Abstract

The operating procedure of equipment used in formulation and evaluation in cosmetics industry is covered in this manuscript. It covers handaling, risk management, requirements, standard and maintainace of equipment as well as is benefit and purpose, desinging SOPs and procedures. Weinging balance, Microscope, PH meter, Brookfield viscometer, UV spectrometer, Homogenizer and Soxhlet apparatus are among the equipmet discussed. This review manuscript explore the outlining the SOPs accontabilities, preparation, procedure, operation and application, as well as the obejectives behind their creation and the safe and efficient operation of any process to ensure that the procedures are carried out correctly and in order.

Keywords

Standard Operating Procedure, SOP format, Equipments, Overview.

Introduction

A Standard Operating Procedure (SOP) is a set of step-by-step instructions that outline how to perform a routine task or activity. SOPs are used to ensure that task are completed consistently and in compliance with industry regulations and business standards. SOPs are utilized in various contexts by a vast array of entities, including those in the areas of business, education, government, health care, industry, and the military. Although categorical variations are inevitable, all SOPs have in common the systematization of the individual steps performed in the implementation of a repetitive task to create an overall quality system. SOPs first identify and summarize a task, describe its purpose, and specify when and by whom it is to be performed while simultaneously defining uncommon or specialized terms and addressing potential concerns (e.g., necessary equipment or supplies, health and safety cautions, etc.). They then describe the sequential procedures to be followed, often utilizing activity checklists and graphic illustrations (e.g., charts, tables, photographs, diagrams, etc.) to help ensure that the procedures are being performed accurately and in order.SOPs can also provide many other benefits, such as minimizing the chance of miscommunication, affording comparability, and ensuring regulatory compliance. However, they must be periodically assessed and modified to maintain currency, thus enabling them to further improve final results. The disadvantages of SOPs include excessive paperwork and a reduction in workplace individuality.

Process of SOP:

Objective of SOP:

- Ensure Proper Instrument Handling: Understand and implement SOP guidelines for safe, accurate and efficient use of lab instrument.

- Maintain Quality and Compliance: Adhere to SOP standards to uphold regulatory requirements and ensure product quality.

- Enhance Safety and Efficiency: Apply safety protocols to reduce risk associated with instrument handling and streamline lab operations.

Benefits of SOP:

Application of SOP :

- Training: SOPs help train new employees and existing employ on new tasks, procedures, or equipment.

- Consistency: SOPs help ensure that tasks are performed consistently, safely, and to a high standard, regardless of who does them.

- Quality: SOPs help maintain the quality of output and service.

- Safety: SOPs help incorporate safety standards into routine operations.

- Regulatory compliance: SOPs help ensure that regulatory compliance standards are met.

- Environmental impact: SOPs help certify that procedures don't negatively impact the environment.

- Problem solving: SOPs can be used as a go-to guide for solving problems.

- Types of SOP :

1. Step-by-Step SOPs: Provide a sequential order of tasks that need to be completed.

2. Hierarchical SOPs: Handle processes that require a complex series of steps with sub-step.

3. Checklist SOPs: Ensure that all the nessary steps or items are completed or verified.

4. Flowchart SOPs: Represent processes visually showing the sequence of actions , desion points , and potential outcomes.

5. Simple SOPs: Provide straight forward instructions for tasks that are simple and required little the explation .

6. Quality Assurence (QA) SOPs: Maintain consistency and quality in products or services.

- Administrative SOPs: Standardize routine administrative tasks within an organization.

- Formats for Standard Operating Procedure:

Designing of SOP: When creating the SOP Considerd arc the following points.

Objective: Establish a processes for creating standard operating procedure.

Scope: The SOPs are used by the entire organisation must follow these method.

Responsibility: Person performing: The relevant HODs for the relavent department QA officer .

- Procedure:

1. Body:

2. Header:

3. Signature block

- Sop Of Equipments: Formulation And Evaluation -

1. Weighing balance

2. Microscope

3. PH meter

4. Brookfield viscometer

5. UV spectroscopy

6. Homogenizer

7. Soxhlet appratus

1.Title: Standard Operation For Operation & Cleaning Of Electronic Digitl Balance

1.Purpose

To describe the procedure for operation & cleaning of electronic digital balance

2.Scope

This SOP is applicable for operation & cleaning of Electronic Digital Balance at P. R. Patil Institute of Pharmacy.

3.Responsibility And Accountability

Preparation

SOP shall be prepared by the authorized person. Initiator of the SOP shall ensure that the contents of SOP are well understood by the all operating person and student. Initiator shall be responsible to ensure the technical content with respect to operations, process, as mentioned in the SOP

Review

Reviewer shall be responsible to ensure the technical content with respect to operations.

Approval

Principal /HOD/designee shall be responsible for approval and implementation of SOP

Procedure

Precaution

Handle with care

Operation:

Check power supply of the weighing balance

Press ON/OFF switch of balance to turn on the weighing balance

Please assure that weighing balance calibrated.

Before start the weighing balance please assure zero is displayed if not please press

Place the suitable container in which sample is to be measure & after press tare key.

The balance shall display 0.000.

Add the sample till you get desired weight on display & allow stabilizing the reading. After getting the stable display take out the sample with container.To study the SOP for handling of equipments

Press tare key again and switch of the weighing balance.

Cleaning:

Clean with dry clean cotton cloth

Fig : Electronic Digital Balance

2. Title:- Standard Operating Procedure For Operation & Cleaning Of Microscope.

1.Purpose

To describe the Procedure for operation & cleaning of Microscope.

2.Scope

This SOP for operation & cleaning of Microscope at P. R. Patil Institute of Pharmacy.

1.Responsibility And Accountability

Preparation

SOP shall be prepared by the authonzed person Initiator of the SOP shall ensure that the contents of SOP are well understood by the all operating person and student. Initiator shall be responsible to ensure the technical content with respect to operations, process, as mentioned in the SOP Initiator shall refer all documents as applicable while preparing the SOP.

Review

Reviewer shall be responsible to ensure the technical content with respect to operations.

Approval

Principal /HOD/designee shall be responsible for approval and implementation of SOP.

1.Procedure

Precaution

Handle with care

Operation

Switch on the instrument by using ON/OFF switch. The green LED integrated ON/OFF switch lights up, to indicate that the instrument is ready for operation. Set the required brightness through brightness control. Position the slide on the stage with the sample to be observed on the upper surface of the slide Adjust the slide to bring into the exact center of the light source.

Low magnification objective lens shall be focussed first followed by high magnification lens on the center of the sample.Term the coarse adjustment knob to adjust the stage. White observing through the ocular bring the object into focus try adjusting with the coane knob. Easily using fine adjustment knot, focus the sample for better resolution.

Adjust the diaphragm lever to reduce or increase the light intensity to produce the clear and sharp image. Once the image is visible, adjust the slide for the targeted item in the image To proceed from low power to high power magnification, rotate the high power objective into position.

Fig: Parts of Microscope

3.Title:- Standard Operating Procedure For Operation And Cleaning Of Ph Meter.

1.Purpose

To describe the Procedure fur operation & chanting of Digital PH meter.

2. Scope

The SOP applicable for operation & chaning of Digital PP Pharmacy.

3.Responsibility And Accountability

Preparation SOP shall be prepared by the authorized person, Initiator of the SOP shall ensure that the contents of SOP are well understood by the all operating person and student Initiator shall be responsible to ensure the technical content with respect to operations, process as mentioned in the SOP. Initiator shall refer all documents as applicable while preparing the SOP

Review

Reviewer shall be responsible to ensure the technical content with respect to operations.

Approval

Principal /HOD/designee shall be responsible for approval and implementation of SOP.

4. Procedure

Precaution

The electrode always be immersed in the electrode buffer (Before and after use) DO NOT rub the membrane of the electrode The instrument not be used to measure pH of viscous solutions.

Operation

Switch on the instrument

Remove the electrode dipped in electrode buffer.

Rinse with distilled water.

Dry the outer surfaces of the electrode with a clean dry tissue

Dip electrode in solution whose pH has to be measured.To study the SOP for handling of equipments

After use rinse the electrode in distilled water, dry and dip the electrode back in the electrode buffer.

Switch off the instrument after use.

Cleaning:

Clean with dry clean cotton cloth.

Fig: Electronic PH Meter

4. Title:- Standard Operating Procedure Operation & Cleaning Of Brookfield Viscometer.

1.Purpose:

To provide a procedure for the operating of Brookfield Viscometer apparatus

2.Scope:

Applicable to operation of Brookfield Viscometer apparatus.

3. References: -

Instrument Manual

Safety Issues and Precautions: Were Head cap, Mask, Hand glows and other safety requirements during the performance of stated activity. Please make the entry of Usage with require details in the Instrument log book. Handle the Instrument properly with care. After using the apparatus please clean the instrument and accessories and keep it Clean.

4. Procedure: Turn on the viscometer and allow standing, must be auto zero, after the few seconds the screen appears which indicates 2 digits.

Now press the key, the screen displays to remove spindle, after removing the spindle and pressing the key the instruments beings, it is auto zeroed.

After approximately 15 see, the screen displays the instruction to replace spindle.

Attach the spindle to viscometer by screwing then on the lower shaft using left hand thread.

Press the spindle key and up and down arrow keys. When the desired code is displayed release the arrow key.

To select spindle, first press either up and down key which cause the area to show current speed, press the set speed key for adjusting the speed.

Insert center of this spindle in the test material until the fluid level is at the To study the SOP for handling of equipments

Immersion groove on the spindle shaft. Tilt the spindle slightly while immersing to avoid air entrapment. To measure high viscosity choose a small spindle and to slow speed if the chosen spindle/speed result in torque above 1 00% and then reduce the value.

Allow time for the individual reading to stabilize, record the value.

Press the motor on/off/escape key to turn off motor.

The time mode allows the user to record the reading for fixed period of time or until a set torque value is attained.

Then enter/auto turnkey allows determining maximum calculated viscosity possible with current spindle/speed.

Pressing the up and down arrow keys will allow the viscometer data to be examine, pressing and other key( except enter/press key) will bring back normal display.

Turn off the mains after use.

Fig: Brookfield Viscometer

3.Title:- Standrad Operating Procedure For Operation & Cleaning Of Uv Spectroscopy.

1.Purpose

To describe the Procedure for operation & cleaning of UV-VIS Spectrophotometer

2. SCOPE

This SOP in applicable for operation & cleaning of UV-vis spectrophotometer at P R Patil institute of pharmacy.

3. Responsibility And Accountability

Preparation

SOP shall be prepared by the authorized person

Initiator of the SOP shall ensure that the contents of SOP are well understood by the all operating person and student.

Inimator shall be responsible to ensure the technical content with respect to operations, process, as mentioned in the SOP Initiator shall refer all documents as applicable while preparing the SOP

Review

Reviewer shall be responsible to ensure the technical content with respect to operations

Approval

Principal /HODldesignee shall be responsible for approval and implementation of SOP

3.Procedure

4.Introduction

Ultraviolet-Visible spectroscopy, is a powerful analytical technique used to study the absorption of light by substances. This spectroscopic method measures the absorption of ultraviolet and visible light wavelengths in the electromagnetic spectrum

Precaution

Warm-up for 30 minutes or longer after power on

Do not open sample compartment during initialization

Do not open sample compartment during baseline correction. Auto zero and sampling

measurement mode

Before placing the cuvettes in the sample holder, clean the outer surface of the cuvettes of

with tissue paper.

Do not hold the cuvettes from its transprant optical surface.To study the SOP for handling of equipments.

Warm-up for 30 mins or longer after power on.

Operation

During initial confirm that nothing is placed in the sample compartment and cell holder.

Press “I” on the power switch. The power istmed "ON" The screen to display initialization

tenis appears and initialization anu check are performed sequentially.

After initialization of each item the mode menu appears.

Select the following three measurments modes.

Fig : UV -Visible Spectroscopy

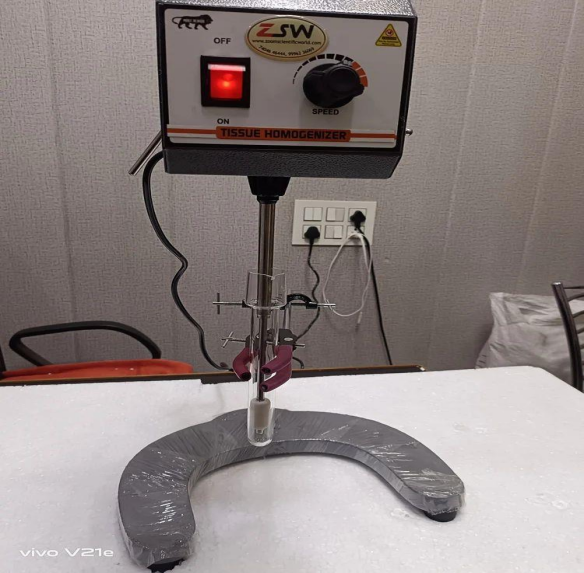

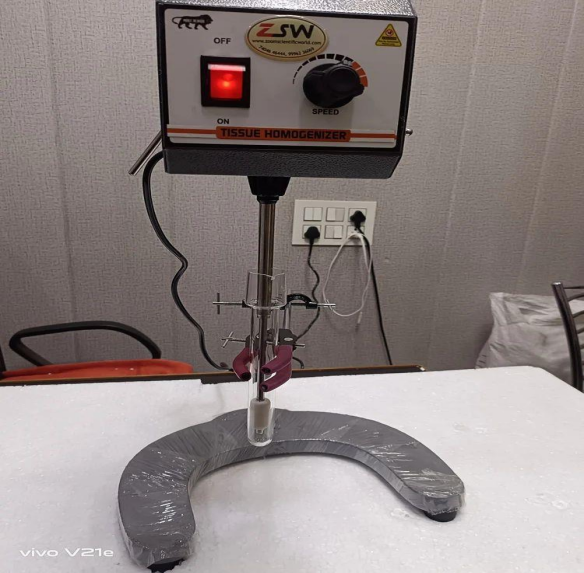

6.Title :- Standard Operating Procedure For Operating & Cleaning Of Homogenizer.

1.Purpose

To describe the Procedure for operation & cleaning of Homogenizer.

- Scope

This SOP is applicable for operation & cleaning of Homogenizer at P. R. Patil institute of pharmacy.

Responsibility And Accountability

Preparation

SOP shall be prepared by the authorized person.

Initiator of the SOP shall ensure that the contents of SOP are well understood by the all operating person and student.

Initiator shall be responsible to ensure the technical content with respect to operations, process, as mentioned in the SOP.

Initiator shall refer all documents as applicable while preparing the SOP.

Review

Reviewer shall be responsible to ensure the technical content with respect to operations.

Approval

Principal /HOD/designee shall be responsible for approval and implementation of SOP.

4. Procedure

Precaution

Handle the Instrument properly with care.

Operation

Connect the plug into the socket.

Fix the homogenizer apparatus.

Turn on the apparatus by the power button. Adjust the speed rate (RPM) by bottom and top arrows Enter the specific probe into the first hole on the beam of the probe into the liquid which requires to be homogenized.

After usage turn off the apparatus.

Cleaning:

Clean the apparatus after use by wash the probe with water after that 70% ipa finally rinse with purified water.

Fig: Homogenizer

3.Title:- Standard Operating Procedure For Operation And Cleaning Of Soxhlet Appratues.

1.Purpose:

To provide a standardized method for operating and maintaining the Soxhlet apparatus to ensure the efficient and safe extraction of compounds from solid materials.

2. Scope:

This SOP applies to all personnel involved in the use of the Soxhlet apparatus in the laboratory for extraction purposes.

3. Responsibility:

Laboratory Technicians: Operate the Soxhlet apparatus as per the SOP.

Lab Manager: Ensure the SOP is followed and updated as needed.

4. Equipment and Materials:

Soxhlet Apparatus (including extractor body, condenser, siphon tube, thimble, and boiling flask)

Heat source (e.g., heating mantle or water bath)

Solvent for extraction

Sample to be extracted

Personal Protective Equipment (PPE): Lab coat, gloves, safety goggles.

- Procedure:

Pre-Operation:

Ensure all glassware and components of the Soxhlet apparatus are clean and dry.

Check for any cracks or defects in the glassware. Do not use if any issues are found.

Assemble the Soxhlet apparatus securely using appropriate clamps and stands. Ensure the extractor body, condenser, and boiling flask are properly connected and sealed. Wear appropriate PPE before starting the procedure.

Fig: Soxhlet Apparatus

- Future Scope of present study :

The future scope for this study involves potential advancements in SOP handling and implementation, including:

• Automation and Digital SOPs: As laboratories adopt automated systems, digital SOPs integrated with laboratory information management systems (LIMS) could enhance SOP accessibility, compliance, and documentation.

• Enhanced Quality Control: SOP improvements and adherence will lead to more reliable quality control practices, resulting in better product consistency and consumer safety.

• Sustainable Practices: SOPs could incorporate sustainability principles, helping reduce wastage and environmental impact in cosmetic formulation processes.

• Training Standardization: Continued development and refinement of SOPs can lead to standardized training programs that prepare technicians and scientists more effectively for the industry’s evolving demands.

CONCLUSION:

The study of SOPs for handling instruments in cosmetic formulation and evaluation highlights their critical role in ensuring product quality, safety, and regulatory compliance. SOPs not only provide clear guidance for safe and effective instrument use but also serve as essential training resources for new personnel. However, for SOPs to remain effective, they must be regularly updated to reflect technological advancements and incorporate feedback from laboratory personnel. Future innovations, such as digital SOPs and sustainable practices, promise to enhance the efficiency, accuracy, and environmental responsibility of cosmetic Laboratories.

REFERENCES

- Mrs. A. S. Gudigenavar (25 Feb 2023) At BLDEA’S Shri Sanganbasava Mahaswamiji College of Pharmacy and Research Centre. The SOP of Brookfield Viscometer At Pharaceutics Laboratory, Vijayapur (page no: 1-3).

- The SOP of Microscope, Weighing Balance, PH Meter, UV-Visible Spectroscopy, Homogenizer and The Soxhlet Apparatus. from P. R. Patil Institute of Pharmacy, Talegaon (S.P.)

Dnyaneshwari Wankhade *

Dnyaneshwari Wankhade *

Hritika Bayaskar

Hritika Bayaskar

Janhavi keche

Janhavi keche

Kalyani Ranotkar

Kalyani Ranotkar

Kunal Takarkhade

Kunal Takarkhade

10.5281/zenodo.14534444

10.5281/zenodo.14534444