Abstract

At present, nanotechnology is widely utilized in drug delivery, facilitating both passive and active targeting through various administration routes. Solid lipid nanoparticles (SLNs) and nanostructured lipid carriers (NLCs) are the two primary types of lipid-based nanoparticles. Muller developed the NLCs in 1999-2000. NLCs come in three different forms: Imperfect, Amorphous and Multiple. Compared to SLNs, NLCs have a greater drug loading efficiency because their partially crystalline lipid system is created by blending liquid and solid lipids. Various excipients are used in formulating NLCs are commonly used liquid lipids and solid lipids, emulsifying agent, counter ions and surfactant for preparation of NLCs. For thermostable and thermos sensitive medication the high shear homogenization and micro emulsion like various methods for fabrication of NLCs have been described in this review. Evaluation of NLCs includes particle size determination, zeta potential, entrapment efficiency test, NLCs morphology, polydispersity index, stability test, structural analysis. NLCs have numerous pharmaceutical applications like inhalational, parenteral, topical, oral, ocular, brain and other.

Keywords

Targeted drug delivery, Controlled release, Nanostructured lipid carriers, Solid – Liquid lipid

Introduction

Currently, nanotechnology is extensively used in drug delivery, allowing for both passive and active targeting through different administration routes. Solid lipid nanoparticles (SLNs) and nanostructured lipid carriers (NLCs) are two main kinds of lipid-based nanoparticles. SLNs were created to address drawbacks of other carriers like emulsions, liposomes, and polymeric nanoparticles. They offer advantages such as a favourable release profile and targeted drug delivery, along with excellent physical stability.

In the next generation of lipid nanoparticles, NLCs are modified SLNs that enhance stability and loading capacity. Nanostructured lipid carriers (NLCs) are a newer type of lipid nanoparticles designed to address the issues of the first generation, known as SLNs. NLCs have become a promising carrier system for delivering medicines through methods like oral, injection, eye, lung, skin, and through the skin. NLCs are a combination of solid and liquid lipids, forming a less ordered lipid core. [1, 3]

History –

Muller developed the NLC carrier in 1999/2000. It took 5 years to launch the first two products, Nanorepair Q10 cream and Nanorepair Q10 serum, in Munich/Germany in 2005. The third product, Nanolipid CRL Restore, was launched within half a year. This makes NLC one of the nanocarriers with the shortest time from invention to market introduction. In 12 years, more than thirty products are now available commercially. [2]

Advantages and disadvantages of Nanostructured Lipid Carriers – [3]

Types of NLCs:

In simple terms, there are three types of Nanostructure Lipid Carriers (NLCs) based on how they're made and what lipids (fats) are used in their structure. The way these tiny carriers are put together and the ingredients used determine these categories. [4]

1. Imperfect type

2. Amorphous type

3. Multiple type

Imperfect type:

In simpler terms, this type of Nanostructure Lipid Carriers (NLCs) is made by using different types of fats with varying characteristics, like different lengths and levels of saturation in their carbon chains. Mixing these diverse fats creates a structure where the arrangement is not perfect, making it a bit disordered. This disorder allows the carrier to hold more medication, and it's less likely to expel the drug during storage compared to using just one type of fat.

Amorphous type:

In simpler terms, this type of Nanostructure Lipid Carriers (NLCs) creates a structure without a specific pattern, which helps to carry a lot of medication. They achieve this by making the lipid structure solid but not in an organized way, creating what is called an amorphous matrix. Using specific ingredients like medium chain Triglycerides, Hydroxyoctacosanylhydroxystearate, or Isopropylmyristate with a solid lipid can achieve this. Techniques like Nuclear Magnetic Resonance (NMR) and differential scanning calorimetry are used to confirm the solid state of the lipids and their transition temperatures, respectively.

Multiple type:

In simpler terms, this type of Nanostructure Lipid Carriers (NLCs) has a solid lipid structure that contains tiny droplets of liquid oil where the medication dissolves really well. This setup increases the amount of medication that can be held. Moreover, it allows for controlled release of the drug and minimizes the chances of drug leakage (which is good for stability), because the small oil droplets are surrounded and held in place by the solid lipid structure.

Figure 1 Importance of NLCs

Excipients used in formulating NLCs –

Figure 2 Excipients use in formulation of NLCs

Commonly used liquid lipids and solid lipids for preparation of NLCs: [4]

Emulsifying Agent

Poloxomer 407, Tween 20, Twee 40, Tween 80, Polyvinyl alcohol, Trehalose, Sodium deoxycholate, Sodium glycocholate, Sodium oleate, Polyglycerol methyl glucose distearate, Egg lecithin, Soya lecithin, Phosphatidylcholines, Phosphatidylethanolamines, Miranol ultra 32.

Counter-ions:

Sodium hexadecyl phosphate, Monodecyl phosphate, Mono hexadecyl phosphate, Mono octyl phosphate, Dextran sulphate sodium salt, Hydrolysed and Polymerized epoxidised soybean oil.

Surfactant:

The choice of surfactant significantly impacts the quality and efficacy of nanoparticle-based liquid crystallization (NLC), affecting toxicity, stability, and crystallinity. Surfactant systems also affect drug dissolution and permeability. Surfactants are chosen based on route of administration, hydrophilic-lipophilic balance (HLB) value, particle size, and lipid modification. Surface active agents (emulsifiers) help reduce tension between lipid and aqueous phases, ensuring stability. The required HLB (rHLB) is crucial for selecting the right type and amount of surfactant for NLC formulation, ensuring a stable nano system and small particle size. [3]

Method of preparation for NLCs:

Figure 3 Method of preparation of NLCs

- High Shear Homogenization -

Certainly, based on the information provided, it seems like the process involves two different approaches depending on the thermal stability of the medications: hot, high-a homogenization (HPH) for thermostable medications and cold HPH for thermosensitive ones. The following chart represents the key steps involved in the process: [5]

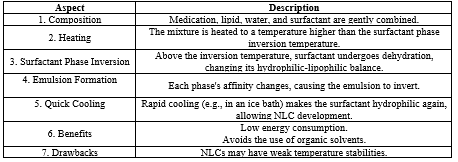

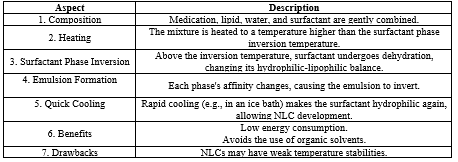

Microemulsion –

The described process involves creating Nanostructured Lipid Carriers (NLCs) through emulsification. Here is a summary of the key steps in a chart format: [5]

This chart outlines the sequential steps involved in the creation of NLCs using the described emulsification process, along with key characteristics of the approach.

- The Solvent Injection Technique –

Here's a chart summarizing the key aspects of the "solvent injection method" for the quick production of nanoparticles: [5]

Here's a chart summarizing the key steps and characteristics of the procedure described for the production of Nanostructured Lipid Carriers (NLCs): [5]

This chart provides a succinct summary of the key steps, benefits, drawbacks, and considerations related to the described procedure for Nanostructured Lipid Carrier (NLC) production.

- Solvent Emulsification-Evaporation Method -

Here's a chart summarizing the key points regarding the solvent emulsification-evaporation method for the preparation of Solid Lipid Nanoparticles (SLNs) and Nanostructure Lipid Carriers (NLCs): [6]

This chart provides a concise overview of the key steps, examples, benefits, drawbacks, and safety considerations associated with the solvent emulsification-evaporation method for SLNs and NLCs.

- Membrane Contactor Technique –

Certainly, here's a chart summarizing the key information about the membrane contactor method for lipid nanocarrier preparation: [6]

This chart provides a concise overview of the key aspects of the membrane contactor method for lipid nanocarrier preparation, including the method type, operation, droplet formation, advantages, and key process parameters influencing particle.

- Emulsification Solvent Diffusion Technique –

Here's a chart summarizing the key information about the solubilization of solid pigments and the production of lipid nanoparticles using partially water-soluble solvents: [7

- Supercritical Fluid Technique [SFT] -

Here's a chart summarizing the key steps and aspects of the method for preparing lipid nanoparticles from emulsions using Supercritical Fluid (SCF) technology, also known as "supercritical fluid extraction of emulsion": [7]

- Double Emulsion Technique –

Here's a chart summarizing the key steps and characteristics of the double emulsion method for the synthesis of Solid Lipid Nanoparticles (SLNs) and Nanostructured Lipid Carriers (NLCs): [7]

This chart provides a concise overview of the key steps and advantages of the double emulsion method for synthesizing Solid Lipid Nanoparticles (SLNs) and Nanostructured Lipid Carriers (NLCs), particularly when dealing with hydrophilic peptides and active medicinal components. Mechanism of particle formation is Lipid crystallization owing to solidification of emulsion.

Evaluation of Nanostructured Lipid Carriers (NLC)

Figure 5 Evaluation of NLCs

Particle size refers to the measure of subdivision of a solid material. It's an essential characteristic that affects many aspects of a product's quality and performance. This measurement is especially important in making various products, including pharmaceuticals. The stability of NLCs is greatly influenced by the particle size and the range of size distribution. Smaller particles with a narrow size distribution tend to be more stable, exhibiting a reduced likelihood of aggregation and physical instability during storage. Several factors affect particle size, including the type and concentration of surfactant, the manufacturing method, and the concentration and ratio of liquid lipids to solid lipids. The size of the particles affects their surface area and hence their solubility and biocompatibility as well as the rate of drug release. The formulation parameters, including the amounts and types of lipids, surfactants, and added drug, play a crucial role in determining the particle size and distribution of NLCs. Diameter of NLCs generally ranges from 10 to 1000 nm. [9, 10]

Zeta Potential –

It is the measure of the electrostatic repulsion or attraction between particles. The surface charge of Nanostructured Lipid Carriers (NLCs) is determined using zeta potential (ZP). Electrophoretic light scattering (ELS) measures the zeta potential of NLCs. The stability of the colloidal dispersion is indicated by the zeta potential. Higher the electrostatic repulsion between the particles the greater is the stability. If the ZP value is above +20 Mv or below -20 Mv, it indicates that the nanoparticles dispersion has good physical stability. [10, 11]

Entrapment Efficiency Test –

It is used to estimate the efficacy of a nanocarrier to retain the drug or active ingredient, to ensure delivery of an adequate amount of the component to the targeted site. Entrapment efficiency defines the ratio between the weight of entrapped drug and the total weight of drug added to the dispersion. [3, 9]

Actual drug content in nanoparticle

EE (%) = ------------------------------------------------ X 100

Total drug used in formulation

NLCs Morphology –

Scanning Electron Microscopy (SEM) -

It is used to visualize NLCs although it provides surface morphology information. The SEM is an instrument that produces a largely magnified image by using electrons instead of light to form an image. A beam of electrons is produced at the top of the microscope by an electron gun. The electron beam follows a vertical path through the microscope, which is held within a vacuum. [11, 12, 13]

Transmission Electron Microscopy (TEM) -

It gives high-resolution imaging of NLCs, and provide information about morphology, size, shape of particles. Transmission Electron Microscopy (TEM) is a useful method not just for fully understanding the physical and chemical properties of newly created nanoparticles but also for investigating how nanocomposites impact biological systems.

Atomic Force Microscopy (AFM) -

It is an uncomplicated and non-instructive method that can be used as a primary tool to both measure and alter the shape and size of lipid nanoparticles. Images were made using a special microscope i.e. Atomic Force Microscopy that measures how things interact. These experiments happened in the air at room temperature (25°C), with a method where a small amount of the final mixture was put on a small flat surface. After the liquid dried, the microscope was used again at room temperature. [3, 14]

Polydispersity Index –

The polydispersity index indicates the uniformity of particle sizes within the sample population, also known as the heterogeneity index. The polydispersity index (PDI) measured from Dynamic Light Scattering Instrument (DLS). This index is dimensionless. [15, 16]

PDI < 0>

PDI > 0.7 indicates a very broad particle size distribution in the sample.

Mw

Polydispersity index =

Mn

Where,

Mw = Weight average

Mn = Number average molecular weight

Stability Test –

The encapsulation of chemotherapeutic agents in lipid-based NPs improves their chemical and physical stability. Several factors, including storage temperature and pH, can influence the stability of drug-loaded Nanostructured Lipid Carriers (NLCs). A stability test was performed using real-time conditions at room temperature (25 ± 2 °C). [17]

Techniques to enhance stability of NLCs -

Lyophilization -

This is mostly used to prevent Ostwald ripening and to avoid the hydrolysis of moisture-sensitive drugs. If lyophilization is done without using a cryoprotectant, it can cause the aggregation of the lipid particles.

Commonly used cryoprotectant – Sorbitol, Mannitol, Glucose, Lactose, Sucrose, Mannose.

Spray Drying –

It is another option instead of lyophilization, and it's also less expensive. Lipid nanoparticles are made more stable in terms of their physical and chemical properties through a process called spray-drying. Before performing the spray drying of NLCs, it's important to ensure that the melting point of lipids is higher than the boiling point of the liquid used for spraying. This helps prevent the degradation of the lipids.

Addition of Poloxomer –

Poloxomer or Pluronics are a class of water-soluble nonionic triblock copolymers formed by polar (poly ethylene oxide) and non-polar (poly propylene oxide) blocks. which confer amphiphilic and surface active properties to the polymers. Various grades of poloxamers are employed as stabilizing agents. These are commonly used to improve the stability of gel nanoparticles.

Addition of PEG (Polyethylene glycol) –

Nanoparticles are coated with the substance like Polyethylene glycol.

It gives benefits like –

- Improves dispersibility of colloid.

- Decreases the alteration of lipids and growth of NLCs.

- It enhances blood circulation time.

- Helps with targeted drug delivery by changing the interactions of colloids with the mucosal membrane.

- Provides strong physical stability.

Spectral Analysis –

Figure 6 Spectral Analysis

Differential Scanning Calorimetry (DSC) –

Differential Scanning Calorimetry can figure out how NLC (Nanostructured Lipid Carrier) components behave when it comes to heat, like when lipids melt or interact with drugs. The substance was put into an aluminum container after weighing it at 2-8 milligrams. The temperature of the container was then increased at a rate of 10°C per minute until it reached a temperature between 30 and 300 °C. [9, 11]

X – Ray Diffraction Analysis (XRD) –

X-ray Diffraction assists in understanding the organized structure of lipid components and detecting any alterations in the crystalline form of drugs within Nanostructured Lipid Carriers (NLCs). [11]

Fourier Transform Infrared Spectroscopy (FTIR) –

FTIR spectroscopy is used to analyses chemical bonds and functional groups in NLC components and assess drug-lipid interactions. The samples were put into the sample holder on the device, pressed using a hydraulic press, and then scanned at a wave number of 400-4000 cm-1. [11]

Nuclear Magnetic Resonance (NMR) –

NMR (Nuclear Magnetic Resonance) spectroscopy can be applied to examine the interactions between drugs and lipids, as well as evaluate how drug molecules are distributed within the lipid structure. [11]

Applications -

Figure 7 Applications of NLCs

Inhalational –

Using inhaled drugs could be a promising approach to treat various lung-related conditions. Nanostructured Lipid Carriers (NLC) have been created and have several benefits. For instance, they can be used to deliver drugs to the lower respiratory tract. By reducing the particle size to below 500nm, there is an enhanced deposition in all lung regions because of increased diffusional mobility. A longer residence time in the lung is achieved due to the bioadhesive properties of NLC, attributed to their small particle size and lipophilic character. [18]

Parenteral –

Improved bioavailability, targeting, and enhanced cytotoxicity were achieved through the administration of Nanostructured Lipid Carriers (NLC) via the parenteral route. NLC is seen as a substitute for liposomes and emulsions because it comes with improved features. These include easy manufacturing, the ability to load a lot of drug, greater flexibility in controlling how the drug is released. This makes it suitable for delivering drugs through the veins with passive targeting ability and easy removal. [18, 19]

Topical –

Nanostructured Lipid Carriers (NLCs) can increase the apparent solubility of enclosed drugs. This helps in creating a high concentration gradient on the skin, making it easier for the drug to pass through. The nano-sized particles stick closely to the skin surface and release the drugs in a controlled way. Advantage of NLCs including the inclusion of biologically active and biodegradable lipids. These lipids are less harmful, offering features like adhesiveness, skin hydration, lubrication, smoothness, emollience, improved penetration into the skin, and modified drug release. [19]

Oral –

NLCs have been shown to be advantageous for giving poorly water-soluble drugs with low bioavailability through the mouth. In oral forms, Nanostructured Lipid Carriers (NLC) offer advantages such as higher drug loading, better drug inclusion, ease of use for patients, high concentration of particles, and a consistency similar to cream. Nanostructured Lipid Carriers (NLC) are a promising method for delivering drugs that are fat-soluble, have low bioavailability, and are particularly suitable for treating gastrointestinal diseases such as inflammatory bowel diseases. [4, 19, 20]

Ocular –

Delivering drugs to the eyes is challenging because of the unique physical and anatomical features of the eyes, along with various restrictions that need to be overcome to reach specific eye tissues. To overcome these challenges and improve the availability of drugs in eye tissues, NLCs were employed as an innovative method for drug delivery. NLCs provide various benefits such as –

- Enhance ocular bioavailability of drugs.

- Prolong residence time of the encapsulated drugs.

- Transcorneal drug delivery system. [4, 20]

Brain –

The significant benefits of this method of administration include bypassing the initial metabolism by the liver and achieving a quick onset of action. Nanostructured Lipid Carriers (NLC), from this generation are seen as a key approach for drug delivery without altering the drug molecule. This is due to their quick absorption by the brain, compatibility with the body, and ability to break down naturally. Colloidal drug delivery systems, such as Solid Lipid Nanoparticles (SLNs) and Nanostructured Lipid Carriers (NLCs), offer the advantage of prolonging the time drugs stay in the blood vessels of the brain. They also create a gradient that helps drugs move from the blood to the brain tissues. Additionally, they widen tight junctions to facilitate entry through the blood-brain barrier (BBB) and promote the transcytosis of drug-loaded Lipid Nanoparticles (LNPs) through the endothelium layer, further increasing the drug's retention time in the brain capillaries. [4, 19]

Other –

NLCs are not only beneficial for treating normal body functioning but also are applicable for various purposes. Some are as follows – [19]

- Cosmetics

- Chemotherapy

- Nutraceuticals

- In food industry

- Gene therapy.

CONCLUSION –

The application of NLCs is extensively used in drug delivery, allowing for both passive and active targeting through different administration routes. Nanotechnology, either SLN or NLC is an advantage. Following an analysis of the studies detailed in this review, we conclude NLCs are a blend of liquid and solid lipids. Consequently, the structural imperfections in the NLCs are increased, leading to improved drug loading and integration efficiency. The selection of excipients specifically solid lipids, liquid lipids, surfactants, emulsifying agents, and counter ions appears to play a significant role in the interaction mechanisms of nanocarrier. Evaluation are done for confirming a drug’s identity and assessing its quality and purity. They offer advantages such as favorable release profile and targeted drug delivery, along with excellent physical stability. NLCs have emerged as a promising system for drug delivery across various routes, including oral, injectable, ocular, pulmonary and transdermal administration.

REFERENCES

- Md A., Md S., Kaur S., Abbot S., Dang S., Jived A; Nanostructured lipid carriers system: Recent advances In drug delivery; Journal of Drug Targeting; 20; 29 Aug 2012; 813; http://dx.doi.org/10.3109/1061186X.2012.716845 .

- Naseri N.; Valizadeh H.; Milani P.; Solid Lipid Nanoparticles and Nanostructured Lipid Carriers: Structure, Preparation and Application; Advanced Pharmaceutical Bulletin; 3; 2015 Sep 19; 305, 306; http://dx.doi.org/10.15171/apb.2015.043.

- Chauhan I., Mohd Y., Verma M., Singh A.; Nanostructured Lipid Carriers: A Groundbreaking Approach for Transdermal Drug Delivery; Advanced Pharmaceutical Bulletin; 10; 2020 Feb 18; 150,151; http://dx.doi.org/10.34172/apb.2020.021.

- Mohammed E., Mohammad M.; Nanostructured lipid carriers (NLCs) as drug delivery platform: Advances In formulation and delivery strategies; Saudi Pharmaceutical Journal; 29; 9; 15 July 2021; 2,3,5; https://doi.org/10.1016/j.jsps.2021.07.015.

- Gomaa. E., Fathi.H.,Eissa.N., Elsabahy. M. ;Methods for preparation of nanostructured lipid carriers;Methods(Elsevier); 199,March 2022:2,3.; https://doi.org/3-810.1016/j.ymeth.2021.05.003; PMID: 33992771

- Duong.V. ,Nguyen.T.,Maeng.H.;Preparation of Solid Lipid Nanoparticles and Nanostructured Lipid Carriers for Drug Delivery and the Effects of Preparation Parameters of Solvent Injection Method; Molecules 2020,25,4781,5-7;https://doi.org/10.3390/molecules25204781

- Ganesana.P., Damodharan Narayanasamya.D.;Lipid nanoparticles: Different preparation techniques, characterization, hurdles, and strategies for the production of solid lipid nanoparticles and nanostructured lipid carriers for oral drug delivery; Sustainable Chemistry and Pharmacy (Elsevier); 25 July 2017;50,51; http://dx.doi.org/10.1016/j.scp.2017.07.002

- Chauhan.I., Yasir. M., Verma.M., Singh. A.;Nanostructured Lipid Carriers: A Groundbreaking Approach for Transdermal Drug Delivery.;Adv Pharm Bull.;10,2.;June 2020.;https://doi.org/10.34172/apb.2020.021.;PMID: 32373485.

- Suyuti.A.,Hendradi.E.,Purwanti.T.;Physicochemical Characteristics, Entrapment Efficiency, and Stability of Nanostructured Lipid Carriers Loaded Coenzyme Q10 with Different Lipid Ratios;Journal of Research in Pharmacy; 10 January 2023;1136 ,1137,1138,1139,1140;https://doi.org/10.12991/jrp.2019.00

- Haider, M.; Abdin, S.M.; Kamal, L.; Orive, G.; Nanostructured Lipid Carriers for Delivery of Chemotherapeutics: A Review;12;2020;288; https://doi.org/10.3390/pharmaceutics12030288

- Mahor.A.,Singh.P.,Gupta.R., Bhardwaj.P.,Rathore.P., Kishore.A., Goyal.R., Sharma.N., Verma.j., Rosenholm .j.,Bansal.k.;Nanostructured Lipid Carriers for Improved Delivery of Therapeutics via the Oral Route, Journal of Nanotechnology,2023;9; https://doi.org/10.1155/2023/4687959

- https://www.nisenet.org/catalog/scientific-image-atomic-force-microscope-illustration

- https://www.purdue.edu/ehps/rem/laboratory/equipment safety/Research Equipment/sem.html

- https://www.ccber.ucsb.edu/ucsb-natural-history-collections-botanical-plant-anatomy/transmission-electron-microscope

- Apostolou .M., Assi.S,Fatokun.A.,Khan.I.;The Effects of Solid and Liquid Lipids on the Physicochemical Properties of Nanostructured Lipid Carriers;Journal of Pharmaceutical Sciences;110, 8,2021;2865;https://doi.org/10.1016/j.xphs.2021.04.012.

- Danaei.M., Dehghankhold M., Ataei.S., Davarani H.,Javanmard R., Dokhani.A., Khorasani.S., Mozafari.M. ;Impact of Particle Size and Polydispersity Index on the Clinical Applications of Lipidic Nanocarrier Systems; pharmaceutics;18 May 2018; https://doi.org/10.3390/pharmaceutics10020057

- Garg,.J.Pathania.K.,Sah .S., Pawar.S.;Nanostructured lipid carriers: a promising drug carrier for targeting brain tumours;Future Journal of Pharmaceutical Sciences (2022) 8:25;12,13;https://doi.org/10.1186/s43094-022-00414-8

- Iqbal.A., Shadab.Md., Sahni.J., Baboota.S., Dang .S., Ali.J.; Nanostructured lipid carriers system: Recent advances in drug delivery; Journal of Drug Targeting; 2012; 20:10, 813-830;11, ; http://dx.doi.org/10.3109/1061186X.2012.716845

- Jaiswal.P., Gidwani.B.,Vyas.A.;Nanostructured lipid carriers and their current application in targeted drug delivery; Nanomedicine, and Biotechnology, (informa healthcare); 2014; 8,10,11,12; http://dx.doi.org/10.3109/21691401.2014.909822

- Beloqui.A., Maria Solinís.M.,Rodríguezz-Gascón.A., Almeida.A.,Veronique Préat.V.; Nanostructured Lipid Carriers: promising drug delivery systems for future clinics; Nanomedicine: Nanotechnology, Biology, and Medicine (2015);13,20; https://doi.org/10.1016/j.nano.2015.09.004

Vinayak Kachru Mhaismale.*

Vinayak Kachru Mhaismale.*

Dhanshri Baburao Panchal

Dhanshri Baburao Panchal

Pande Prajakta Rajendra

Pande Prajakta Rajendra

Pathade Gayatri Pramod

Pathade Gayatri Pramod

Patil Siddhesh Gopal

Patil Siddhesh Gopal

10.5281/zenodo.13501342

10.5281/zenodo.13501342