Abstract

Recent advances in nanotechnology demonstrate the increased attention that is now being turned to the supra molecular assembly of simple components for therapeutic and diagnostic purposes. This review contains detail about materials used in synthesis of Nano sponges, different methods of preparation, characterization and applications. Targeted and regulated drug delivery for both topical and oral application is made possible by an inventive and evolving technology known as a Nano sponge. In the pursuit of directing the drug to the required site of action, nanoparticle-based drug delivery systems, such as Nano sponge delivery, are essential. They enhance stability, reduce side effects and modify drug release. Nano sponge formulations involve encapsulation of drugs in a polymeric material and thus provide patient compliance, controlled site-specific drug release, increased formulation efficacy, improved stability and drug dosing. The drugs which have low solubility will be delivered to the site using the Nano sponge formulations with enhanced solubility and increased bioavailability, Nano sponge tablets assist cure conditions like cancer, diabetes mellitus, inflammation, and more.it also contain the new methodology and various formulation that created recently from various category of drug to treat the condition that related to any disease with improving efficacy of that drug.

Keywords

Nanosponges, Generation of Nanoporous, Materials for Biomedical Application.

Introduction

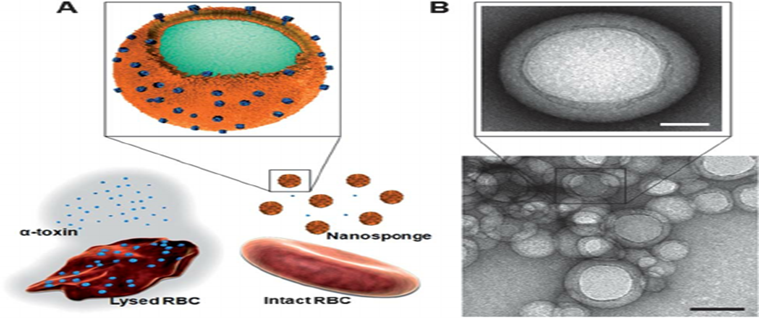

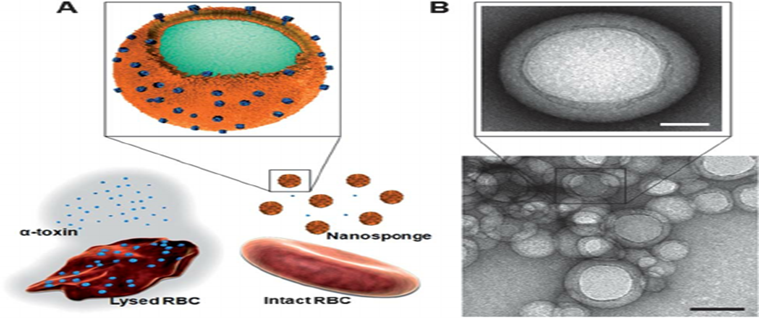

Target-oriented medicine administration, increases in therapeutic efficacy, a decline in side effects, and better dosing regimens are the main trends in the therapeutics sector. Drug delivery systems based on nanoparticles, such as Nano sponge delivery, are crucial in delivering the medication to the intended site of action. Initially, Nano sponge were developed for the topical delivery of drugs with a typical cross-sectional area of less than 1 ?m. These gentle wipes can move throughout the body until they come into contact with the specific target region, adhere briefly, and begin to release the medication in a predictable and controlled manner. A variety of materials can be found within Nano sponges, which are minute structures that resemble meshes (Figure a). Their spherical colloidal nature has been demonstrated, and because of their inclusion and non-inclusion properties, they are believed to have a significant ability to solubilize poorly soluble medications. Nan sponges have been developed and proposed recently for the delivery of pharmaceuticals. In addition to providing longer release and improving the bioavailability of drugs, Nano sponges can solubilize poorly water-soluble pharmaceuticals. The size of Nano sponge ranges from 50 nm to 100 nm, with an average diameter of less than 4 am. This technique is used in prescription drugs, sunscreens, cosmetics, and over-the-counter skin care products. Traditional methods of topical pharmaceutical preparation cause significant accumulation in the dermis and epidermis. Nano sponges eliminate the active not accumulating in the dermis and epidermis. With Nano sponge technology, the irritation caused by the effective medicine is reduced without sacrificing.

Fig. a. (Formulation and development of Nano sponge)

History

|

Year

|

Orignie

|

Scientist

|

Material Nano Sponges

|

ReferEnce

|

|

1960-1980

|

Early Beginnings

|

Solms and

Egli

|

Microencapsulation n

|

5

|

|

1990-2000

|

Nanotechnology

Emergence

|

|

Nano porous materials

|

6

|

|

2000-2010

|

Nano sponges

Concept

|

Min Ma and

De Quan Li

|

- First Nano sponge’s synthesis (2003)

- Biomedical application (2005)

Environmental application (2008)

|

7-8

|

|

2010-2011

|

Recent

Advancement

|

Trotta

|

- Hybrid Nano sponges (2010)

- Stimuli-responsive Nano sponges (2012)

- Biodegradable Nano sponges (2015)

Large scale Nano sponges (2018)

|

9

|

|

2011-2018

|

Notable

Milestones

|

Cavalli

|

- FDA approval (2011)

- Commercialization (2015)

International collaboration (2018)

|

10

|

|

Present

|

Future Direction

|

|

- Personalized medicine

- Advanced biomaterials

- Energy storage and conversion

Space exploration

|

11

|

DISADVANTAGES [15,16]

- Nanosponges have the capacity of encapsulating small molecules, not suitable for larger molecules.

- Dose dumping may occur at times.

- The particulate nature of NSs designed for topical use and the inconvenience associated with their direct application over the skin, are significant limitations.

- The loading ability of NSs rests on degree of crystallization.

Ideal Characterstics [17,20]

Composition Of Nanosponges [21,26]

- Polymers

- Cross linking agents

- Drug molecules

1. Polymers

The kind of polymer has an impact on the production and performance of the Nano sponges. The size of the Nano sponges' cavities determines how much medicine they can hold. The polymer's ability to crosslink is determined by the substitution of functional and active groups. The following list includes some suitable instances of the polymers used in the formulation. Hyper cross-linked polystyrenes, cyclodextrins and their derivatives, including methyl ?-cyclodextrin, alkyloxy-carbonyl cyclodextrins, 2-hydroxy propyl ?-cyclodextrins, copolymers, including poly (Valero lactone–allyl Valero lactone) and poly (Valero lactone oxepanedione), cellulose, and polyvinyl vinyl acetate (PVA) are samples of these materials. The required release and the properties of the drug molecule determine the polymer selection. The polymer must attach to the appropriate ligands for targeted drug release.

2. Cross linker

The type of polymer and the medicinal molecule that has to be formulated determine which crosslinking agents should be used. Carbonyl Di-imidazole, Diphenyl carbonate, Epichloridrine, Glutardehyde, Carboxylic acid di anhydrides, Di-arylcarbonates, Di-Isocyanates, Pyromellitic anhydride, Carbonyl Di-imidazoles, Epichloridrine, Glutraldehyde, Carboxylic acid dianhydrides, 2, 2-bisacrylamides are the crosslinking agents used in the production of nanosponges.

3. Drug molecules

Drug molecules used in the nanosponges should have the following characteristics

- Molecular weight should be in the range of 100-400 Daltons.

- It should consist less than five condensed rings.

- Melting point should below 250 oC.

Solubility in water is less than 10ml.

Types Of Nanosponges [27]

Recent Advancment in Nanosponges

|

Name Of Formulations

|

Name Of Drug

|

Year

|

Reference

|

|

Oral drug formulation

|

- Griseofulvin nanosponges

- Metformin HCl nanosponges

- Ketoconazole nanosponges

- Atorvastatin calcium nanosponges

- Quercetin nanosponges

- Ibuprofen nanosponges

|

2010 - 2018

|

28-33

|

|

Transdermal drug formulation

|

- Nicotine Nano sponge patches

- Fentanyl Nano sponge patches

- Insulin Nano sponge patches

|

2012-2019

|

34

|

|

Ocular drug formulation

|

- Timolol maleate nanosponges

- Moxifloxacin nanosponges

|

2013 - 2016

|

35

|

|

Injectable drug formulation

|

- Paclitaxel Nano sponge suspension

- Doxorubicin Nano sponge liposomes

|

2014 - 2017

|

36

|

|

Other drug formulation

|

- Curcumin nanosponges

- Resveratrol nanosponges

|

2018 - 2019

|

37

|

Recent Work on Nanosponges

|

Sr. No

|

Name of Treatment

|

Category of Drug

|

Name of Drug

|

Action

|

Uses

|

Reference

|

|

1

|

Cancer Treatment

|

Anthracycline antibiotic

Taxane

|

Doxorubicin

Paclitaxel

|

- Targeted delivery to cancer cells

- Enhanced solubility and bioavailability

|

- Breast, lung, and liver cancer treatment

- Ovarian, breast, and lung cancer treatment

|

38-39

|

|

2

|

Antibiotics

|

Fluoroquinolone

|

Ciprofloxacin

|

- Enhanced antibacterial activity

|

- Urinary tract infections

- Respiratory tract infections

|

40

|

|

3

|

Anti-Inflammatory

|

NSAID

|

Ibuprofen

|

- Improved bioavailability and reduced gastrointestinal side effects

|

- Pain relief, fever reduction

|

41

|

|

4

|

Neurological Disorders

|

Acetylcholinesterase inhibitor

|

Rivastigmine

|

- Improved cognitive function in Alzheimer's disease

|

- Alzheimer's disease treatment

|

42

|

|

5

|

Cardiovascular Diseases

|

Statin

|

Atorvastatin

|

- Enhanced bioavailability and reduced side effects

|

- Cholesterol reduction

- cardiovascular disease prevention

|

43

|

|

6

|

Other Applications

|

Peptide hormone

Fat-soluble vitamin

|

Insulin

Vitamin D

|

- Oral delivery and improved bioavailability

- Enhanced bioavailability and improved bone health

|

- Diabetes management

- Bone health, immune system support

|

44 -45

|

Method Of Preparation Of Nanosponges [46-53]

- Melt method

Emulsion Solvent Diffusion Method

Fig No. 2

Ultra sound Assisted Synthesis

Loading of Drug into Nano sponges

Quasi-Emulsion Solvent Diffusion

It is also possible to manufacture the Nano sponges using the quasi-emulsion solvent diffusion process with particular quantities of polymer. Eudragit RS100 was made into the organic phase by dissolving it in the appropriate solvent. The medication is mixed with the solution, and the mixture gets heated to 35°C using ultra sonication. After swirling in water for an hour, the organic phase and the outer phase, or PVA solution, are merged. After that, the Nano sponges are filtered out of the mixture. An air-heated oven set to 40°C is used to dry the Nano sponges for 12 hours.

Fig No. 4

Nano sponges prepared from hyper cross linked cyclodextrin

In this strategy, cyclodextrin reacts with a cross-linker, like carbonyl diimidazoles, diaryl carbonates, or di-isocyanates. When it comes to how successfully the Nano sponges bind to other molecules, their size is determined by their porosity, or surface charge density. It will be determined by the type of cross linker used whether the Nano sponges are acidic or neutral. The ability to encapsulate drugs with various shapes and solubility’s using Nano sponges. In particular, BCS class II pharmaceuticals use them to improve the aqueous solubility of poorly water-soluble medicines.

|

Sr. No

|

Name Of Nano Sponges

|

Chemical Constituents

|

Properties Of Nano Sponges

|

Reference

|

|

1

|

CD-based ether NSs

|

Epichlorohydrin, bisphenol A diglycidyl ether, ethylene glycol diglycidyl ether, 1,4-butanediol diglycidyl ether, E-51 epoxy resin

|

A high level of chemical resistance variable swelling ability

|

23

|

|

2

|

CD-based carbonate NS

|

1,1'- Carbonyl Diimidazole, diphosgene, Dimethyl carbonate, and Diphenyl carbonate

|

Less prone to swelling Stable in mildly alkaline and acidic liquids Small surface area

|

23

|

|

3

|

CD-based ester NSs

|

dianhydrides, Epiclon-B-4400; citric acid, and 2,6-naphthalene dicarboxylic acid (NDCA

|

Easily hydrolyzed in aqueous media

|

24

|

|

4

|

CD-based urethane/ carbamate NSs

|

Di isocyanates like, methylene diphenyl diisocyanate

|

A rigid structure,

Resistant to chemical deteriorationNegligible swelling

|

25

|

New Methodology for The Preparation of NanospongeS [54,55]

Nano Sponge Formulation Advantages

Nano Sponge Formulation Disadvantages

Nanosponge Limitations

|

Physical Limitations

|

- Aggregation and settling

- Instability in aqueous environments

- Limited shelf-life due to moisture sensitivity

- Potential for oxidation or photo degradation

- Difficulty in achieving consistent particle size and distribution

|

|

Chemical Limitations

|

-

- Limited chemical stability

- Potential for degradation or hydrolysis

- Incompatibility with certain drugs or excipients

- Limited solubility in certain solvents

- Potential for chemical interactions with biological molecules

|

|

Biological Limitations

|

- Potential for cytotoxicity or genotoxicity

- Inflammation or immune response

- Biodegradation products may be toxic

- Uncertainty surrounding long-term biocompatibility

- Potential for accumulation in organs or tissues

|

|

Pharmacological Limitations

|

- Unpredictable pharmacokinetics

- Potential for altered bio distribution

- Limited understanding of pharmacodynamics

- Difficulty in optimizing dosing regimens

- Potential for drug-drug interactions

|

|

Toxicological Limitations

|

- Potential for toxicity due to nanoscale size

- Uncertainty surrounding chronic toxicity

- Limited understanding of environmental impact

- Potential for bioaccumulation

- Challenges in ensuring safe handling and disposal

|

|

Regulatory Limitations

|

-

- Limited guidance on Nano sponge regulations

- Uncertainty surrounding regulatory classification

- High costs associated with regulatory compliance

- Potential for lengthy approval processes

- Limited standardization in Nano sponge characterization

|

|

Scalability Limitations

|

- Difficulty in scaling up production

- High manufacturing costs

- Limited availability of cGMP facilities

- Potential for contamination or batch failures

- Challenges in ensuring reproducibility

|

|

Economic Limitations

|

-

- High development costs

- Limited market demand or competition

- Potential for patent disputes

- Challenges in securing funding or investment

- Uncertainty surrounding reimbursement policies

|

|

Environmental Limitations

|

- Potential for environmental contamination

- Uncertainty surrounding Nano sponge degradation

- Limited understanding of ecological impact

- Potential for bioaccumulation

- Challenges in ensuring sustainable production

|

Nanosponge Marketed Formulation

|

Type Of Formulation

|

Name Of Formulation

|

Uses

|

|

Pharmaceuticals

|

- Abraham

- Doxia

- Amboise

- Paclitaxel

|

- Breast cancer treatment

- Cancer treatment

- Fungal infection treatment

- Breast cancer treatment

|

|

Cosmetics and Skincare

|

- Neutrogena's Hydro Boost Water Gel

- L’Oréal’s Revivalist

- Nivea's Q10 Plus

- La Roche

|

- Moisturizing cream

- Anti-aging cream

- Anti-aging cream

- Posey’s Tolerance Ultra Fluid

|

|

Medical Devices

|

- 3M's Tegaderm Nano sponge Dressing

- Johnson & Johnson's Bio absorbable Nano sponge Scaffold

- Medtronic's Nano sponge-based Wound Dressing

|

- Wound care

- Tissue engineering

- Wound care

|

|

Food and Nutrition

|

- Nestlé’s Nano sponge-based Food Packaging

- Danone's Nano sponge-based Probiotic Delivery

|

- Food preservation

- Probiotic supplements

|

|

Other Marketed Products

|

- BASF's Nano sponge-based Water Purification System

- 3M's Nano sponge-based Air Purification System

|

- Water treatment

- Air filtration

|

|

US Patents

|

International Patents

|

Patent Assignees

|

Patent Categories

|

Recent Patent Filings

|

|

1. US 9,011,881 (2015): "Nano sponge" - A New Class of Organic-Inorganic Hybrid Materials

2. US 10,456,91(2019): "Mesoporous Silica Nano sponge-Based Drug Delivery Systems"

3. US 9,435,949 (2016): "Titanium Dioxide Nano sponges for Biomedical Applications"

4. US 10,131,94(2018): "Silicon-Based Nano sponge Scaffolds for Tissue Engineering"

5. US 9,949,072 "Nano sponge-Based Wound Dressing for Enhanced Wound Healing" (2018

|

1. WO 2018/075,331 (2018): "Nano sponge-Based System for Delivery of Therapeutic Agents"

2. EP 3,443,191 (2019): "Mesoporous Silica Nano sponges for Biomedical Applications"

3. CN 109,531,442 (2019): "Titanium Dioxide Nano sponge-Based Biomedical Materials"

|

1.University of California, Los Angeles (UCLA)

2. Massachusetts Institute of Technology (MIT)

3. Harvard University

4. 3M

5. Johnson & Johnson

6. Merck

7. Pfizer

8. Sanofi

9. GlaxoSmithKline

10. Celgene

|

1.Biomedical applications (drug delivery, tissue engineering, wound healing)

2.Materials science (Nano sponge synthesis, characterization)

3. Pharmaceutical formulations (Nano sponge-based drug delivery systems)

4. Medical devices (wound dressings, implants)

5. Energy storage and conversion (Nano sponge-based electrodes)

|

1.US2022/023,133 (2022): "Nano sponge-Based System for Delivery of RNA Therapeutics"

2.WO2022/075,211 (2022): "Silicon-Based Nano sponge Scaffolds for 3D Cell Culture"

|

Factor Affecting Nanosponges [56,61]

1.Depending on property of crosslinked and polymer used

In order to create a three-dimensional structure, NSs need cross linkers. The form of a cross-link used helps determine the extent of drug immobilization and shapes organ targeting. It is determined by the type the crosslinked that is used whether the NS dissolves in water or another solvent. The objective is to crosslink with epichlorohydrin to produce hydrophilic NSs. The advantages of using hydrophobic NSs to deliver medications include better drug absorption via biological membranes and useful transport for medications in formulations meant for instant release. Water-hating NSs are made using crossovers that involve isocyanates, carbonyl imidazole’s, pyromellitic anhydride (PVA), and DPC. Hydrophobic NSs are a continuous release medication delivery system for patients who prefer water.

2. Medium used to show interaction and the property of drug

A chemical must fulfil certain criteria in order to be approved for encapsulation and selected for integration into neural scaffolds (NSs). The pharmaceutical molecule's molecular mass should be within hundred and four hundred Da and less than five compacted rings. It is advised to keep the solubility below 10 mg/ml within water and the melting point below 250 °C. Following capturing in NSs, compounds with melting points that are elevated demonstrate a lower stabilization constant value, which leads to the discovery of uneven complex within the drug and NSs. Additionally, drugs with high points of melting may not be as trapped, which will affect how much they can load. One important element influencing the pace of drug loading is the drug loading medium. Of medication release, since it helps the targeted chemical engage with the holes in the NSs. In a water-based medium, the organic substance molecule accumulates in the hydrophilic cavities of NSs; in a chemical solvent medium, the molecules of organic compounds are released from the NSs. Among both the host and the guest molecules, the magnitude of the attraction is determined by both physical and chemical forces.

3. The substitution degree for crosslinking

The number of substituents and the degree of polymerization are strongly related; more replacements might lead to a larger degree of cross linkage, which creates extremely porous NSs with internal mesh networking. Because the functional group occupies distinct places on the parent molecule, an adjustment in the production method could lead to a material with varied physicochemical properties. The final NSs value, whose value depends on the manner of manufacture and material purity of the product, establishes the degree of polymer's importance.

4. Complexation nature

An increased degree of crosslinking caused by a greater amount of replacements can result in highly porous NSs with internal mesh networking. There is a substantial correlation between the amounts of substituents with the level of binding. Because each of the functional groups are positioned differently on the parent molecule, variations in the production process can result in a material with differing physicochemical properties. The final value of the NSs, which hinges on the product's processing and material purity, illustrates exactly how significant an amount of polymer substitution is.

Evaluation Parameters For Determination Of Nano Sponges Particle Size [62, 69]

During the polymerization process, the size of the particles can be controlled to produce free-flowing powders with exceptional aesthetic qualities. Using a Malvern Zeta sizer or laser light diffractometric, the particle sizes of loaded and unloaded Nano sponges will be investigated. Larger particles exceeding 30 m may give the application a gritty appearance, therefore particles between 10 and 25 m are most suited for usage in the finished topical formulation.

1. FTIR (Fourier transform infrared) analysis

In order to confirm whether a chemical bond connection between the medication and the polymer was possible, an infrared spectroscopy technique called Fourier transform was employed. By applying charcoal black as the reference, the materials were scanned in the 400–4000 cm-1 range. The signal and moisture content were both decreased.

2. Thin-Layer Chromatography

A drug molecule's Fry value significantly decreases in thin-layer chromatography, which aids in determining whether a complex involving the drug with Nano sponges has formed. There is a reversible inclusion complexation between the living thing and visiting molecules. During the chromatographic process, the complex may thus fully split into the guest molecule and host molecules, leaving only their individual spots on the TLC plate.

3. Solubility studies

Among the methods used to assess a medication's solubility and bioavailability are inclusion complexes. The inclusion aggregates of Nano sponges are most frequently examined using this method. One can use the phase solubility plot to determine the degree of completion. Drugs' solubility is investigated through solubility experiments to determine their pH level, the dissolution profile, and contributory factor.

4. Determination of loading efficiency and production yield

The amount of drug not entrapped is subtracted from the total amount of drug to calculate the prepared Nano sponge loading efficiency. The effectiveness of drug entrapment will be evaluated by separating the unentrapped substance using any appropriate analytical technique. the procedure that uses dialysis, gel filtration, and ultra-centrifugation to separate unentrapped medicines. Effective amounts of drugs in Nano sponge is equal to loading efficiency.

5. Microscopic study

Under a microscope, medicines and Nano sponges can be examined using electron transmission microscopes and scanning electron microscopes. The production of inclusion complexes is demonstrated by the difference between the product seen under the microscope's light and the crystallization state.

6. Zeta potential determination

When two fluid layers are connected by dispersed particles, the immobile layer and the dispersion medium have different potentials, which is known as the zeta potential. The potential for zeta is the most important and fundamental measure of the consistency of the colloidal dispersion. By putting an extra electrode or zeta separator in a particle size device, the potential of zeta can be found. Whenever this zeta potential value rises, the colloidal dispersion becomes more stable. Hydrogen bonding is done by the absorption bands, which often grow, shift to a lower frequency, and become stronger. The stretching vibration band moves most closely to the hydrogen bond of the hydroxyl group.

7. Infra-Red spectroscopy

The solid-state drug molecules' interaction with the Nano sponge is evaluated using infrared spectroscopy. Following the formation of a complex, Nano sponge band alterations are frequently quite minor. If the guest molecules make up less than 25% of the entire complex, the wavelengths of the Nano sponge spectrum readily cover any bands that would represent the guest molecules. Compared to alternative methods, the approach used is less revealing and frequently insufficient to identify the inclusion complexes. Drugs with specific bands, like sulfonyl or carbonyl groups, can only be evaluated via infrared spectroscopy. Using the infrared spectrum, one can examine how hydrogen behaves in different functional groups.

8. Thermo-analytical methods

To determine if the pharmaceutical substance changes in any manner before the Nano sponge heats up, thermoanalytic techniques are employed. The drug material could oxidize, melt, evaporate, dissolve, or go through a polymorphic transition. The drug's evolving composition indicates the growth of the complex. Thermograms generated by The DTA and DSC can be examined for changes, such as peaks growing, shifting, or disappearing completely. Weight loss changes could indicate inclusion complexes.

9. Permeation studies

For the diffusion studies, which were carried out at 37±1°C with 250 ml of phosphate buffer (pH 7.4) as the dissolving media, a produced Nano sponge sample (0.5 g) can be put on a cellophane membrane. At 1, 2, 3, 4, 5, 6 7 and 8 hours, five milliliters of each sample can be taken out and replaced with an equivalent amount of brand-new dissolving media.

10. Drug release kinetics

In order to explore the mechanism of releasing medications from the Nano sponge, the release data was evaluated using the simplest order, initial order, Higuchi, Korsemeyer-Peppas, Hixon Crowell, Koch, and Makoid-Banakar models. The data can be analysed with Graph Pad Prism program. The program determines which of several non-linear function parameters best fits the experimental data.

Application [65,70]

Silent Features

By varying the ratios of polymers to crosslinking agents, Nano sponges—which are composed of up of particles of a specific size—can be rendered polar or non-polar. Nano sponges range in void polarity and are less than 1 am. There can be crystalline or para-crystalline forms. The crystallized form of Nano sponges plays a role for drug interaction because the degree of crystallization greatly affects how efficient it is of stackable Nano sponges. According to previous literature, Nano sponges or Para crystalline have been shown to have various kinds of drug-loading capabilities. They have been discovered to be stable between 1-11 °P and 130 °C. Nanoparticles have been discovered to be permeable, biodegradable, and non-toxic. Their three-dimensional structure allows them to transport, encapsulate, and release medications and other substances in an observable way. When water is added to Nano sponges, a clear to opalescent colloidal solution is created. This solution can be recovered by solvent distillation or through desorption with microwave and ultrasonic waves. Due to their ability to interact with several functional groups—which can be increased by employing synthetic linkers that specifically target specific sites—they indicate targeted release of numerous compounds. Magnetic fields from the outside can be used to target expelled by adding magnetic abilities to a Nano sponge configuration through the extension of ferromagnetic and other magnetic materials over the production process. The material preferred by consumers is nan sponges due to their many benefits, including as the capacity to deliver a substance's sustained release for as long as twenty-four hours. To encapsulate liquids that aren't soluble, providing increased flexibility, stability, and reduced excitability. Nan sponges supply a number of advantages but they also have some drawbacks. Although their bodies are suited to incorporating macromolecules and oligonucleotides, the Nan sponges mostly incorporate small medicinal compounds. The quantity of crosslinking has a consequence on the ability to load drugs because it controls the amount of unoccupied space in the Nano sponge that is readily accessible for loading.

CONCLUSION

According to the previous study, Nano sponges, a novel type of drug delivery vehicles, offer controlled drug administration for topical application. These microscopic particles can carry polar and slimy substances, and they can also increase the dispersion of poorly soluble molecules. Their small particle size and spherical shape allow them to be produced in an assortment of delivery modes, including topical and oral parenteral dosage forms. In a controlled and predictable manner, the medication will emerge from Nano sponges. The Nano sponges provide site-specific drug delivery and longer dosage intervals. They work in many different industries, such as oil clean up, floriculture, and the food industry. They are shown to have a powerful ability to protect important biomarkers in a number of diseases, including as biocatalysts from cancer and physiochemical breakdown. Future developments in drug delivery methods will be greatly aided by Nano sponges.

REFERENCES

- Zain Uddin R, Zahner Z, Sangshetti JN, Momin M. Enhancement of oral bioavailability of anti-HIV drug rilpivirine HCl through nanosponge formulation. Drug development and industrial pharmacy. 2017 Dec 2; 43(12):2076-84

- Jain PD, Girase ML, Borse KB, Karandikar YK, Chintavar S, Kharche AS, Gupta AM. “NANOSPONGE: A VERSATILE DRUG DELIVERY SYSTEM”-REVIEW. International Journal of All Research Writings. 2019 May 2; 1(11):110-5

- Shringirishi M, Prajapati SK, Mahor A, Alok S, Yadav P, Verma A. Nanosponges: a potential nanocarrier for novel drug delivery-a review. Asian pacific journal of tropical disease. 2014 Sep 1;4: S519-26.

- Pandey PJ. Multifunctional nanosponges for the treatment of various diseases: A review. Asian J. Pharm Pharmacol. 2019;5 (2):235-48

- Trotta F, Cavalli R. Characterization and application of new hyper cross-linked cyclodextrins Compos Interfaces 2009; 16:39-48.

- Ansari KA, Vavia PR, and Trotta F, Cavalli R. Cyclodextrin-based nanosponges for delivery of resveratrol: in vitro characterisation, stability, cytotoxicity and permeation study. Aaps Pharmscitech. 2011 Mar; 12:279-86.

- Swaminathan S, Pastero L, Serpe L, Trotta F, Vavia P, Aquilano D, Trotta M, Zara G, Cavalli R. Cyclodextrin-based nanosponges encapsulating camptothecin: Physicochemical characterization, stability and cytotoxicity. European journal of pharmaceutics and biopharmaceutics. 2010 Feb 1;74(2):193-201.

- Ealia SA, Saravanakumar MP. A review on the classification, characterisation, synthesis of nanoparticles and their application. InIOP conference series: materials science and engineering 2017 Nov 1 (Vol. 263, No. 3, p. 032019). IOP Publishing.

- Opeyemi OT, opeyemi Adegbenro O. Development and characterization of direct compressed matrix mini tablets of naproxen sodium. Universal Journal of Pharmaceutical Research. 2018 Nov 15.

- Richhariya N, Prajapati SK, Sharma UK. Nanosponges: an innovative drug delivery system. World J Pharm Res. 2015 May 5;4(7):1751-3.

- Biswas GR, Majee SB, Roy A. Combination of synthetic and natural polymers in hydrogel: An impact on drug permeation. Journal of Applied Pharmaceutical Science. 2016 Nov 29;6(11):158-64.

- Tiwari K, Bhattacharya S. The ascension of nanosponges as a drug delivery carrier: preparation, characterization, and applications. Journal of Materials Science: Materials in Medicine. 2022 Mar;33(3):28

- Dhumal GJ, Kulkarni AS, Bandal KK, Dambe RH, Thorat VR, Patil TT, Dhayagonde KK. NANOSPONGES: A New Approach for Drug Delivery System.

- Tamkhane V, Sharma PH. Nanosponge-a novel drug delivery system. Journal of Current Pharma Research. 2014 Apr 1;4(3):1186

- Nagaraja k, sukeerthi b, arunjyothi b, sravani c, tuljarani d. A review of the methods involved in the preparation of nanosponges.

- Patil PP, Aher SJ, Raut ID, Bandgar S, Ghule PS. The new insight of nanosponges in topical drug delivery.

- Swaminathan, S., Cavalli, R., Trotta, F., Ferruti, P., Ranucci, E., Gerges, I., Manfredi, A., Marinotto, D. and Vavia, P.R., 2010. In- vitro release modulation and conformational stabilization of a model protein using swellable polyamidoamine nanosponges of ?-cyclodextrin. Journal of inclusion phenomena and macrocyclic chemistry, 68, pp.183-191.

- Setijadi E, Tao L, Liu J, Jia Z, Boyer C, Davis TP. Biodegradable star polymers functionalized with ?-cyclodextrin inclusion complexes. Biomacromolecules. 2009 Sep 14;10(9):2699-707.

- Swaminathan S, Pastero L, Serpe L, Trotta F, Vavia P, Aquilano D, Trotta M, Zara G, Cavalli R. Cyclodextrin-based nanosponges encapsulating camptothecin: Physicochemical characterization, stability and cytotoxicity. European journal of pharmaceutics and biopharmaceutics. 2010 Feb 1;74(2):193-201.

- Selvamuthukumar S, Anandam S, Krishnamoorthy K, Rajappan M. Nanosponges: A novel class of drug delivery system-review. Journal of Pharmacy & Pharmaceutical Sciences. 2012 Jan 17;15(1):103-11.

- Challa R, Ahuja A, Ali J, Khar R. Cyclodextrins in drug delivery: an updated review. Aaps Pharmscitech. 2005 Jun;6: E329-57.

- Ansari KA, Vavia PR, Trotta F, Cavalli R. Cyclodextrin-based nanosponges for delivery of resveratrol: in vitro characterisation, stability, cytotoxicity and permeation study. Aaps Pharmscitech. 2011 Mar; 12:279-86.

- Guo L, Gao G, Liu X, Liu F. Preparation and characterization of TiO2 nanosponge. Materials Chemistry and Physics. 2008 Oct 15;111(2-3):322-5.

- Lai X, Zeng X, Li H, Yin C, Zhang H, Liao F. Synergistic effect of phosphorus?containing nanosponges on intumescent flame?retardant polypropylene. Journal of applied polymer \science. 2012 Aug 5;125(3):1758-65.

- Utzeri G, Matias PM, Murtinho D, Valente AJ. Cyclodextrin-based nanosponges: Overview and opportunities. Frontiers in chemistry. 2022 Mar 24; 10:859406.

- Pedrazzo AR, Caldera F, Zanetti M, Appleton SL, Dhakar NK, Trotta F. Mechanochemical green synthesis of hyper-crosslinked cyclodextrin polymers. Beilstein journal of organic chemistry. 2020 Jun 29;16(1):1554-63.

- Gholibegloo E, Mortezazadeh T, Salehian F, Forootanfar H, Firoozpour L, Foroumadi A, Ramazani A, Khoobi M. Folic acid decorated magnetic nanosponge: An efficient nanosystem for targeted curcumin delivery and magnetic resonance imaging. Journal of colloid and interface science. 2019 Nov 15; 556:128-39.

- Sengupta P, Das A, Khanam J, Biswas A, Mathew J, Mondal PK, Romero EL, Thomas S, Trotta F, Ghosal K. Evaluating the potential of ethyl cellulose/eudragit-based griseofulvin loaded nanosponge matrix for topical antifungal drug delivery in a sustained release pattern. International Journal of Biological Macromolecules. 2024 Sep 1; 276:133953.

- Pawar AY, Jadhav KR, Rathod SP, Sanap AS, Umekar MJ. Formulation and Evaluation of Nanosponges Loaded Hydrogel of Metformin Hydrochloride. Indian Journal of Pharmaceutical Education & Research. 2023 Jan 1;57(1).

- Jadhao UT, Sayali RP, Gunesh DN, Shital SD, Sneha LS. Formulation and evaluation of nanosponge gel containing ketoconazole. Innovations in Pharmaceuticals and Pharmacotherapy. 2021;9(1):15-24.

- Zidan MF, Ibrahim HM, Afouna MI, Ibrahim EA. In vitro and in vivo evaluation of cyclodextrin-based nanosponges for enhancing oral bioavailability of atorvastatin calcium. Drug development and industrial pharmacy. 2018 Aug 3;44(8):1243-53.

- Zhang W, Gai H, Zhang Q, Zhang D, Zheng S, Zhu G. Preparation, characterization and properties of quercetin cyclodextrin nanosponges. Journal of Inclusion Phenomena and Macrocyclic Chemistry. 2024 Oct 22:1-2.

- Abbas N, Irfan M, Hussain A, Arshad MS, Hussain SZ, Latif S, Bukhari NI. Development and evaluation of scaffold-based nanosponge formulation for controlled drug delivery of naproxen and ibuprofen. Tropical Journal of Pharmaceutical Research. 2018 Oct 5;17(8):1465-74.

- Makwana R, Patel T. Formulation and optimization of ornidazole loaded microsponge for vaginal drug delivery. Journal of Survey in Fisheries Sciences. 2023 Dec 16;10(3):724-34.

- Zhao R, Li J, Wang J, Yin Z, Zhu Y, Liu W. Development of timolol-loaded galactosylated chitosan nanoparticles and evaluation of their potential for ocular drug delivery. AAPS PharmSciTech. 2017 May; 18:997-1008.

- Torne SJ, Ansari KA, Vavia PR, Trotta F, Cavalli R. Enhanced oral paclitaxel bioavailability after administration of paclitaxel-loaded nanosponges. Drug delivery. 2010 Aug 1;17(6):419-25.

- Mashaqbeh H, Obaidat R, Al-Shar’i N. Evaluation and characterization of curcumin-?-cyclodextrin and cyclodextrin-based nanosponge inclusion complexation. Polymers. 2021 Nov 24;13(23):4073.

- Narender BR, Rao PR. Formulation and evaluation of anticancer drug (doxorubicin) loaded nanosponges. Indo American journal ofPharmaceutical Research. 2019;9(12):572-83.

- Clemente N, Argenziano M, Gigliotti CL, Ferrara B, Boggio E, Chiocchetti A, Caldera F, Trotta F, Benetti E, Annaratone L, Ribero S. Paclitaxel-loaded nanosponges inhibit growth and angiogenesis in melanoma cell models. Frontiers in pharmacology. 2019 Jul 12; 10:776.

- Pyrak B, Rogacka-Pyrak K, Gubica T, Szeleszczuk ?. Exploring cyclodextrin-based nanosponges as drug delivery systems: Understanding the physicochemical factors influencing drug loading and release kinetics. International Journal of Molecular Sciences. 2024 Mar 20;25(6):3527.

- Latif S, Ijaz QA, Afzal H, Siddique MI, Hussain A, Arshad MS, Bukhari NI, Abbas N. Solubility and dissolution rate enhancement of ibuprofen by cyclodextrin based carbonate nanosponges. Pakistan Journal of Pharmaceutical Sciences. 2021 May 2;34.

- Dighe S, Jog S, Momin M, Sawarkar S, Omri A. Intranasal Drug Delivery by Nanotechnology: Advances in and Challenges for Alzheimer’s Disease Management. Pharmaceutics. 2023 Dec 29;16(1):58.

- Khafagy ES, Motawee AO, Ghorab MM, Gardouh AR. Atorvastatin-loaded pro-nanolipospheres with ameliorated oral bioavailability and antidyslipidemic activity. Colloids and Surfaces B: Biointerfaces. 2023 Jul 1; 227:113361

- Appleton SL, Tannous M, Argenziano M, Muntoni E, Rosa AC, Rossi D, Caldera F, Scomparin A, Trotta F, Cavalli R. Nanosponges as protein delivery systems: Insulin, a case study. International Journal of Pharmaceutics. 2020 Nov 30; 590:119888.

- Jampilek J, Kos J, Kralova K. Potential of nanomaterial applications in dietary supplements and foods for special medical purposes. Nanomaterials. 2019 Feb 19;9(2):296.

- Tejashri G, Amrita B, Darshana J. Cyclodextrin based nanosponges for pharmaceutical use: A review. Acta pharmaceutica. 2013 Sep 30;63(3):335-58

- Lala R, Thorat A, Gargote C. Current trends in ?-cyclodextrin based drug delivery systems. Int J Res Ayur Pharm. 2011 Sep 1;2(5):1520-6.

- Moya-Ortega MD, Alvarez-Lorenzo C, Concheiro A, Loftsson T. Cyclodextrin-based nanogels for pharmaceutical and biomedical applications. International journal of pharmaceutics. 2012 May 30;428(1-2):152-63.

- Trotta F, Cavalli R, Tumiatti V, Roggero C, Vallero R. Ultrasound-assisted synthesis of cyclodextrin-based nanosponges.

- Swaminathan S, Pastero L, Serpe L, Trotta F, Vavia P, Aquilano D, Trotta M, Zara G, Cavalli R. Cyclodextrin-based nanosponges encapsulating camptothecin: Physicochemical characterization, stability and cytotoxicity. European journal of pharmaceutics and biopharmaceutics. 2010 Feb 1;74(2):193-201.

- Indira B, Bolisetti SS, Samrat C, Reddy SM, Reddy NS. Nanosponges: a new era in drug delivery. Journal of pharmacy research. 2012;5(12):5293-6.

- Das D, Afnan T, Chhetri P, Dutta Chakraborty D, Chakraborty P. An outlook towards nano-sponges: a unique drug delivery system and its application in drug delivery. Current Drug Delivery. 2023 Aug 1;20(7):884-903.

- Simranjot K, Sandeep K. Nanosponges: Present aspects and future challenges. Indo American Journal of Pharmaceutical Sciences. 2018 Sep 1;5(9):9390-8.

- Mane PT, Wakure BS, Wakte PS. Cyclodextrin based nanosponges: a multidimensional drug delivery system and its biomedical applications. Current Drug Delivery. 2021 Dec 1;18(10):1467-93.

- Iravani S, Varma RS. Nanosponges for drug delivery and cancer therapy: Recent advances. Nanomaterials. 2022 Jul 16;12(14):2440.

- Gidwani B, Vyas A. A comprehensive review on cyclodextrin?based carriers for delivery of chemotherapeutic cytotoxic anticancer drugs. BioMed research international. 2015;2015(1):198268.

- Dubey P, Sharma HK, Shah S, Tyagi CK, Chandekar AR, Jadon RS. Formulations and evaluation of Cyclodextrin complexed Ceadroxil loaded nanosponges. Int J Drug Deliv. 2017 Oct 31;9(3):84.

- Kamble M, Zahner Z, Mokale S, Zain Uddin R. Formulation optimization and biopharmaceutical evaluation of imatinib mesylate loaded ?-cyclodextrin nanosponges. Pharmaceutical Nanotechnology. 2019 Dec 1;7(5):343-61.

- Ravi SC, Krishnakumar K, Nair SK. Nano sponges: A targeted drug delivery system and its applications. GSC Biological and Pharmaceutical Sciences. 2019 Jun 30;7(3):040-7.

- Moya-Ortega MD, Alvarez-Lorenzo C, Concheiro A, Loftsson T. Cyclodextrin-based nanogels for pharmaceutical and biomedical applications. International journal of pharmaceutics. 2012 May 30;428(1-2):152-63.

- Swaminathan S, Vavia PR, Trotta F, Torne S. Formulation of betacyclodextrin based nanosponges of itraconazole. Journal of inclusion phenomena and macrocyclic chemistry. 2007 Apr; 57:89-94.

- Shivani S, Poladi KK. Nanosponges-novel emerging drug delivery system: A review. International journal of pharmaceutical sciences and research. 2015 Feb 1;6(2):529.

- Trotta F, Zanetti M, Cavalli R. Cyclodextrin-based nanosponges as drug carriers. Beilstein journal of organic chemistry. 2012 Nov 29;8(1):2091-9.

- Cavalli R, Akhter AK, Bisazza A, Giustetto P, Trotta F, Vavia P. Nanosponge formulations as oxygen delivery systems. International journal of pharmaceutics. 2010 Dec 15;402(1-2):254-7.

- Sharma R, Walker RB, Pathak K. Evaluation of the kinetics and mechanism of drug release from econazole nitrate nanosponge loaded carbapol hydrogel.

- Farooq SA, Saini VI, Singh RA, Kaur KA. Application of novel drug delivery system in the pharmacotherapy of hyperlipidemia. J Chem Pharm Sci. 2013; 6:138-46.

- Joshi dc. Nano sponges: a novel approach for targeted drug delivery systems.

- Vyas A, Saraf S, Saraf S. Cyclodextrin based novel drug delivery systems. Journal of inclusion phenomena and macrocyclic chemistry. 2008 Oct; 62:23-42.

- Sherje AP, Dravyakar BR, Kadam D, Jadhav M. Cyclodextrin-based nanosponges: A critical review. Carbohydrate polymers. 2017 Oct 1; 173:37-49.

- Trotta F, Dianzani C, Caldera F, Mognetti B, Cavalli R. The application of nanosponges to cancer drug delivery. Expert opinion on drug delivery. 2014 Jun 1;11(6):931-41.

- Zuberi SA, Sheraz MA, Ali SA, Shah MR, Mujahid S, Ahmed S, Anwar Z. Nanosponges-based drug delivery system for the cosmeceutical applications of stabilized ascorbic acid. Current Drug Delivery. 2023 Dec 1;20(10):1504-24.

- Nigam A, Kumar S. Nanosponges for Environmental Remediation. Gulati S, editor. Springer; 2023 Oct 11

Jayashri Dandale*

Jayashri Dandale*

Sadhana Shahi

Sadhana Shahi

10.5281/zenodo.14565645

10.5281/zenodo.14565645