Nanotechnology has revolutionized various fields owing to the unique properties exhibited by nano materials. Green synthesis methods have garnered significant attention due to their eco-friendly nature and potential applications across diverse domains. This review provides an overview of recent advancements in the green synthesis of nano materials and explores their multifaceted applications. A comprehensive analysis of various green synthesis techniques and their applications is presented, focusing on the synthesis of nano particles using biological entities such as plants, fungi, and bacteria. Furthermore, the review discusses the characterization techniques employed to evaluate the properties of green-synthesized nanomaterials. The diverse applications of these nanomaterials, including catalysis, environmental remediation, biomedical applications, and antibacterial activity, are also highlighted. Additionally, recent research trends and future prospects in the field of green nanotechnology are discussed.

Green synthesis, Nanomaterials, Nanoparticles, Sustainable synthesis, Biological synthesis, Plant-mediated synthesis, Microbial synthesis, Agricultural waste biomass, Biocompatibility, Toxicity assessment, Surface functionalization, Scale-up, Commercialization, Life cycle assessment (LCA),Environmental impact, Biomedical applications, Catalysis, Characterization techniques, Regulatory compliance, Future perspectives

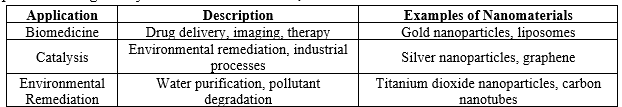

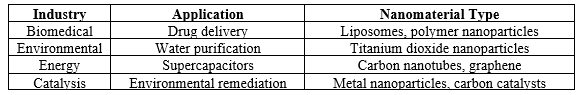

Nanotechnology has evolved rapidly over the past few decades, offering innovative solutions to a wide range of challenges in areas such as healthcare, energy, environmental remediation, and electronics. Nanomaterials, characterized by their unique properties at the nanoscale, have garnered significant interest due to their potential for revolutionizing various industries. However, traditional methods of synthesizing nanomaterials often involve the use of hazardous chemicals, high energy inputs, and generate toxic by-products, posing environmental and health risks. In response to these concerns, researchers have increasingly focused on developing green synthesis methods that utilize natural resources and eco-friendly processes for the fabrication of nanomaterials. Green synthesis offers several advantages over conventional approaches, including reduced environmental impact, lower energy consumption, biocompatibility, and scalability. By harnessing the reducing and stabilizing properties of natural sources such as plants, microorganisms, and agricultural waste biomass, green synthesis methods enable the production of nanomaterials with tailored properties for specific applications.

Green Synthesis Methods

Green synthesis methods encompass a variety of approaches, each utilizing different biological or natural entities for the fabrication of nanomaterials.

- Plant-Mediated Synthesis:

Plant-mediated synthesis involves the use of plant extracts or biomasses as reducing and stabilizing agents for the synthesis of nanoparticles. Various plant species, including medicinal herbs, fruits, and flowers, have been explored for their potential in nanoparticle synthesis. The bioactive compounds present in plant extracts, such as phenolic compounds, flavonoids, and terpenoids, play crucial roles in the reduction of metal ions and stabilization of nanoparticles. The synthesis process is typically carried out under mild reaction conditions, avoiding the need for high temperatures or toxic chemicals.

- Microbial-Mediated Synthesis:

Microorganisms, including bacteria, fungi, and algae, have been utilized for the green synthesis of nanoparticles. Microbial cells or their extracellular metabolites act as reducing agents, facilitating the conversion of metal ions into nanoparticles. Fungi such as Rhizopus stolonifer, bacteria like Bacillus subtilis, and algae species have demonstrated potential for synthesizing nanoparticles with controlled sizes and shapes. Microbial-mediated synthesis offers advantages such as rapid synthesis rates, scalability, and versatility in nanoparticle composition.

- Agricultural Waste Biomass-Derived Synthesis:

Agricultural waste biomass, including crop residues, food processing by-products, and plant biomass, can serve as sustainable sources for nanoparticle synthesis. The rich organic content of agricultural waste biomass provides abundant reducing agents for the fabrication of nanoparticles. Common biomass feedstocks include rice husk, sugarcane bagasse, coconut shells, and corn cobs. Through pyrolysis, hydrothermal treatment, or chemical activation, agricultural waste biomass can be converted into carbon-based materials suitable for various applications, including energy storage, catalysis, and environmental remediation.

Mechanisms of Green Synthesis

Understanding the underlying mechanisms of green synthesis methods is essential for optimizing synthesis conditions and controlling the properties of synthesized nanoparticles. The mechanisms involved in green synthesis processes vary depending on the biological or natural entities used and the specific reaction conditions. However, common mechanisms include:

- Reduction of Metal Ions:

The reduction of metal ions to form nanoparticles is the key step in green synthesis methods. Biological entities such as plant extracts, microbial cells, and biomolecules act as reducing agents, donating electrons to metal ions, leading to their reduction and subsequent nanoparticle formation. The choice of reducing agent, reaction pH, temperature, and metal ion concentration influence the rate and extent of nanoparticle synthesis.

- Stabilization and Growth Control:

Following nucleation and nanoparticle formation, the stabilization of nanoparticles is critical to prevent agglomeration and ensure colloidal stability. Biomolecules present in biological extracts or microbial metabolites serve as capping agents, adsorbing onto nanoparticle surfaces and preventing their aggregation. The composition and concentration of stabilizing agents affect the size, shape, and dispersibility of synthesized nanoparticles. Additionally, the kinetics of nanoparticle growth can be controlled through modulation of reaction parameters, allowing for the synthesis of nanoparticles with desired properties.

- Biomineralization and Templated Synthesis:

In some cases, biological entities facilitate nanoparticle synthesis through biomineralization processes or templated synthesis mechanisms. Biomolecules such as proteins, enzymes, and polysaccharides act as templates or scaffolds, guiding the nucleation and growth of nanoparticles with specific crystalline structures and morphologies. Biomineralization processes mimic natural mineralization pathways found in organisms, leading to the formation of biomimetic nanomaterials with tailored properties for biomedical, catalytic, and environmental applications.

Comparison with Conventional Synthesis Methods

Green synthesis methods offer several advantages over conventional chemical and physical methods for nanoparticle synthesis. A comparative analysis of these approaches highlights the unique benefits of green synthesis, including:

Environmental Sustainability:

Green synthesis methods utilize renewable resources and eco-friendly processes, minimizing the generation of hazardous waste and reducing environmental pollution. In contrast, conventional methods often involve the use of toxic chemicals, solvents, and high-energy inputs, leading to environmental degradation and resource depletion.

Biocompatibility and Safety:

Green-synthesized nanoparticles exhibit enhanced biocompatibility and reduced toxicity compared to nanoparticles synthesized using conventional methods. The absence of residual chemicals and contaminants in green-synthesized nanoparticles reduces the risk of adverse effects on human health and the environment, making them suitable for biomedical and environmental applications.

Cost-Effectiveness and Scalability:

Green synthesis methods offer cost-effective and scalable routes for nanoparticle production, utilizing inexpensive raw materials and simple reaction conditions. The abundance of natural sources such as plants, microorganisms, and agricultural waste biomass enables large-scale synthesis of nanoparticles at low cost, facilitating their commercialization and widespread adoption in various industries.

Control over Nanoparticle Properties:

Green synthesis methods provide greater control over the size, shape, composition, and surface properties of synthesized nanoparticles compared to conventional methods. By optimizing reaction parameters and selecting appropriate biological or natural entities, researchers can tailor the properties of nanoparticles to meet specific application requirements, such as catalysis, sensing, drug delivery, and environmental remediation.

Biocompatibility and Toxicity Assessment

Assessing the biocompatibility and potential toxicity of green-synthesized nanoparticles is crucial for ensuring their safe and effective use in biomedical and environmental applications. Several factors influence the biocompatibility and toxicity of nanoparticles, including their size, shape, surface chemistry, and surface charge. Common techniques for evaluating nanoparticle biocompatibility and toxicity include:

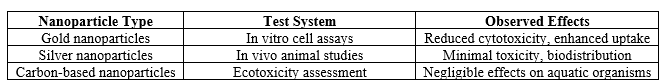

In Vitro Cell Studies:

Cell-based assays are commonly used to assess the cytotoxicity, genotoxicity, and immunotoxicity of nanoparticles using cultured cell lines. Various cell viability assays, such as MTT assay, LDH release assay, and live/dead staining, provide quantitative measures of cell viability and membrane integrity following exposure to nanoparticles. Additionally, techniques such as flow cytometry and fluorescent microscopy enable the evaluation of nanoparticle uptake, intracellular localization, and cellular responses.

In Vivo Animal Studies:

Animal models, including rodents, zebrafish, and non-human primates, are utilized to assess the biodistribution, pharmacokinetics, and toxicity of nanoparticles in vivo. Histopathological analysis, blood chemistry assays, and imaging techniques such as MRI, PET, and CT imaging enable the visualization and characterization of nanoparticle interactions with biological tissues and organs. Long-term studies are essential for evaluating the systemic effects and potential accumulation of nanoparticles in vivo.

Ecotoxicity Assessment:

Assessing the environmental impact of nanoparticles is critical for understanding their fate, behavior, and potential ecological risks. Ecotoxicity assays using aquatic organisms, such as algae, daphnia, and fish, provide insights into the effects of nanoparticles on freshwater and marine ecosystems. Parameters such as survival, growth, reproduction, and biomarker responses are monitored to assess the toxicity of nanoparticles to aquatic organisms and the overall ecosystem health.

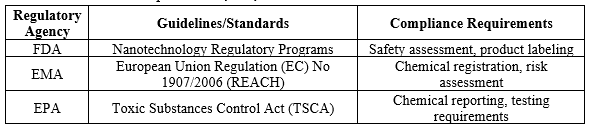

Risk Assessment and Regulation:

Integrating biocompatibility and toxicity data into risk assessment frameworks facilitates the identification of potential hazards and the development of regulatory guidelines for nanoparticle-based products. Regulatory agencies such as the US Food and Drug Administration (FDA), the European Medicines Agency (EMA), and the Environmental Protection Agency (EPA) oversee the safety evaluation and approval of nanomaterials for medical, pharmaceutical, and environmental applications. Risk assessment models, such as hazard identification, dose-response assessment, exposure assessment, and risk characterization, inform decision-making and regulatory policies regarding nanoparticle use and disposal.

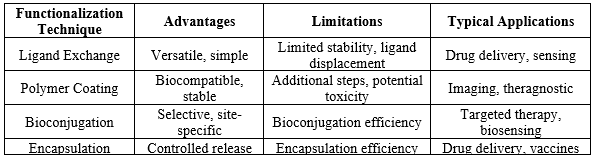

Surface Functionalization and Modification

Surface functionalization and modification strategies play a crucial role in tailoring the properties and enhancing the performance of green-synthesized nanoparticles for specific applications. Surface modification involves the attachment of functional groups, biomolecules, polymers, or nanoparticles onto nanoparticle surfaces to impart desired functionalities, such as targeting specificity, biocompatibility, stability, and controlled release. Common surface modification techniques include:

Ligand Exchange:

Ligand exchange involves the replacement of surface ligands or capping agents on nanoparticles with desired functional groups or biomolecules. Thiol-containing molecules, such as mercaptoalkanoic acids and thiolated polymers, are commonly used for ligand exchange reactions, forming stable covalent bonds with metal nanoparticle surfaces. Ligand exchange facilitates the introduction of functional groups such as carboxyl, amino, and hydroxyl groups, enabling further chemical modification and conjugation with targeting ligands, drugs, or imaging agents.

Polymer Coating:

Polymer coating provides a versatile and biocompatible approach for surface modification of nanoparticles, enhancing their stability, solubility, and biocompatibility. Amphiphilic polymers, such as polyethylene glycol (PEG) and polyvinyl alcohol (PVA), form hydrophilic shells around nanoparticles, preventing aggregation and opsonization in biological fluids. Polymer-coated nanoparticles exhibit prolonged circulation time, reduced immunogenicity, and enhanced cellular uptake, making them suitable for drug delivery, imaging, and theranostic applications.

Bioconjugation:

Bioconjugation involves the covalent attachment of biomolecules, such as antibodies, peptides, aptamers, and enzymes, onto nanoparticle surfaces for targeted delivery and sensing applications. Functionalized nanoparticles can selectively bind to specific molecular targets, such as cancer cells, pathogens, or biomarkers, enabling site-specific delivery of therapeutic agents or detection of disease-related biomolecules. Bioconjugation strategies include carbodiimide-mediated coupling, maleimide-thiol chemistry, and click chemistry reactions, ensuring stable and selective binding between nanoparticles and biomolecules.

Encapsulation and Encapsulation: Encapsulation and encapsulation techniques involve the encapsulation of nanoparticles within polymeric or lipid-based carriers to protect them from degradation, enhance their stability, and control their release kinetics. Nanoparticle-loaded carriers, such as liposomes, micelles, and nanoparticles, provide controlled release of therapeutic agents, imaging contrast agents, or vaccines, improving their efficacy and minimizing off-target effects. Encapsulation and encapsulation strategies enable the design of multifunctional nanoplatforms for drug delivery, imaging, and combination therapy applications.

Scale-Up and Commercialization Challenges

Scaling up green synthesis methods for industrial production and commercialization presents several challenges related to reproducibility, scalability, quality control, and regulatory compliance. Key considerations for scale-up and commercialization of green-synthesized nanoparticles include:

Reproducibility and Batch-to-Batch Variability:

Achieving consistent nanoparticle quality and performance across multiple production batches is essential for industrial-scale manufacturing. Variability in raw materials, reaction conditions, and process parameters can affect nanoparticle properties, leading to batch-to-batch variability and inconsistent product quality. Standardization of synthesis protocols, quality control measures, and process optimization are critical for ensuring reproducibility and reliability in large-scale production.

Scalability and Production Efficiency:

Scaling up green synthesis methods from laboratory-scale to industrial-scale production requires optimization of reaction parameters, reactor design, and process automation. Challenges such as heat and mass transfer limitations, mixing efficiency, and reactor fouling must be addressed to maximize production efficiency and minimize production costs. Continuous-flow reactors, microfluidic systems, and high-throughput screening techniques offer potential solutions for enhancing scalability and throughput in nanoparticle manufacturing.

Quality Control and Product Characterization: Quality control measures, including in-process monitoring, product testing, and characterization, are essential for ensuring the consistency, purity, and safety of green-synthesized nanoparticles. Robust analytical techniques, such as spectroscopy, microscopy, chromatography, and particle sizing, enable comprehensive characterization of nanoparticle properties, including size distribution, morphology, composition, and surface chemistry. Implementation of quality management systems and adherence to regulatory standards facilitate compliance with quality control requirements and regulatory guidelines for nanoparticle-based products.

Regulatory Compliance and Market Acceptance:

Regulatory approval and market acceptance of green-synthesized nanoparticles depend on their safety, efficacy, and compliance with regulatory requirements. Regulatory agencies, such as the FDA, EMA, and EPA, oversee the approval and registration of nanoparticle-based products for medical, pharmaceutical, and environmental applications. Comprehensive safety assessments, preclinical studies, and clinical trials are necessary to demonstrate the safety and efficacy of green-synthesized nanoparticles and obtain regulatory approval for commercialization. Public perception, consumer awareness, and market demand also influence the acceptance and adoption of green nanotechnology products, highlighting the importance of education, communication, and stakeholder engagement in promoting sustainable and responsible innovation.

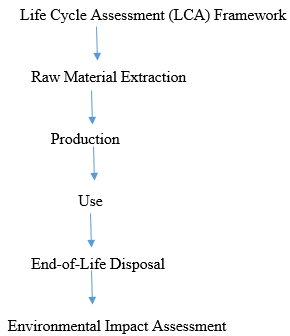

Life Cycle Assessment (LCA) and Sustainability Metrics

Life cycle assessment (LCA) is a systematic framework for evaluating the environmental impacts and sustainability of green-synthesized nanoparticles throughout their life cycle, from raw material extraction to end-of-life disposal. LCA considers various environmental indicators, such as energy consumption, greenhouse gas emissions, water usage, land use, and toxicity potential, to quantify the overall environmental footprint of nanoparticle production and use. Sustainability metrics, such as carbon footprint, water footprint, and ecological footprint, provide quantitative measures of sustainability performance and guide decision-making toward more sustainable and environmentally friendly practices.

Key components of LCA and sustainability assessment for green-synthesized nanoparticles include:

Inventory Analysis:

Inventory analysis involves compiling data on resource inputs, energy consumption, emissions, and waste generation associated with nanoparticle production processes. Raw material extraction, transportation, synthesis, purification, and packaging are considered in the inventory analysis to quantify the environmental burdens and resource consumption associated with nanoparticle manufacturing.

Impact Assessment:

Impact assessment evaluates the environmental impacts of nanoparticle production and use across various impact categories, including global warming potential, acidification potential, eutrophication potential, and human toxicity potential. Life cycle impact assessment (LCIA) methods, such as ReCiPe, IMPACT2002+, and USEtox, are utilized to quantify the environmental impacts of nanoparticle production and compare alternative production scenarios.

Interpretation and Improvement:

Interpretation of LCA results involves analyzing the environmental hotspots, identifying opportunities for improvement, and informing decision-making to minimize environmental impacts and enhance sustainability performance. Strategies for improving the sustainability of green-synthesized nanoparticles may include optimizing synthesis processes, reducing energy consumption, minimizing waste generation, and adopting green chemistry principles. Stakeholder engagement and collaboration are essential for implementing sustainability initiatives and fostering continuous improvement in nanoparticle manufacturing practices.

Certification and Eco-labeling:

Certification schemes and eco-labeling programs provide assurance to consumers and stakeholders regarding the environmental performance and sustainability credentials of green-synthesized nanoparticles. Third-party certification bodies, such as the International Organization for Standardization (ISO), Green Seal, and Cradle to Cradle, certify products based on their compliance with environmental criteria and sustainability standards. Eco-labels, such as Energy Star, USDA Organic, and EcoLogo, help consumers make informed choices and support sustainable purchasing decisions.

Emerging Trends and Future Directions

The field of green nanotechnology continues to evolve, driven by emerging trends, technological advancements, and interdisciplinary collaborations. Key emerging trends and future directions in green nanotechnology include:

Advanced Synthesis Techniques:

Advancements in synthesis techniques, such as microwave-assisted synthesis, ultrasound-assisted synthesis, and hydrothermal synthesis, enable rapid, efficient, and scalable production of green-synthesized nanoparticles with enhanced properties and functionalities. Innovative approaches, such as bioreactor systems, continuous-flow reactors, and microfluidic platforms, offer opportunities for process intensification and automation in nanoparticle manufacturing.

Multifunctional Nanomaterials:

Multifunctional nanomaterials, combining therapeutic, diagnostic, and theranostic functionalities, are emerging as promising platforms for precision medicine, personalized healthcare, and targeted therapy. Green-synthesized nanoparticles can be engineered to deliver therapeutic agents, imaging contrast agents, and targeting ligands simultaneously, enabling synergistic effects and improved treatment outcomes in complex diseases such as cancer, cardiovascular disorders, and infectious diseases.

Smart Nanomaterials and Responsive Systems: Smart nanomaterials with stimuli-responsive properties, such as pH-responsive, temperature-responsive, and light-responsive behavior, offer dynamic control over drug release, imaging contrast, and therapeutic efficacy. Green-synthesized nanoparticles can be designed to respond to specific environmental cues or external stimuli, enabling triggered release of therapeutic payloads, on-demand imaging, and site-specific targeting in vivo.

Sustainable Manufacturing Practices: Sustainable manufacturing practices, such as green chemistry principles, eco-friendly solvents, and renewable energy sources, are integral to the development of green nanotechnology solutions with minimal environmental impact. Green synthesis methods that utilize non-toxic reagents, water-based solvents, and energy-efficient processes contribute to resource conservation, pollution prevention, and sustainability in nanoparticle manufacturing.

Cross-Disciplinary Collaborations:

Cross-disciplinary collaborations between researchers, engineers, clinicians, and policymakers facilitate innovation, knowledge exchange, and technology transfer in green nanotechnology. Collaborative research initiatives address complex challenges at the interface of nanoscience, biology, medicine, and environmental science, leading to transformative solutions with societal impact. Public-private partnerships, academic-industry collaborations, and international consortia promote synergies and accelerate the translation of research findings into practical applications and commercial products.

Regulatory Compliance and Policy Support: Regulatory compliance and policy support are critical for fostering the responsible development, deployment, and commercialization of green nanotechnology products. Regulatory agencies play a key role in assessing the safety, efficacy, and environmental impact of green-synthesized nanoparticles and establishing guidelines for their production, labeling, and marketing. Policy frameworks, such as nanomaterial regulations, product stewardship programs, and green procurement policies, promote transparency, accountability, and sustainability in the nanotechnology sector, ensuring the responsible use and management of nanomaterials throughout their life cycle.

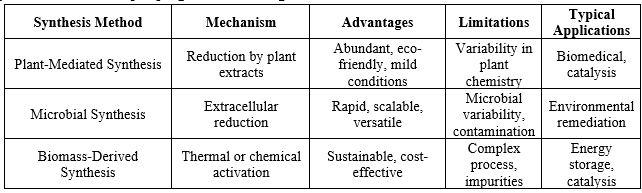

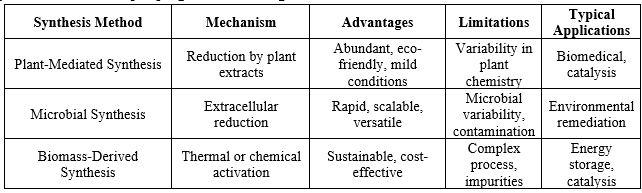

Tabular Form: Comparison of Green Synthesis Methods

This table could compare different green synthesis methods (e.g., plant-mediated synthesis, microbial synthesis, agricultural waste biomass-derived synthesis) based on parameters such as synthesis mechanism, advantages, limitations, and typical applications.

Prasanna Babu Racheeti* 1

Prasanna Babu Racheeti* 1

Y. Ramya 2

Y. Ramya 2

10.5281/zenodo.10853399

10.5281/zenodo.10853399