Abstract

This study presents the formulation of herbal lozenges using a heating and congealing technique. A thorough literature review informed the selection of excipients, which included Agar, Acacia, peppermint oil, citric acid, glycerin, PEG 1000, and PEG 8000. The lozenges were evaluated for weight variation, hardness, thickness, friability, disintegration time, and drug content, with all parameters meeting standard limits. Among the formulations, F6 demonstrated the highest drug content at 99.35%. The study concluded that the herbal lozenges, particularly those incorporating agar and acacia, are a promising therapeutic option for treating mouth and throat infections and enhancing immunity in patients. Stability studies were also conducted to ensure the formulation's viability.

Keywords

Lozenges, Herbal, Banana, Durva Grass.

Introduction

Solid dosage forms are highly favored for oral drug delivery due to their ease of administration, accurate dosage, and patient compliance. Tablets, in particular, are widely accepted because they allow for self-medication and help in avoiding pain. Many patients face challenges when it comes to swallowing conventional tablet dosage forms, especially when water is not readily available. Dispersible tablet delivery systems offer a solution with their fast disintegration, quick dissolving, rapid release, and improved patient compliance. This difficulty in swallowing, known as dysphagia, affects people of all age groups, particularly the elderly and pediatrics, due to physiological changes associated with these groups. In certain cases, individuals facing challenges with traditional oral medications include those with mental health issues, uncooperative behavior, and patients dealing with symptoms like nausea, motion sickness, sudden allergic reactions, or frequent coughing. Additionally, the absence of water can make it tough to consume conventional products. These difficulties have driven the creation of a new type of solid oral medication. As a result, there is a growing need for appealing formulations that effectively mask taste. When it comes to lozenges, they can contain a variety of drugs such as pain relievers, anesthetics, antimicrobials, antiseptics, cough suppressants, aromatic compounds, astringents, corticosteroids, decongestants, and soothing agents. Sore throats, mouth sores, and other irritations in the mouth and throat are common issues that can be quite painful. While there are many pharmaceutical options available, both over-the-counter and prescription, for treating this pain, it can be challenging to administer these drugs to patients who are unwilling or unable to take traditional oral medications. For instance, both children and adults might struggle to swallow tablets or capsules.

PLANT PROFILE:

-

- Plantain Banana:

- Name: Plantain.

- Synonyms: plantago, Fleawort, Musa paradisiaca.n, Goose grass, plantain Tree.n, Banana.n,

- Biological source: Musa paradisiaca.

- Family: plantaginacea.

-

- Taxonomical Classification:

- Kingdom: Plantae.

- Division: Magnoliophyta

- Class: Liliopsida

- Order: Zingiberales

- Family: Plantaginaceae

- Genus: Musa

- Species: Musa paradisiaca

-

- Vernacular Names Of Plantain:

|

Tamil

|

Vazhai

|

|

French

|

Bananier

|

|

German

|

Banane

|

|

English

|

Banana

|

|

Sanskrit

|

Kadali

|

|

Hindi

|

Kela

|

|

Urudu

|

Boana

|

|

Marathi

|

Kela

|

|

Kannada

|

Baale

|

|

Gujarat

|

Kelphool

|

|

Malayalam

|

Vazha

|

Table: 1 Vernacular Names Of Plantain

-

-

- Chemical Constituents:

The skin contained a higher concentration of cellulose (10%) and hemicellulose (13%) compared to the pulp, which only had 1.4?llulose and 1.3% hemicellulose. Additionally, the pulp protein was notably abundant in arginine, aspartic acid, and glutamic acid. Methionine was present in the lowest amount, while tryptophan and cystine were conspicuously absent.

-

-

- Uses:

To address dysentery, ulcers, bronchitis, and various other health issues, this treatment offers a range of benefits, including hypolipidemic, anti-diabetic, antioxidant, antimicrobial, anti-diarrheal, hepatoprotective, nephroprotective, and wound healing properties.

Figures: 1 Plantain Banana

-

- Durva Grass:

Name: Durva grass

Synonyms: Bermuda grass, Dog’s tooth grass, Devil’s grass, Indian doab, scutch grass, Bahama grass, couch grass, Dhub grass.

Biological source: Durva consists of dried whole plant of Cynodon dactylon Linn.

Family: Poaceae

2.2.1. Taxonomical Classification:

- Kingdom: Plantae

- Division: Magneliophyta

- Class: Liliopsida

- Order: Cyperales

- Family: Poaceae

- Genus: Cynodon

- Species: Cynodon Dactylon

2.2.2. Vernacular Names In India:

|

Sanskrit

|

Bhargavi, doorway, granthi, sveta

|

|

Hindi

|

Doorva, Doob

|

|

Tamil

|

Arugu, Arugmpull

|

|

Bengali

|

Durba

|

|

Kannada

|

Ambate-hull, Garikae

|

|

Malayalam

|

Karuka-pulli

|

|

Marathi

|

Doorva, haryali

|

|

Punjabi

|

Dub, kabbar, Talla

|

|

Telugu

|

Garka, Gerkie, Haryali

|

|

Pushtu

|

Kabal

|

|

Urdu

|

Ghass

|

Table: 2 Vernacular Names Of Durva Grass

2.2.3. Chemical Constituents:

The chemical constituents present in Cynodon dactylon are:

- Alkaloids: Ergonovine, Ergonovine.

- Phytosterols: Beta sitosterol,

- Carotenoids: Beta carotene,

- Fatty acids: Palmitic acid,

- Phenolic acids: P- coumaric acid, vanillic acid, P-hydroxyphenyl acetic acids.

- Others: Arundoin, friedelin, selenium, cyanogenic hyperoside.

- Vitamins: vitamin C

-

- Uses:

To address Treats acidity, Boost immunity, Controls sugar, Polycystic Ovarian Syndrome and menstrual problems, Obesity, Purifies blood, Cures eye infection and stops nose bleeding, Fertility and Skin diseases.

Figures: 2 Durva Grass

MATERIALS AND METHODS:

3.1. Authentication Certificate:

The plant material collected was identified and authenticated by by Dr. KN Sunil kumar Research officer HOD Department of pharmacognosy, Dr. P.Elankani Research officer ( Siddha ), Sci III-Incharge, SIDDHA CENTRAL RESEARCH INSTITUTE (Central Council for Research in Siddha, Chennai, Ministry of AYUSH, Government of India) Anna Govt. Hospital Campus, Arumbakkam, Chennai – 600106,

Certified that the samples submitted by A. Abdullah, A. Afroze, L. Akash, R. Aishwarya and V. Anitha, B Pharm, Aadhi Bhagawan College of Pharmacy, Rantham, Tiruvannamalai village were identified as:

- Form No: PCOG002-ACF

- Code: C06092402D Cynodon dactylon (L.) Pers.1, M06092403P Musa × paradisiaca L.2

- Part: Whole plant, Pericarp.

- Date: 10.09.2024

- Extraction:

3.2.1. Extraction From Plantain Banana:

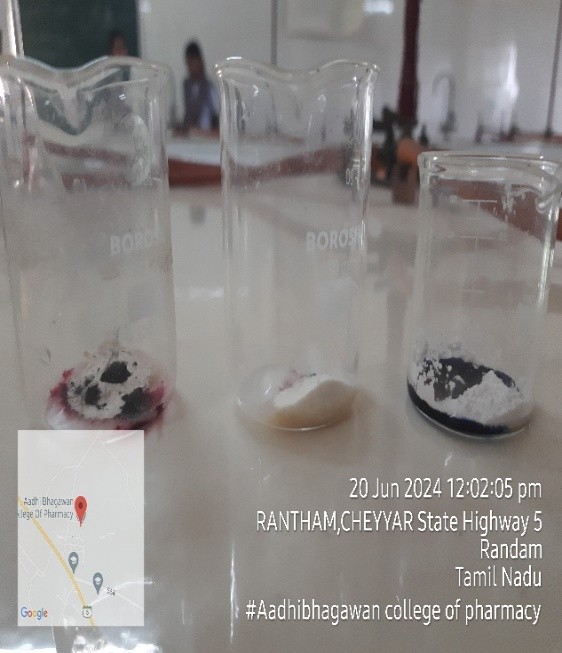

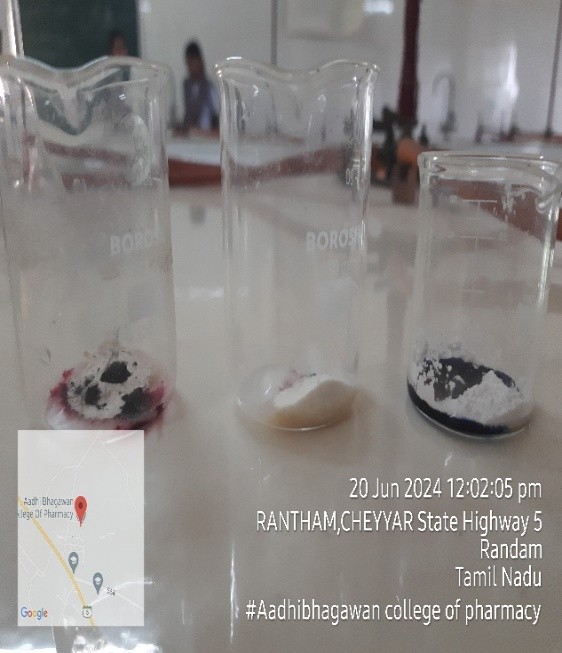

The peel of the plantain banana was collected and dried for some time. Then the peel is cut into small pieces as appropriate for the efficient extraction of chemical constituents. In the process of extraction the cutted pieces of banana peel is placed in stoppered container with the ethanol as a solvent and allowed to stand at room temperature for a period of at least 3 days with frequent agitation untill the soluble matter has dissolved. The mixture is then strained, the Marc is pressed, and the combined liquids are clarified by filtration after standing.

3.2.2. Extraction From Cynodon Dactylon:

The method of extraction is Maceration. The durva grass is washed with water. Then cut into small pieces as appropriate. In the process of Maceration the cutted pieces of durva grass is placed in a stoppered container with the ethanol as a solvent and allowed to stand at room temperature for a period of at least 3 days with frequent agitation untill the soluble matter has dissolved. The mixture is then strained and the Marc is pressed, the combined liquids are clarified by filtration after standing.

Figures: 3 Extraction

3.3. Phytochemical Evaluation:

- Test For Alkaloids

- Test For Phenol

- Tests For Flavonoids

- Test For Glycosides

- Test for Fats and Oils

- Test For Polyphenols

- Test For Tannins

- Test For Amino acid

- Test For Carbohydrate

- Test For Terpenoids

- Test For Saponins

3.4. Formulation Of Herbal Lozenges:

Composition For 40 Herbal Lozenges

|

S.NO

|

INGREDIENTS

|

F1

|

F2

|

F3

|

F4

|

F5

|

F6

|

|

1

|

EXTRACT

|

5ml

|

5ml

|

5ml

|

5ml

|

5ml

|

5ml

|

|

2

|

GLYCERIN

|

70ml

|

75ml

|

-

|

-

|

-

|

-

|

|

3

|

PEG 1000

|

-

|

-

|

70ml

|

75ml

|

-

|

-

|

|

4

|

PEG 8000

|

-

|

-

|

-

|

-

|

65ml

|

70ml

|

|

5

|

AGAR

|

17.5gm

|

-

|

18gm

|

-

|

18.5gm

|

-

|

|

6

|

ACACIA

|

-

|

18gm

|

-

|

18.5gm

|

-

|

19gm

|

|

7

|

CITRIC ACID

|

0.4gm

|

0.4gm

|

0.4gm

|

0.4gm

|

0.4gm

|

0.4gm

|

|

8

|

WATER

|

12ml

|

12ml

|

12ml

|

12ml

|

12ml

|

12ml

|

|

9

|

PEPPERMINT OIL

|

3 to 4 drop

|

3 to 4 drop

|

3 to 4 drop

|

3 to 4 drop

|

3 to 4 drop

|

3 to 4 drop

|

|

10

|

COLOR

|

Q.S

|

Q.S

|

Q.S

|

Q.S

|

Q.S

|

Q.S

|

Table: 3 Composition Of Herbal Lozenges

PROCEDURE:

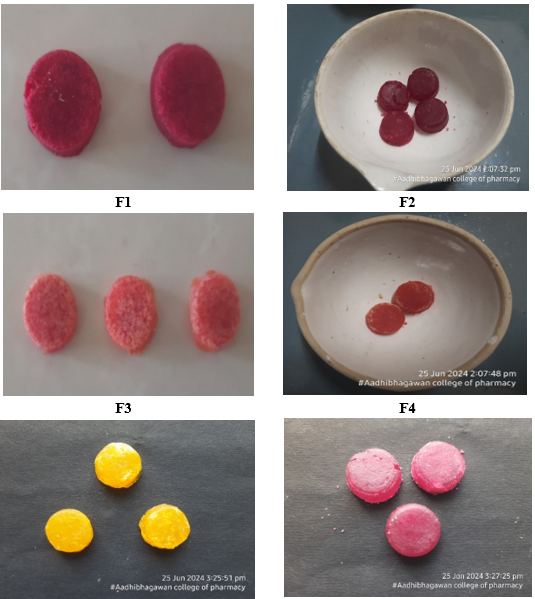

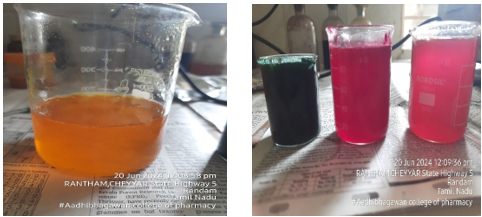

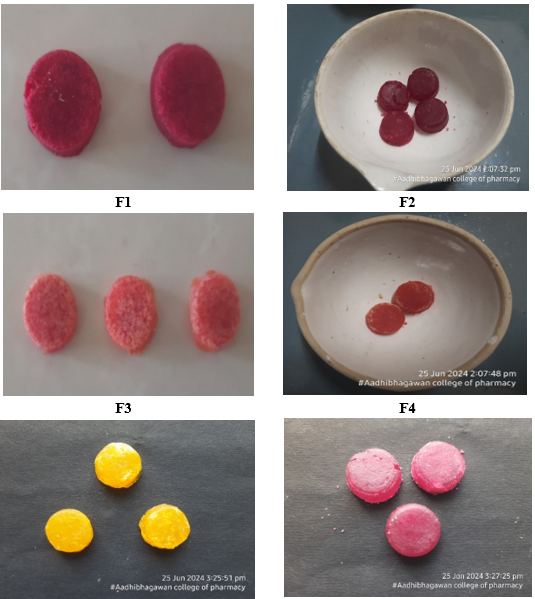

Herbal lozenges were prepared by heating and congealing technique. base was prepared by dissolving required amounts of water while heating it and stirring continuously for 60 min at the temperature of 90?C. polymers was added to the base to prevent crystallization of base, and the base was heated and stirred continuously till a plastic mass was obtained. The temperature was brought down to 40?C and to the plastic mass, drug dispersed in base, preservative, colour and flavor were added and the material was stirred for 20min. Then the mixture was poured in to desire molds and air dried for 1hr.

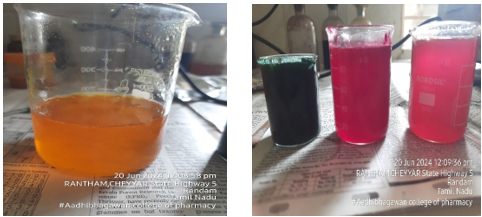

Figures: 4 Extract With Excipients

Figures: 5 Preparation Image

Figures: 6 Herbal Lozenges

3.5. Evaluation Of Herbal Lozenges:

3.5.1. Physical Parameter:

The general appearance of a lozenges including size, shape, colour, odour, taste having should be observed. It is must to have a good appearance for consumer acceptance. Physical changes may occur during storage, which can be determined PH using PH meter apparatus.

3.5.2. Thickness:

The thickness and diameter of the formulated lozenges were measured by using Vernier callipers.

3.5.3. Diameter:

The thickness and diameter of lozenges were determined using vernier callipers. [Three lozenges from each batch were used and average values were calculated. The extent to which the diameter of the lozenges deviated from ± 5 % of the standard value.

3.5.4. Weight Variation:

The formulated lozenges were tested for weight uniformity. 10 lozenges were collectively and individually. From the collective weight, average weight was calculated. Each lozenges weight was then compared with average weight to ascertain whether it is with in permissible limits or not.

3.5.5. Hardness:

The lozenges crushing strength, which is the force required to break the lozenges by compression in the diametric direction was measured in triplicate using Pfizer tablet hardness tester or Monsanto hardness tester.

3.5.6. Friability:

The Roche friability test apparatus was used to determine the friability of the lozenges. 5 pre-weighed lozenges were placed in the apparatus, which was subjected to 100 revolutions. Then the lozenges were reweighed.

3.5.7. Moisture Content:

The sample was weighed and crushed in a mortar. From this, one gram of the sample was weighed and placed in desiccators for 24 hours. After 24 hours the sample is weighed. The moisture content is determined by the abstracting the final weight from initial weight of lozenges.

3.5.8. Disintegration Test:

Disintegration study performed by disintegration apparatus. Put one lozenges into each tube suspend the assembly in the beaker containing pH 7.1 phosphate buffer and operate without the discs 30 min. Remove the assembly from the liquid. The Herbal lozenges pass.

3.5.9. Drug Content:

Drug content is done by taking an appropriate number of lozenges being crushed and dissolved in a suitable solvent and the absorbance of the solution is measured spectrophotometrically. Weighed 10 gm of each lozenges formulation were transferred in 250 ml of the volumetric flask containing 20 ml of Phosphate buffer 7.1 and stirred. The volume was made up to 100 ml and filtered. 1 ml of the above solution was further diluted to 10 ml with Phosphate buffer 7.1 and again 1 ml of the above solution was further diluted to 10 ml with Phosphate buffer 7.1. The absorbance of the solution was measured spectrophotometrically at 224 nm. Drug content was calculated by the following formula

Drug content=absorbanceslope × Dilution factor ×11000

× Dilution factor ×11000

3.5.10. Sensory Evaluation:

Sensory evaluation of lozenges was done, following parameters were considered like color, taste, flavor, consistency and overall acceptability. On the basis of this evaluation following results came out.

3.5.11. Stability studies:

As per ICH guidelines stability studies were conducted for selected formulation and it was observed that there was no significant change in the physical appearance and in the physicochemical characteristics of selected formulation.

3.5.12. Feed Back Data:

The data of prepared lozenges without Drug in Healthy Human Volunteers to collect the feed back information.

Figures: 7 Evaluation Of Herbal Lozenges

RESULTS AND DISCUSSION:

4.1. Preliminary Phytochemical Screening:

|

S.NO

|

CONSTITUENTS

|

DURVA GRASS

|

PLANTAIN BANANA

|

|

1

|

Alkaloids

|

Present

|

Present

|

|

2.

|

Carbohydrates

|

Absent

|

Present

|

|

3.

|

Protein

|

Absent

|

Present

|

|

4.

|

Terpenoids

|

Present

|

Present

|

|

5.

|

Phenol

|

Present

|

Present

|

|

6.

|

Tannins

|

Present

|

Present

|

|

7.

|

Flavonoids

|

Present

|

Present

|

|

8.

|

Glycosides

|

Present

|

Present

|

|

9.

|

Saponins

|

Absent

|

Absent

|

|

10.

|

Phytosterols

|

Absent

|

Absent

|

Table: 4 Preliminary Phytochemical Screening

4.2 Physical Parameter:

|

BATCH NO

|

COLOUR

|

ODOUR

|

TASTE

|

SHAPE

|

|

F1

|

Red

|

Aromatic

|

Aromatic

|

Round

|

|

F2

|

Dark Red

|

Aromatic

|

Aromatic

|

Round

|

|

F3

|

Orange

|

Aromatic

|

Aromatic

|

Round

|

|

F4

|

Dark Orange

|

Aromatic

|

Aromatic

|

Round

|

|

F5

|

Yellow

|

Aromatic

|

Aromatic

|

Round

|

|

F6

|

Pink

|

Aromatic

|

Aromatic

|

Round

|

Table: 5 Physical Parameter

4.3. Physical Parameter:

|

BATCH NO

|

PH

|

WEIGHT VARIATION

(gm)

|

THICKNESS

(mm)

|

HARDNESS (Kg/Cm2)

|

|

F1

|

7.2

|

2.06±0.06

|

6.3±0.2

|

10.8±0.7

|

|

F2

|

7.2

|

2.16±0.03

|

6.3±0.1

|

10.9±0.1

|

|

F3

|

7.1

|

2.31±0.04

|

6.4±0.2

|

9.3±0.8

|

|

F4

|

7.5

|

2.44±0.10

|

6.4±0.3

|

9.8±0.3

|

|

F5

|

7.5

|

2.78±0.02

|

6.5±0.1

|

9.2±0.2

|

|

F6

|

7.4

|

2.95±0.05

|

6.5±0.2

|

10.9±0.2

|

Table: 6 Physical Parameter

4.4. Evaluation Of Herbal Lozenges:

|

BATCH NO

|

FRIABILITY %

|

MOISTURE CONTANT %

|

DISINTEGRATION TEST (min)

|

DRUG CONTENT %

|

|

F1

|

0.78±0.04

|

0.9

|

16

|

94.32±0.4

|

|

F2

|

0.80±0.07

|

1.0

|

17

|

93.22±0.3

|

|

F3

|

0.38±0.05

|

1.1

|

18

|

91.65±0.2

|

|

F4

|

0.65±0.13

|

0.9

|

19

|

92.44±0.2

|

|

F5

|

0.76±0.05

|

0.8

|

21

|

95.31±0.3

|

|

F6

|

0.35±0.06

|

0.8

|

20

|

99.35±0.6

|

Table: 7 Evaluation Of Herbal Lozenges

4.5. Sensory Evaluation:

|

S.NO

|

PARAMETER

|

F1

|

F2

|

F3

|

F4

|

F5

|

F6

|

|

1

|

COLOR

|

9

|

9

|

8

|

8

|

9

|

10

|

|

2

|

TASTE

|

8

|

9

|

8

|

7

|

9

|

9

|

|

3

|

FLAVOUR

|

8

|

9

|

8

|

7

|

9

|

10

|

|

4

|

SHAPE

|

8

|

9

|

8

|

7

|

9

|

10

|

|

5

|

CONSISTENCY

|

8

|

9

|

8

|

8

|

9

|

9

|

1: extremely dislike, 2: strongly dislike, 3: moderate dislike, 4: slight dislike, 5: neutral,

6: slight like, 7: moderate like, 8: strongly like, 9: extremely like, 10: excellent

Table: 8 Sensory Evaluation

4.6. Stability Studies:

|

S.No

|

Time

(Months)

|

Hardness

(kg/cm2)

|

Weight Variation

|

Friability

(%)

|

Drug Content

(%)

|

|

1

|

0

|

10.9

|

2.95

|

0.35

|

99.35

|

|

2

|

1

|

10.8

|

2.90

|

0.35

|

99.08

|

|

3

|

2

|

10.6

|

2.89

|

0.41

|

98.75

|

|

4

|

3

|

9.9

|

2.85

|

0.44

|

98.52

|

Table: 9 Stability Data Of Optimized Formulation F6

4.7. Feed Back Data Analysis:

|

S.NO

|

HEALTHY HUMAN VOLUNTEERS

|

B.PHARM

|

F

|

GENDER

|

COMMENT

|

|

1

|

S.Ranjith Kumar

|

2nd SEM

|

F1

|

M

|

Sweet Taste

|

|

2

|

R.Vitriaiya

|

2nd SEM

|

F1

|

M

|

Sweet With Aromatic

|

|

3

|

A.M.Sajid

|

2nd SEM

|

F1

|

M

|

Sweet Taste

|

|

4

|

M.M.Miqdhadh

|

2nd SEM

|

F1

|

M

|

Aromatic Taste

|

|

5

|

R.Madesh

|

2nd SEM

|

F1

|

M

|

Sweet Taste

|

|

6

|

G.Dhivakar

|

4th SEM

|

F2

|

M

|

Sweet With Aromatic

|

|

7

|

R.Gunasekar

|

4th SEM

|

F2

|

M

|

Sweet Taste

|

|

8

|

A.Kishorth Kumar

|

4th SEM

|

F2

|

M

|

Sweet Taste

|

|

9

|

R.Saravana Vignesh

|

4th SEM

|

F2

|

M

|

Bitter Taste

|

|

10

|

B.Venkatesh

|

4th SEM

|

F2

|

M

|

Sweet Taste

|

|

11

|

M.Gopi

|

6th SEM

|

F3

|

M

|

Aromatic Taste

|

|

12

|

Bharathan

|

6th SEM

|

F3

|

M

|

Sweet Taste

|

|

13

|

K.Gowtham

|

6th SEM

|

F3

|

M

|

Improve Hardness

|

|

14

|

K.Yukash

|

6th SEM

|

F3

|

M

|

Sweet With Aromatic

|

|

15

|

S.Thanigaivelan

|

6th SEM

|

F3

|

M

|

Sweet With Aromatic

|

|

16

|

R.Yogalakshmi

|

2nd SEM

|

F4

|

F

|

Bitter Taste

|

|

17

|

R.Jeevitha

|

2nd SEM

|

F4

|

F

|

Sweet Taste

|

|

18

|

A.Roshini

|

2nd SEM

|

F4

|

F

|

Sweet Taste

|

|

19

|

R.Shalini

|

2nd SEM

|

F4

|

F

|

Sweet Taste

|

|

20

|

Y.Vishnu Priya

|

2nd SEM

|

F4

|

F

|

Sweet Taste

|

|

21

|

M.Ayesha Siddikha

|

4th SEM

|

F5

|

F

|

Sweet With Aromatic

|

|

22

|

R.Gayathri

|

4th SEM

|

F5

|

F

|

Sweet Taste

|

|

23

|

N.Indhu

|

4th SEM

|

F5

|

F

|

Sweet Taste

|

|

24

|

K.Senthamizholy

|

4th SEM

|

F5

|

F

|

Sweet With Aromatic

|

|

25

|

S.Sabitha

|

4th SEM

|

F5

|

F

|

Bitter Taste

|

|

26

|

P.Jothika

|

6th SEM

|

F6

|

F

|

Sweet Taste

|

|

27

|

K.Shakthi

|

6th SEM

|

F6

|

F

|

Sweet With Aromatic

|

|

28

|

S.Yamunadevi

|

6th SEM

|

F6

|

F

|

Sweet Taste

|

|

29

|

S.P.Mahalakshmi

|

6th SEM

|

F6

|

F

|

Sweet Taste

|

|

30

|

P.Priyasree

|

6th SEM

|

F6

|

F

|

Sweet Taste

|

Table: 10 FeedBack Data Analysis

4.8. Label:

Figures: 8 Label

DISCUSSION

The present study was carried out to formulate Herbal Lozenges. The lozenges are using polymers ( Agar , Acacia ) to target the release of pH 7.1. The lozenges are evaluated for Drug content and the lozenges are packed and were subjected to stability studies and The results are presented in appropriate tables and figures.

The Herbal lozenges using heating and congealing technique ( F1 – F6 ). The Herbal lozenges were evaluated such as thickness, hardness, friability, weight variation, drug content, sensory evaluation and stability studies.

F1: The method used in this trial is heating and congealing technique. The base used in glycerin and agar, citric acid, peppermint oil to formulated, Good texture form, good appearances.

F2: The method used in this trial is heating and congealing technique. The base used in glycerin and acacia, citric acid, peppermint oil to formulated, Attraction color, aromatic sweet test.

F3: The method used in this trial is heating and congealing technique. The base used in PEG 1000 and agar, citric acid, peppermint oil to formulated .quick disintegration.

F4: The method used in this trial is heating and congealing technique. The base used in PEG 1000 and acacia, citric acid, peppermint oil to formulated, The hardness of this formulation were better than the above formulation.

F5: The method used in this trial is heating and congealing technique. The base used in PEG 8000 and agar, citric acid, peppermint oil to formulated good hardness with specification limit.

F6: The method used in this trial is heating and congealing technique. The base used in PEG 8000 and acacia, citric acid, peppermint oil to formulated. The lozenges were subjected to Drug content was found to be 99.35 %

SUMMARY AND CONCLUSION

Summary:

The present work involves the formulation of Herbal lozenges by using heating and congealing technique method. Literatures regarding, Herbal lozenges dosage form preparation, excipients selection, manufacturing method, etc., has been collected and reviewed. In this work, selection of excipients was done based on a literature review. Excipients include Agar, Acacia, peppermint oil, citric acid, glycerin, PEG 1000, PEG 8000 Quantities of the excipients.

The prepared lozenges were evaluated for weight variation, hardness, thickness, friability, disintegration time and drug content. All these parameters were found to be within the standard limits. Comparative studies of Herbal lozenges are evaluated for the hardness, thickness, Drug content So the formulation was considered as the confirmatory trial and it was subjected for stability studies.

CONCLUSION

The Herbal lozenges were successfully formulated by heating and congealing technique method using the selected excipient quantities. The formulated lozenges were evaluated parameters as per requirements of standards. The formulated Herbal lozenges with polymer of agar and acacia. From among the entire batches, formulation F6 showed 99.35% drug content. Herbal Lozenges would be a promising formulation to achieve the purpose which treat mouth infection, throat infection, immunity increase, which is useful for patients.

REFERENCES

- Mr.L.Gopi, M.R.Charulatha, “ Development and Characterization of Kalmegh Containing different Types of Lozenges “ – A Research, International Journal of Pharmaceutical Research and Applications, Volume 8, Issue 2 Mar-Apr 2023, pp: 1379-1389

- A Herbert, LL Lieberman, “Medicated Lozenges”, Pharmaceutical dosage forms – tablet series, 2nd Edn ,Marcel Dekker Inc. New York and Basel, 1991, I: 339-467

- Maheshwari R, Jain V, Ansari R, Mahajan SC, Joshi G, A review on lozenges, BBB, 2013, 1-9.

- Shinde SG, Kadam V, Kapse GR, Jadhav SB, Zameeruddin , Bharkad VB, A review on lozenges, IAJPR, 2014, 4, 567-570.

- Pothu R & Yamsani MR, Lozenges formulation and evaluation: A review, IJAPR, 2014, 1, 290-294.

- Esimone CO et al., In vitro Antimicrobial Evaluation of Lozenges Containing Extract of Garlic and Ginger, Int J Health Res. 2010; 3(2): 105-110.

- Deepika modyala, C. Aparna, Prathima Srinivas , Formulation, Evaluation and Characterization of Itraconazole Lozenges, IOSR Journal of Pharmacy and Biological Sciences, 9(3) Ver. I (May -Jun. 2014): 86-94

- Pundir.S, Verma am, Formulation Development and Evaluation of Antiemetic lozenges of Ondansetron hydrochloride, International Journal of Pharmaceutical Research and Bio sciences, 2014; 3(3): 365-372

- Bharkad V B et al., Formulation and evaluation of lozenges tablet of fluconazole Indo American Journal Of Pharm Research 2015 : 5(1): 354-363.

- Monika Bansal et al., Antibacterial, antitussive, antioxidant and toxicological evaluation of Joshanda lozenges, Journal of Applied Pharmaceutical Science Vol. 5 (07): 064-070.

- A. Herbert, Lieberman, Leon Lachman. Pharmaceutical dosage forms – tablet series. “Medicated Lozenges” Marcel Dekker Inc.New York and Basel, 1991; 2nd Edn. I: 339-467

- Dineshmohan S, Vanitha K., Ramesh A, Srikanth G, Akila S. Review on medicated Lozenges. Int J Res Pharm Biomed Sci. 2010; 1(2): 105-108.

- Hemila H, Elizabeth C (2015) The effectiveness of high dose zinc acetate lozenges on various common cold symptoms: A meta-analysis. BMC Fam Pract 16: 1-11.

- George A, Eby III (2010) Zinc lozenges as cure for the common cold: A Review and hypothesis. Med hypotheses 74: 482-492.

- Renuka P., Madhusudan Y., Lozenges Formulation and Evaluation- A Review, International Journal of Advances in Pharmaceutical Research, 2014, 5(5), 290- 298.

- Surbhi C., Review on Lozenges for Oral Bacterial Infection, International Journal of Pharmacy, 2017, 7(1), 16-22.

- Tania S., Tejasavi M., Suxam, Sunil K., Sonia P., Neeraj B., Medicated Lozenges –A Review, World Journal of Pharmacy and Pharmaceutical sciences, 2018, 7(10), 751-756.

- Kirti S., Dr. Sulekha B., Development of Cefixime Lozenges for Treatment of Throat Infection World Journal of Pharmacy and Pharmaceutical Science,2015,4(7), 645-656.

- Shivprasad M., Vaibhav J., Development of Antifungal Lozenges for Treatment of Oropharyngeal Candidiasis, Indo American Journal of Pharmaceutical Research, 2015,5(1), 370-386.

- Laxmi B., Swati G., Sravani P., Indira R., Shailaja P., Formulation and Evaluation of Domperidone Candy Lozenges , World Journal of Pharmacy and Pharmaceutical science, 2017, 6(12), 1167-1175.

V. Anitha*

V. Anitha*

L. Gopi

L. Gopi

10.5281/zenodo.14028700

10.5281/zenodo.14028700