Abstract

This project investigates biodiesel production using the fresh algae collected from the pond and washed with fresh water 5-6 times. Then the algae is identified by microscopic examination and the species was identified as Chaetophorales. The algae were ground with n-hexane, methanol, an n caustic soda and incubated in the mixture for 24 hrs. After the algal biomass was removed from the separating funnel and collected the oil, the oil was burnt as a confirmation i.e. biodiesel. The TLC test confirmed the extracted oil as biodiesel. In the present work, the key concentration is directed towards producing renewable biofuels from algal biomass. This research highlights the potential of algae as a sustainable feedstock for biodiesel production, paving the way for scalable applications that can significantly reduce reliance on fossil fuels while promoting ecological balance. Biodiesel is more environmentally friendly than diesel, reducing greenhouse gas emissions by up to 86%. Biodiesel is also non-toxic and biodegradable.

Keywords

Biodiesel, Chaetophorales, TLC, fossil fuels, and Non-toxic.

Introduction

Biodiesel has gained much attention in recent years due to its eco-friendly nature, non-toxic characteristics, biodegradability, and lower net carbon cycle compared to conventional diesel fuels. Algae can be converted into various types of energy for transportation, including biodiesel, jet fuel, electric power, and ethanol. The potential advantages of algae-based biofuel over other biofuel pathways include higher biomass yields per acre of cultivation, little to no competition for arable land, use of a wide variety of water sources, the opportunity to reuse carbon dioxide from stationary sources, and the potential to produce “drop-in” ready-to-use fuels. Biodiesel production from renewable sources is widely considered to be one of the most sustainable alternatives to petroleum-sourced fuels and a viable means for environmental and economic sustainability [1]. It was reported that algae were one of the best sources of biodiesel. In fact, algae are the highest-yielding feedstock for biodiesel. It can produce up to 250 times the amount of oil per acre as soybeans. In fact, producing biodiesel from algae may be only the way to produce enough automotive fuel to replace current gasoline usage. Algae can produce 7 to 31 times greater oil than palm oil. It is very simple to extract oil from algae. The best algae for biodiesel would be microalgae. Microalgae are an organism capable of photosynthesis that is less than 2 mm in diameter. Macroalgae, like seaweed, is not as widely used in the production of biodiesel. Microalgae has much more oil than macroalgae and it is much faster and easier to grow [2]. Microalgae can provide several different types of renewable biofuels. These include methane produced by anaerobic digestion of the algal biomass biodiesel derived from microalgal oil and photobiologically produced biohydrogen. The idea of using microalgae as a source of fuel is not new but it is now being taken seriously because of the escalating price of petroleum and, more significantly, the emerging concern about global warming that is associated with burning fossil fuels. Microalgae are currently being promoted as an ideal third generation biofuel feedstock because of their rapid growth rate, CO2 fixation ability and high production capacity of lipids; they also do not compete with food or feed crops, and can be produced on non-arable land. Microalgae have broad bioenergy potential as they can be used to produce liquid transportation and heating fuels, such as biodiesel and bioethanol [3].

The use of energy sources has reached the level that the whole world is relying on it. Being the major source of energy, fuels are considered the most important. The fear of diminishing the available sources of thirst towards biofuel production has increased during the last decades. Considering the food problems, algae gain the most attention to be used as biofuel producers. The use of crop and food-producing plants will never be the best fit into the priorities for biofuel production as they will disturb the food needs. The algae are now becoming the main source of biofuel production in the world. They are considered the safer, non-competitive, and rapidly growing organisms among those that could be used for biodiesel production. They can grow without much care for waste nutrients and are considered the better source of biodiesel production as other sources can cause food problems as they mainly include those plants that are used for food [4].?

Methodology

Collection of samples

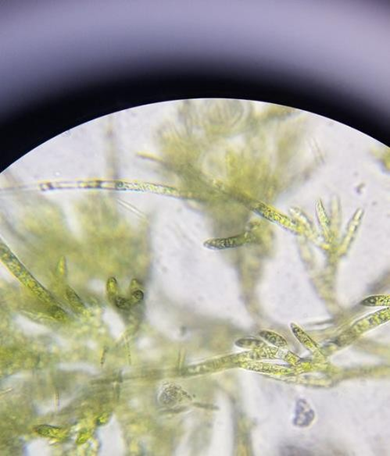

A collection of algae was carried out. Then the algae were brought to the laboratory in a closed container. Later the algae were rinsed in fresh water.

Fig.1.Freshly collected algae from the pond

Identification of algae

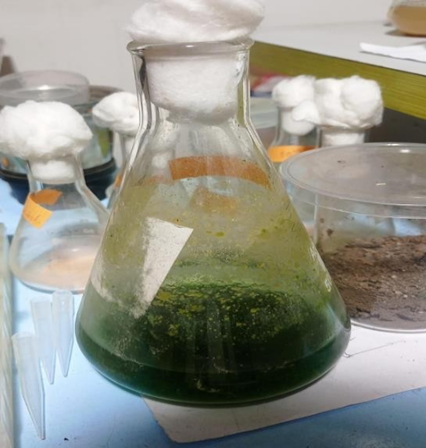

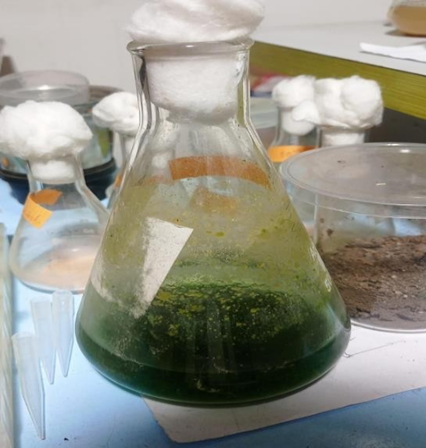

A sample of algae collected from the ponds underwent microscopic examination for identification purposes. Species were identified according to their morphological characters.

Fig.2.Algae under the microscope

Extraction of oil

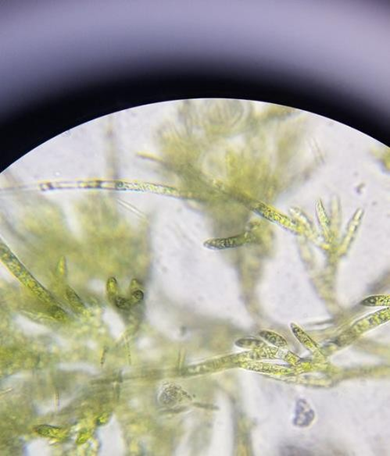

Algae was grounded with motor and pestle as much as possible. The grounded algae were dried for 20 min to release water. Ethanol, n-hexane, and casting soda were mixed with the grounded algae to extract oil. Then keep the mixture for 24 hrs for settling.

Separation and production of biodiesel

After 24 hrs the sample is transferred from the conical flask to the separating funnel. Algal biomass was removed from the separating funnel and the oil(biodiesel)into a storage bottle.

Detection Confirmation of biodiesel

The uppermost layer of the oil(biodiesel) is confirmed as biodiesel by the TLC test. With the help of solvent, mixtures of solution hexane, ethyl acetate, and acetic acid.

TLC Plate preparation:

1. Take 3gm of silica powder in a clean and dry beaker, and add 0.3g of CaSo4(Calcium sulfate) into 10ml of D/w for proper mixing. Take a sterile clean glass slide and add the heated sample to the glass slide uniformly.

2. Heat it in a hot air oven at 50°C until it gets solidified.

3. Approximately 5-6 narrow drops of biodiesel were placed in the TLC plate.

4. Dry overall spot placed in the TLC plate in saturated glass slide containing 2cm below solvent layer.

5. RF value calculated for each spot.

Solvent preparation: Take a solvent of 9 ml n-hexane, 1 ml ethyl acetate, and 0.1 ml of acetic acid this solution here was used as a solvent for the TLC test.

Results

Extraction of oil:

Biodiesel took about 5 whole days to extract the oil from the algal biomass.

Fig.1. Sample kept after adding n-hexane, methanol and caustic soda

Separation of the biodiesel:

Algal biomass was removed from the separating funnel and collected the oil(biodiesel)into a storage bottle.

Fig.2.Image of oil(biodiesel) when burnt

Detection of biodiesel:

The uppermost layer of the oil(biodiesel) was confirmed as biodiesel by TLC test. With the help of solvent, mixtures of solution hexane, ethyl acetate, and acetic acid. The solvent of TLC which was used for the identification binds with all the biodiesel and glowed under the UV the binding is irrespective of oil composition.

Fig.3. Detection of biodiesel

DISCUSSION

In this study, algae were selected for biodiesel production because their cell wall are rich in lipids and they are also fast-growing microorganisms that can produce significant amounts of oil therefore making them suitable for biodiesel production. Biodiesel from algae is a sustainable alternative to fossil fuels. Algae were collected from local ponds, the algae were processed and identified by microscopic examination and the species was identified as Chaetophorales according to their habitat and morphology [5-6]. The algae were ground with n-hexane, methanol, and caustic soda and incubated in the mixture for 24 hrs. After the algal biomass was removed from the separating funnel and collected the oil, the oil was burnt as a confirmation i.e. biodiesel. The TLC test confirmed the extracted oil as biodiesel. In a research paper by Knothe and Steidley, it was reported that biodiesel has a better lubricity than petrol-diesel hydrocarbons, because of the polarity that is introduced with the presence of oxygen atoms which is lacking in petrol-diesel. Lubricity it was reported to improve with the chain length and the presence of double bonds. One major technical advantage of biodiesel over petrol-diesel is lubricity [7].

CONCLUSION

Algae are an economical choice for biodiesel production, because of their availability and low cost. This project proves that biodiesel can be produced from algae. In this way, algae can be used as renewable energy. Considerable amounts of biodiesel can be produced from algae. Biomass after oil extraction may be used for livestock, ethanol production, and also in paper making. Continuous use of petroleum-sourced fuels is now widely recognized as unsustainable because of depleting supplies and the contribution of these fuels to the accumulation of carbon dioxide in the environment. From the present study, it can be concluded that algal biomass is a more beneficial raw material than agro-based raw materials for biodiesel production as it is available abundantly in freshwater as well as marine eco-system and more importantly it is renewable. Algae are an economical choice for biodiesel production, because of their availability and environmentally friendly properties

REFERENCES

- Ajala, E. O., Ajala, M. A., Akinpelu, G. S., & Akubude, V. C. (2021). Cultivation and processing of microalgae for its sustainability as a feedstock for biodiesel production. Nigerian Journal of Technological Development, 18(4), 322-343.

- Chintagunta, A. D., Zuccaro, G., Kumar, M., Kumar, S. J., Garlapati, V. K., Postemsky, P. D., & Simal- Gandara, J. (2021). Biodiesel production from lignocellulosic biomass using oleaginous microbes: prospects for biofuel production. Frontiers in Microbiology, 12, 658284.

- Zulqarnain, Mohd Yusoff, M. H., Ayoub, M., Ramzan, N., Nazir, M. H., Zahid, I., & Butt, T. A. (2021). Overview of feedstocks for sustainable biodiesel production and implementation of biodiesel program in Pakistan. ACS omega, 6(29), 19099-19114.

- Brennan L, Owende P.(2019) Biofuels from microalgae--A review of technologies for production, processing, and extractions of biofuels and co-products. Renewable and Sustainable Energy Reviews; 14:557-577.

- Bhardwaj, N., Agrawal, K., & Verma, P. (2020). Algal biofuels: an economic and effective alternative to fossil fuels. Microbial strategies for techno-economic biofuel production, 207-227.

- Deora, P. S., Verma, Y., Muhal, R. A., Goswami, C., & Singh, T. (2022). Biofuels: An alternative to conventional fuel and energy source. Materials Today: Proceedings, 48, 1178-1184.

- Jalilian, N., Najafpour, G. D., & Khajouei, M. (2020). Macro and micro algae in pollution control and biofuel production–a review. Chem Bio Eng Reviews, 7(1), 18-33.

- Knothe, G., & Steidley, K. R. (2019). Kinematic viscosity of biodiesel fuel components and related compounds. Influence of compound structure and comparison to petrol diesel fuel components. Fuel, 84(9), 1059-1065.

- Saad, M. G., Dosoky, N. S., Zoromba, M. S., & Shafik, H. M. (2019). Algal biofuels: current status and key challenges. Energies, 12(10), 1920.

- Tomar, S., Singh, H., Anand, K., & Rai, P. K. (2021). Biodiesel Production From Algae: Principles And Processes.

- Zhu, S., Xu, J., Adhikari, B., Lv, W., & Chen, H. (2023). Nostoc sphaeroides cyanobacteria: a review of its nutritional characteristics and processing technologies. Critical Reviews in Food Science and Nutrition, 63(27), 8975-8991

Gayatri Aghadte*

Gayatri Aghadte*

Vishal Lolge

Vishal Lolge

10.5281/zenodo.14263941

10.5281/zenodo.14263941