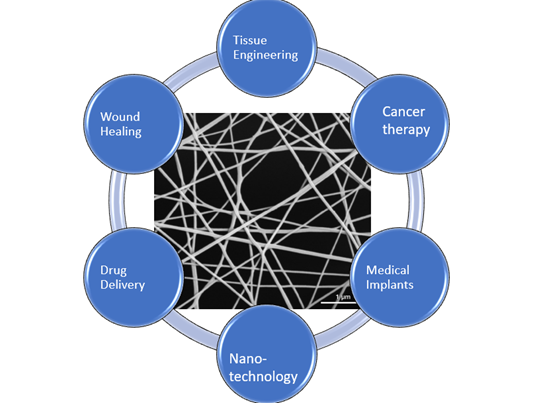

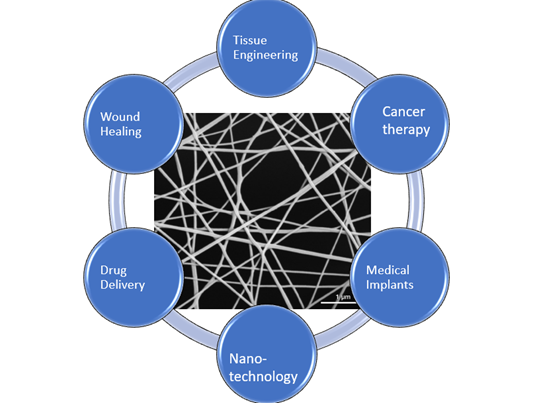

Electrospinning has emerged as a versatile and efficient technique for fabricating nanofibers with diverse applications across multiple fields. This review article explores the fundamental principles, recent advancements, and prospects of electrospinning technology. The process involves the application of an electric field to draw charged polymer solutions or melts into ultrafine fibers, resulting in materials with high surface area-to-volume ratios and unique properties. We discuss the key parameters influencing fibre formation, including solution properties, processing conditions, and environmental factors. Recent innovations in electrospinning setups, such as coaxial, multi-jet, and needleless configurations, are examined, highlighting their potential to enhance fibre production and expand the range of achievable structures. The article also delves into the various materials employed in electrospinning, from synthetic polymers to natural biopolymers and composite systems. We review the wide-ranging applications of electrospun nanofibers in fields such as tissue engineering, drug delivery, filtration, energy storage, and sensors. Furthermore, we explore the integration of electrospinning with other fabrication techniques and its role in developing smart and multifunctional materials. Looking ahead, we identify emerging trends and challenges in electrospinning research, including scalability, sustainability, and the incorporation of stimuli-responsive components. This comprehensive review aims to provide researchers and industry professionals with insights into the current state of electrospinning technology and its potential to address future societal and technological needs.

Tissue engineering, Multijet electrospinning, Electrospinning, Multi-layered electrospinning, electrospun fibers

The ability to create nanofibers with remarkable qualities and versatility through a straightforward yet effective process has allowed electrospinning to transform the fields of materials science and engineering completely. Over the past few decades, this technology has garnered substantial attention in both academia and industry. It uses the power of electrostatic forces to generate fibers with widths ranging from a few nanometers to several micrometers1. The aforementioned attributes of electrospun nanofibers, namely their high surface area-to-volume ratio, tunable porosity, and capacity to integrate diverse functional materials, have facilitated their extensive utilization in a multitude of fields, such as tissue engineering, drug delivery, filtration, energy storage, and sensors2. The earliest known instances of the electrospinning concept are from the early 1900s, when Cooley and Morton submitted patents in 1902 and 1903, in that order. Reneker and colleagues' work, which showed how the process could be used to create nanofibers from different polymer solutions, was the main reason for the technique's resurgence in the 1990s. Since then, electrospinning has advanced quickly, with ongoing advancements in the sophistication of the fabrication methods as well as our grasp of the fundamental principles. Fundamentally, electrospinning works by applying a high voltage to a melt or polymer solution, which causes an electrically charged jet to be pulled in the direction of a grounded collector. Solid nanofibers are created as the jet moves through the air because the solvent evaporates or the melt solidifies3. A complicated interaction of forces, including surface tension, viscoelastic forces, and electrostatic repulsion, controls this process, which appears to be straightforward. Comprehending and managing these forces is crucial to customize the characteristics of the resultant nanofibers and broaden the spectrum of materials amenable to electrospun success3. The adaptability of electrospinning in terms of material selection is one of its main advantages. With this method, a large variety of polymers—both synthetic and natural—can be converted into nanofibers1. Because of their adaptable qualities and ease of processing, synthetic polymers including polyethylene oxide PEO, polycaprolactone PCL, and poly lactic-co-glycolic acid PLGA have been the subject of much research4. Because they are biocompatible and biodegradable, natural polymers like cellulose derivatives, chitosan, and collagen have also attracted interest, especially in biomedical applications5. Furthermore, new opportunities for the development of multifunctional materials with improved qualities have been made possible by the ability to insert functional components into the fibers during the electrospinning process, such as medicines, proteins, and nanoparticles. Significant progress has been made in electrospinning technology in recent years to overcome the hindrance of skill development6. Because electrospun scaffolds imitate the extracellular matrix present in real tissues, they offer the perfect environment for tissue regeneration and cell proliferation in tissue engineering. Because of their high surface area and porosity, nanofiber mats are great options for filtering in a variety of applications, such as protective clothes and the purification of water and air. Because of their large surface area and interconnected porous structure, electrospun nanofibers have been investigated as electrode materials for batteries and supercapacitors in the field of energy storage7. These materials offer increased performance. Highly sensitive and responsive sensors for a range of analytes and environmental variables have also been developed as a result of the ability to integrate sensing elements onto nanofibers. Both societal demands and technical breakthroughs will fuel future developments in electrospinning. Adaptive materials and smart textiles that react to environmental changes are becoming possible because to the integration of stimuli-responsive elements into electrospun fibers. Moreover, a deeper comprehension of the structure-property correlations in nanofibers is made possible by the integration of electrospinning with nanotechnology and sophisticated characterization techniques, which results in more exact control over the properties and functionalities of the nanofibers8. With an emphasis on current developments, obstacles, and future possibilities, this short review article seeks to give an overview of the approaches and varieties of electrospinning technology. We aim to provide insights that will help researchers and industry experts fully utilize this flexible technology by looking at the basic concepts, materials, processing methods, and applications of electrospun nanofibers. Electrospinning is expected to be a key player in solving some of the most important problems in materials science, medicine, environmental conservation, and energy technology as it develops and finds new uses9.

Current Developments in Electrospinning

Recent years have witnessed major developments in electrospinning, a versatile technology that may be used to create nanofibers from a variety of materials. Its uses are numerous and include energy storage, filtration, medication delivery, tissue engineering, and more. Because electrospinning can produce nanoscale fibers with special qualities including high surface-area-to-volume ratios, porosity, and adjustable architectures, it is gaining popularity. These fibers have applications in a broad spectrum of cutting-edge technology, including environmental and healthcare solutions. Here are a few significant advancements in electrospinning:

1. Advances in Materials for Electrospinning

Current developments in electrospinning materials concentrate on creating functionalized nanofibers, composite fibers, and biodegradable polymers to improve performance in a range of applications. Tissue engineering and medication delivery are using more and more biodegradable materials because they offer safer, more environmentally friendly alternatives. Composite fibers with polymers and nanoparticles combine to provide multipurpose properties. These materials make it possible to build scaffolds, which are necessary for adhesions, growth, and differentiation10.

- Natural vs. Synthetic Polymers

Recent advances in electrospinning have primarily focused on the use of novel materials. The development of biodegradable and biocompatible polymers is especially intriguing for use in biomedical applications. In scaffolds for tissue engineering, polymers such as collagen, polylactic acid PLA, and polycaprolactone PCL are being used more and more10. Both synthetic and natural polymers are the two main materials used in electrospinning. Natural polymers including collagen, gelatin, chitosan, and silk fibroin have outstanding biocompatibility and biodegradability, making them useful for biomedical applications like tissue engineering and wound healing. However, there can be limitations to their mechanical strength and processability. On the other hand, synthetic polymers provide greater control over the fiber diameter, degradation rates, and mechanical properties. Examples of these polymers are polycaprolactone PCL, poly lactic-co-glycolic acid PLGA, and polyethylene oxide PEO. They frequently don't have the innate bioactivity of natural materials, though11. Collagen and PCL mixtures can yield fibers that are mechanically strong and biocompatible, which makes them great options for scaffolds used in tissue engineering. An analogous combination of silk fibroin and synthetic polymers, such as PLGA, has been shown to preserve good cell adhesion and growth while exhibiting improved mechanical properties and customizable breakdown rates. The progress in electrospinning has enabled these attempts to blend the two kinds of polymers11.

- Nanocomposites and Functional Materials

Nanocomposites, materials that integrate nanoscale additives such as nanoparticles, carbon nanotubes, or graphene, have significantly expanded the functional possibilities of electrospun fibers. These compounds improve properties such as electrical conductivity, mechanical strength, and thermal stability. Bioactive nanoparticles, including hydroxyapatite or bioactive glass, have been added to electrospun fibers in tissue engineering to enhance their osteoconductivity and suitability for bone regeneration applications. Likewise, regulated release of medicinal substances can be achieved through the construction of nanocomposites for drug delivery. This is very helpful in building scaffolds that administer drugs locally, eliminating the need for systemic administration12. In addition to traditional polymers, the electrospinning of conductive polymers such as polyaniline PANI or polypyrrole PPy is a recent advance. These conductive fibers have potential applications in biosensors, neural tissue engineering, and even smart clothing that can provide electrical stimulation to improve tissue healing.

- Multilayer Fibers

Another significant advancement in electrospinning is the production of core-shell and multilayered fibres. This involves electrospinning two or more materials together, with one forming the core and the other forming the fiber's shell. This method allows for the combining of materials with different characteristics in a single fibre. For example, a biodegradable polymer can serve as the shell, while a drug-loaded core allows for controlled release. This approach has found widespread use in drug delivery and tissue scaffolds, where the outside layer offers structural integrity while the interior delivers bioactive chemicals over time13. Core-shell fibres in drug delivery systems enable precise control over the release profile of encapsulated medicines. Depending on the material composition and fibre structure, this method can be tuned to produce either quick or prolonged release. Furthermore, in tissue engineering, core-shell architectures have been employed to imitate tissues' complex extracellular matrix ECM, resulting in improved cell adhesion, proliferation, and differentiation14.

- Multipurpose Fibers for Intelligent Materials

Another area of interest in electrospinning is the development of "smart" materials. Multifunctional fibers that respond to stimuli such as pH, temperature, and light have been created for advanced biomedical applications. These fibers can change shape, release medications, or change mechanical properties in response to external stimuli, making them excellent for use in dynamic situations such as wound healing or drug delivery.

For example, pH-sensitive fibers consisting of polymers such as poly2-diethylamino ethyl methacrylate PDEAEMA have been created for drug delivery applications in which drug release is triggered by the acidic environment of a wound or tumor. Similarly, temperature-sensitive polymers like poly-isopropyl acrylamide PNIPAM can be electrospun into fibers that shrink or swell in response to temperature changes, allowing for regulated drug delivery15. Scientists are also working on composite nanofibers, which blend several materials e.g., polymers and nanoparticles to obtain certain capabilities. For example, electrospun fibers doped with silver nanoparticles have antibacterial characteristics, making them suitable for wound dressings and surgical meshes16.

2. Innovative Techniques in Electrospinning

Traditional electrospinning setups have limitations when it comes to producing fibers in three-dimensional 3D structures or complex shapes. To address these challenges, 3D electrospinning has been developed, enabling the fabrication of thicker and more structured scaffolds suitable for tissue engineering. Additionally, co-axial electrospinning is gaining attention for producing core-shell fibers, where different materials are present in the core and the shell. These fibers are beneficial for controlled drug release or encapsulating sensitive biomolecules17.

- Coaxial Electrospinning Core-Shell Fibers

Coaxial electrospinning, also known as core-shell electrospinning, is one of the most significant innovations in electrospinning techniques. This method involves the use of two concentric needles, where one needle contains the core material and the other contains the shell material. When electrospun, the materials form a fiber with a distinct core-shell structure. This technique allows for the encapsulation of bioactive molecules, drugs, or nanoparticles within the core while providing a protective or functional shell18.

Applications of Coaxial Electrospinning:

Drug Delivery: The core-shell construction enables the regulated release of encapsulated pharmaceuticals. The outer shell can deteriorate at a specified rate, allowing for precise control over when the medicine is delivered.

Tissue Engineering:

Core-shell fibers can better imitate the extracellular matrix ECM by having a layered structure that promotes cell adhesion and proliferation.

Protective Coatings:

The core material may be vulnerable to external conditions, whereas the shell can protect it from degradation or give additional desirable qualities such as hydrophilicity or hydrophobicity.

- Emulsion Electrospinning

Emulsion electrospinning is another novel technology that has gained popularity in recent years. Rather than using a single polymer solution, this approach employs an emulsion a combination of two immiscible liquids. The emulsion can contain a variety of phases, including oil droplets or water-based solutions within a polymer matrix, allowing hydrophilic or hydrophobic substances to be encapsulated within the fibers19.

Advantages of Emulsion Electrospinning:

Encapsulation of Bioactive Compounds: Emulsion electrospinning is very beneficial in drug delivery applications because it allows for the encapsulation of hydrophobic and hydrophilic pharmaceuticals in various phases of the emulsion19.

Sustained Release:

The use of multiple phases can result in sustained release profiles, making this technique excellent for regulated drug administration over long periods19.

Environmental Advantages:

Emulsion electrospinning typically removes the need for hazardous organic solvents by utilizing water-based systems, making it a more ecologically friendly method19.

- Needleless Electrospinning

Traditional electrospinning uses a needle to extrude the polymer solution into fibers, but needleless electrospinning avoids the requirement for a nozzle by employing a revolving disk, wire, or cone structure. The polymer solution develops a thin coating on the surface, and the applied electric field causes numerous jets to be released, resulting in large quantities of nanofibers19.

Advantages of Needleless Electrospinning:

Scalability:

One of needleless electrospinning's main benefits is its scalability. It can produce nanofibers in large quantities, which makes it appropriate for use in industrial settings19.

Decreased Clogging:

When working with extremely viscous or complicated solutions, traditional needle-based devices are susceptible to nozzle clogging. This problem is reduced by needleless electrospinning, increasing operational effectiveness19.

Uniform Fiber Distribution:

The technique makes it possible for fibers to be distributed more evenly, which is crucial for applications where consistency is essential, such as filtration or sensor creation19.

- Multijet Electrospinning

In multijet electrospinning, many nozzles are used simultaneously to generate fibers. This technology increases production rates and allows multiple polymer solutions to be blended in real-time, resulting in fibers with a range of compositions and qualities1920.

Multijet Electrospinning Applications:

Composite Materials:

By passing different polymers through different nozzles, fibers with unique composite architectures can be created. It is beneficial to use this process to produce materials with higher mechanical strength, flexibility, or conductivity20.

Scalable Production:

Multijet electrospinning is designed for high-throughput production, just like needleless electrospinning. This is necessary to increase the production of nanofibers for industrial filters, wound dressings, and protective clothing, among other commercial uses20.

- Melt Electrospinning

Melt electrospinning removes the need for solvents by heating the polymer to its melting point prior to electrospinning it into fibers. Conventional electrospinning frequently uses solvent-based solutions. This process works better for creating fibers from thermoplastic polymers and is also more ecologically friendly21.

Melt electrospinning benefits

No Solvent Residue:

This is crucial for biomedical applications since there is no need to worry about solvent residues in the finished product because there isn't any used. Environmental Impact: Melt electrospinning is less detrimental to the environment and human health than other methods because it does not require the use of hazardous solvents22.

Customization of Fiber Properties:

By modifying the temperature and rate at which polymer melts, fiber characteristics may be precisely controlled, providing increased authority over the morphology and mechanical properties22.

- Electrospinning with External Fields

Utilizing outside fields to affect the fiber creation process—such as magnetic or acoustic field is another cutting-edge method of electrospinning. These fields can be applied to induce specific functions in the fibers, alter the pattern of deposition, or align the fibers23.

Examples of External Field Applications:

Magnetic Field:

Electrospun fibers can be aligned by magnetic fields to form more ordered structures. This is useful for tissue engineering applications because aligned fibers can direct cell proliferation23.

Acoustic Field:

The spatial distribution of fibers has been manipulated by acoustic waves, enabling more accurate placement of fibers in electronic or sensor systems24. Moreover, a technique to boost manufacturing rates is needleless electrospinning. Large-scale manufacture of nanofibers is made possible by this process, which differs from traditional single-needle electrospinning in that it generates numerous jets concurrently using a rotating disk or wire24.

3. Applications in Healthcare and Medicine

Regenerative medicine is one of the most promising fields for electrospinning. The extracellular matrix ECM of natural tissues is mimicked by electrospun scaffolds, which encourages tissue regeneration and cell proliferation. Researchers have successfully constructed scaffolds for skin, bone, cartilage, and nerve regeneration using electrospinning. Electrospun scaffolds are the perfect tool for customizing mechanical and biological features to match the demands of different tissues because of the exquisite control over fiber shape and porosity.

Fig.1 Applications of Electrospinning

V. V. Pongade*

V. V. Pongade*

Iraa Gupta

Iraa Gupta

Prathamesh C. Rumde

Prathamesh C. Rumde

Sridhar Satyabhushanam Vannam

Sridhar Satyabhushanam Vannam

10.5281/zenodo.14000605

10.5281/zenodo.14000605