free injection. The use of helium as a power source enabled this to be successful.

- Liquid:

NFIT is the original NFIT system variant, and it is still being developed by significant pharmaceutical companies. The ability of a liquid jet that is powerful enough to pierce the skin and the underlying fat layer without damaging the skin or the integrity of the drug molecule is the key to a successful injection using a needle-free system. Since the mechanics of liquid NFITs are so intricate, recent research has been done to fully comprehend the process.

- Depot/Projectile:

With sufficient mechanical strength, the drug is transformed into a long, thin depot that may convey a driving force to a pointed tip composed of either an inert material or the medication itself. This is a highly advanced version of the NFITs compared to the previous ones.

A depot typically takes the shape of a cylinder that is a few millimetres long and about 1 mm in diameter. Although the payload may be limited by this dimension, there is enough of it for many novel therapeutic proteins, antibodies, and other smaller molecules. When struck with the sharp-tipped punch, the depot can pierce the skin with a force of three to eight megatons.

3.Based on Drug Delivery Technique:

a. Nanopatches:

The use of an applicator to administer the medication through the skin is necessary for the operation of a nanopatch or microprojection. Since nano-patch projections cannot be seen with the naked eye, it is not expected that they will frighten people. When it comes to vaccines, drug delivery via nanopatches has proven to be very effective. The vaccine can reach the important immune cells beneath the skin's surface thanks to nanopatches, and the procedure is painless throughout.

b. Aided by sand paper:

To facilitate the entire drug delivery process, a 220 grit "sandpaper" type of agent is typically rubbed onto the skin to cause micro-derma abrasion, a phenomenon in which the skin's outermost layer is removed.

- Enabled Iontophoresis:

The skin's lipophilia prevents the entry of various salts and other substances. Several drug molecules are forced through the skin during iontophoresis using a very small electric current of about 0.5 mA/cm2. [25] This method uses two electrodes as patches to complete the circuit. One electrode serves as a drug reservoir and can be either positively or negatively charged, depending on the type of drug. On the body, the other electrode is positioned.

d. A Tiny needle:

As the name implies, micro-needle patches use thousands of tiny spikes that are each about 750mm long.

4.Depending on the delivery site:

a. An intradermal injector:

DNA-based vaccines, which are relatively new, have been delivered to the intradermal layer using these systems.

The drug is administered by the system at a very shallow depth, i.e., in between the skin layers.

b. An intramuscular injector:

One of the most advanced NFIT systems used to administer drugs intramuscularly. This system has the deepest drug delivery of all. The most effective use of NFIT devices for drug delivery has been in vaccination.

c. Subcutaneous Injector:

This system has been used to administer human growth hormones and other therapeutic proteins. The drug is applied to the adipose layer, which is situated just below the skin

Clinical Applications of NFJS Transdermal Drug Delivery Systems

NFJIs have shown efficacy in delivering drugs transdermally for the treatment of various dermatological conditions. This method allows for a precise and controlled administration of drugs into the skin, minimizing potential side effects.

- Local anesthesia using NFJs:

One application of NFJIs is in providing local anesthesia, also known as jet anesthesia, prior to procedures such as botulinum toxin injections for palmar hyperhidrosis. Studies have demonstrated the effectiveness of NFJIs in reducing pain and minimizing the risk of nerve or vessel injury during local anesthesia of the palms. Additionally, NFJIs have been found to be useful for performing digital blocks, with lower pain scores reported compared to traditional needle-based techniques.

- Intralesional corticosteroid injection:

Non-Forced Jet Injectors (NFJIs) present a viable option to corticosteroid needle injections as they can alleviate pain and ensure a uniform distribution of corticosteroids within intradermal lesions. By utilizing NFJIs, corticosteroids can be dispersed more evenly within intradermal lesions like alopecia areata (AA), as opposed to accumulating along the needle insertion path. However, there is a possibility of NFJI blockage by corticosteroid clusters during injection, which can be mitigated by agitating the triamcinolone suspension with a nozzle of larger diameter. Abell et al. Documented successful outcomes in treating alopecia areata (AA), granuloma annulare (GA), and necrobiosis lipoidica using triamcinolone injections via the Porto-jet needleless injector. Another study evaluated the effectiveness and safety of NFJI for corticosteroid matrix injections in psoriatic fingernails. While injecting corticosteroids into the nail matrix with a needle is a conventional approach for nail psoriasis, it often leads to significant pain that hinders treatment. Corticosteroid matrix injections with NFJIs resulted in a less painful and more effective treatment for psoriatic nails, as evidenced by a reduction in the Nail Psoriasis Severity Index (NAPSI) score.

- Intralesional bleomycin injection:

Intralesional administration of bleomycin has proven to be effective in the treatment of stubborn planar warts. Agius and colleagues demonstrated the success of bleomycin injection using needle-free jet injectors (NFJIs) in a cohort of 47 patients with 138 recalcitrant plantar warts that had not responded to 10 rounds of cryosurgery. Following one to five treatment sessions, there was an overall clearance rate (comprising complete and partial responses) of 89.9%. The investigators noted that NFJIs were particularly well-suited for penetrating thick skin on the extremities and could be easily utilized on contoured surfaces such as the sole of the foot. Moreover, bleomycin injections via NFJIs have exhibited efficacy in the treatment of keloids and hypertrophic scars in initial investigations. In a study involving 14 patients with these dermal conditions, successful outcomes were attained after two to six treatment sessions using lower doses of bleomycin (0.4 mL/cm2) compared to traditional needle injections (2 mL/cm2). The researchers concluded that the use of NFJIs facilitated a more uniform distribution of bleomycin within the lesions, resulting in favorable clinical responses despite the reduced volume of medication.

- Intralesional 5-aminolevulinic acid injection:

The efficacy of photodynamic therapy (PDT) utilizing 5-aminolevulinic acid (ALA) for anogenital warts has been established. However, achieving optimal penetration of ALA through topical application can be challenging, especially in cases of thick and extensive warts.

In a study by Li et al, the use of ALA injection via needle-free jet injection (NFJI) was compared to topical ALA application for treating condyloma acuminatum (CA). The NFJI group showed significantly higher complete response rates and lower recurrence rates. Additionally, the incubation time before irradiation was reduced to 1.5 hours with NFJI, compared to the conventional 3-hour incubation period with topical application.

It also utilized NFJI to inject 20% ALA before PDT for nodular basal cell carcinomas (BCCs), resulting in long-lasting complete remission with minimal side effects. Successful treatment of nodular BCC with ALA-PDT relies on adequate penetration of the photosensitizing agent into the lesion. The authors noted that NFJIs offer rapid and extensive drug distribution, enhancing treatment outcomes.[13]

Future Aspects of Laser Induced Jet Injections

Clinical Translation and Personalized Medicine

Adaptation to Diverse Patient Groups: Current LIJI systems could be optimized to the desired populations, eg paediatric, geriatric and patients with certain skin types. This analytical overview suggests that variation of jet velocities and fluid volumes as related to skin properties can potentially optimize treatment outcomes. Integration with Diagnostics: LIJI systems may graduate into devices with diagnostic functions like the measuring of skin impedance or the properties of the local tissue to set optimum injection parameters.

The development of Biologics and Vaccines Delivery

mRNA and Gene Therapy: Traditional shipping methods are not optimal for the delivery of vulnerable biologics, notably mRNA vaccines, and novel gene-editing tools such as CRISPR/Cas systems due to their delicate nature as well as variability in the dosages that need to be delivered.

Adjuvant-Free Vaccination: Through increasing antigen diffusion to dermal layers, LIJI might decrease or exclude dependence on adjuvants with reformulation of vaccines.

Materials and Integration as well as Reduction

Compact and Portable Systems: Improvements in laser size reduction and low power device integration could enable portable LIJI devices appropriate for use in rural or low resource environments.

Cost-Effective Components: The cost advantages of LIJI include reduction in expense for laser diode and disposable cartridge and making LIJI cheaper than usual injection techniques.

Application in Regenerative Medicine

Recent advanced researches have shown that culture growth systems has vital application in regenerative medicine.

Stem Cell Delivery: Such the non-invasive method could be useful to implant stem cells or growth factors only into the specific tissue areas to enhance the efficacy in the treatment of the skin injury and the tissue repairing process.

Advanced Cosmeceuticals: Other possibilities might include: dermatological applications where LIJI would allow the efficient deposition of anti-aging agents, peptides, or nucleic acids into the dermis. As a result of these factors, the regulatory force and market adoption have become significant concerns in the industry.

Standardization and Safety Protocols: Standardising the safety practices and requirements of LIJI across the world will help in acquiring necessary regulatory permissions to reach polymorphic diversification.

Market Expansion: LIJI, could be used in veterinary medicine, the treatment of chronic diseases through drug delivery and possibly cosmetic use all which could expand its market frontiers.

Combination Therapies

Synergistic Drug Delivery: Additional to LIJI, other technologies like microneedle arrays or electroporation might be combined to improve the delivery of multi-component therapeutics.

Controlled Release Systems: The introduction of LIJI into formulations for controlled release drugs could probably give a long-term therapeutic impact using the product in question just once.

Long-Term Research Directions

Optimization of Laser Parameters: Further investigation of the relationship between theoretical laser wavelength, pulse duration, and the interaction with the fluid will enhance the understanding of jet behaviour and repeatability.

Exploration of New Modalities: New features may be pulsed or patterned jets for selective activation of the tissue layers and for multi-component liquid applications.[14][15]

CONCLUSION

Laser-induced jet injection presents a promising paradigm shift in drug delivery, offering a needle-free approach with the potential to revolutionize various medical applications. By harnessing the power of laser-generated cavitation, this technology enables precise and controlled delivery of therapeutic substances with minimal invasiveness. While challenges such as safety considerations, dose consistency, and regulatory hurdles remain, ongoing research and technological advancements are continuously addressing these issues. The integration of laser-induced jet injection with emerging technologies like personalized medicine and digital health platforms holds immense potential for transforming healthcare delivery. As research progresses and clinical applications expand, laser-induced jet injection is poised to become an indispensable tool in modern medicine, offering improved patient outcomes and enhanced treatment options across a spectrum of therapeutic area.

ACKNOWLEDGEMENT

I would like to thank everyone who assisted me in completing my investigation on the Transforming Pharmaceutical Practices: Laser Induced Jet injection Technology. Their knowledge and help have been invaluable. I am appreciative of the resources provided by the library and my instructors, as well as the databases and research articles that improved my understanding of efficacy and advanced technology of needle free injections potential medical uses. Finally, I would want to thank my friends for their encouragement.

REFERENCES

- Schoppink J, Rivas DF. Jet injectors: Perspectives for small volume delivery with lasers. Advanced drug delivery reviews. 2022 Mar 1;182:114109.

- Trimzi MA, Ham YB. A needle-free jet injection system for controlled release and repeated biopharmaceutical delivery. Pharmaceutics. 2021 Oct 22;13(11):1770.

- Tagawa Y, Oudalov N, El Ghalbzouri A, Sun C, Lohse D. Needle-free injection into skin and soft matter with highly focused microjets. Lab on a Chip. 2013;13(7):1357-63.

- Cilip CM, Rosenbury SB, Giglio N, Hutchens TC, Schweinsberger GR, Kerr D, Latimer C, Nau WH, Fried NM. Infrared laser thermal fusion of blood vessels: preliminary ex vivo tissue studies. Journal of biomedical optics. 2013 May 1;18(5):058001-.

- Veeranarayanan S, Maekawa T. External stimulus responsive inorganic nanomaterials for cancer theranostics. Advanced Drug Delivery Reviews. 2019 Jan 1;138:18-40.

- Fossum ER. CMOS image sensors: Electronic camera-on-a-chip. IEEE transactions on electron devices. 1997 Oct;44(10):1689-98.

- Eibeck A, Shaocong Z, Mei Qi L, Kraft M. Research data supporting" A Simple and Efficient Approach to Unsupervised Instance Matching and its Application to Linked Data of Power Plants".

- Albo A, Cytermann C, Bahir G, Fekete D. Utilizing the interface adsorption of nitrogen for the growth of high-quality GaInAsN/GaAs quantum wells by metal organic chemical vapor deposition for near infrared applications. Applied Physics Letters. 2010 Apr 5;96(14).

- Zaszczy?ska A, Moczulska-Heljak M, Gradys A, Sajkiewicz P. Advances in 3D printing for tissue engineering. Materials. 2021 Jun 8;14(12):3149.

- Van Eerdenbrugh B, Van den Mooter G, Augustijns P. Top-down production of drug nanocrystals: nanosuspension stabilization, miniaturization and transformation into solid products. International journal of pharmaceutics. 2008 Nov 19;364(1):64-75.

- Sasaki GH, Travis HM, Tucker B. Fractional CO2 laser resurfacing of photoaged facial and non-facial skin: histologic and clinical results and side effects. Journal of Cosmetic and Laser Therapy. 2009 Jan 1;11(4):190-201.

- Ravi AD, Sadhna D, Nagpaal D, Chawla L. Needle free injection technology: A complete insight. International journal of pharmaceutical investigation. 2015 Oct;5(4):192.

- Han HS, Hong JY, Kwon TR, Lee SE, Yoo KH, Choi SY, Kim BJ. Mechanism and clinical applications of needle?free injectors in dermatology: literature review. Journal of Cosmetic Dermatology. 2021 Dec;20(12):3793-801.

- Sahin U, Karikó K, Türeci Ö. mRNA-based therapeutics—developing a new class of drugs. Nature reviews Drug discovery. 2014 Oct;13(10):759-80.

- Keshavarz R, Olsen S, Almeida B. Using biomaterials to improve mesenchymal stem cell therapies for chronic, nonhealing wounds. Bioengineering & Translational Medicine. 2024 Jan;9(1):e10598

Karuna. Earni*

Karuna. Earni*

Vasanthi. Kadagalla

Vasanthi. Kadagalla

10.5281/zenodo.14671500

10.5281/zenodo.14671500