Abstract

This review focus on the role of polymers used in pharmaceutical drug delivery of therapeutic agents. The polymers are used as carriers for delivery of drug at target site. Biodegradable polymers are widely used in delivery of drugs at specific site of the body because they can be degraded at constant rate of drug release. Natural polymers are also used for drug delivery at predetermined rates. The release mechanism of the drug from these polymers is by Degradation, Diffusion and Swelling. For controlled drug delivery of the therapeutic agents, they are used in pharmaceutical industry as binders, as film coating to mask the unpleasant taste, to enhance the drug stability and to modify the release characteristics of the drug. Polymers are being used extensively in drug delivery due to their surface and bulk properties. They are being used in drug formulations and in drug delivery devices. These drug delivery devices may be in the form of implants for controlled drug delivery. Polymers used in colloidal drug carrier systems, consisting of small particles, show great advantage in drug delivery systems because of optimized drug loading and releasing property. Polymeric nano particulate systems are available in wide variety and have established chemistry. Nontoxic, biodegradable and biocompatible polymers are available. Some nano particulate polymeric systems possess ability to cross blood brain barrier. They offer protection against chemical degradation. Smart polymers are responsive to atmospheric stimulus like change in temperature; pressure, pH etc. thus are extremely beneficial for targeted drug delivery. Some polymeric systems conjugated with antibodies/specific biomarkers help in detecting molecular targets specifically in cancers. Surface coating with thiolated PEG, Silica-PEG improves water solubility and photo stability. Surface modification of drug carriers e.g. attachment with PEG or dextran to the lipid bilayer increases their blood circulation time. Polymer drug conjugates such as Zoladex, Lupron Depot, On Caspar PEG intron are used in treatment of prostate cancer and lymphoblastic leukemia. Polymeric Drug Delivery systems are being utilized for controlled drug delivery assuring patient compliance.

Keywords

Novel, Polymer, Drug, System, Nano, Biodegraded

Introduction

Polymers are macromolecules having very large chains, contain a variety of functional groups, can be blended with other low- and high–molecular-weight materials, and can be tailored for any applications. Polymers are the backbone of pharmaceutical drug delivery systems. They have been found extensive applications in drug delivery because they offer unique properties which have not been attained by any other materials. Polymers have been used as a important tool to control the drug release rate from the formulations and they are also enhance used as stabilizer, taste-masking agent, and protective agent in oral drug delivery. Polymers can bind the particles of a solid dosage form and also change the flow properties of a liquid dosage form. 1Advances in polymers led to development of several novel drug delivery systems due to proper consideration of surface and bulk properties of polymers. Due to this reason, polymers have been widely used in developing new technologies by many researchers. These new technologies contribute to make medical treatment more efficient and side effects are also reduced. Polymer play an important role in the Drug delivery system in terms of materials to assist delivery, excipients, and technology which allow fast or slow release of drugs from the formulation.2

Classification of polymers:-

Based on source:-

- Natural:-

Chitosan, Alginate, Gelatin, Albumin, Collagen, Dextran

- Semi-Synthetic:-

Hydroxy Propyl Methyl Cellulose (HPMC), Methyl Cellulose (MC),

- Hydroxy Propyl Cellulose (HPC)

Synthetic:-

Polyethylene, Polylactic acid, Polypropylene, Polyglycolic acid, Polyhydroxy Butyrate

Type of Polymerization: -

Addition Polymer:-

Polyethylene, Polypropylene, Polyvinyl Chloride

Condensation Polymer: -

Polyurethane, Polyester

Degradability: -

Biodegradable:-

Polylactic acid, Polyglycolic acid, Polycaprolactone, Polyanhydrides

Non-Biodegradable: -

Polydimethyl Siloxane, Polyether Urethane, Ethyl Cellulose

Nature of Polymer Water Interaction:-

Hydrophobic Polymer:-

Ethyl Cellulose, Polydiethyl Siloxane Hydrophilic Polymer :- Cellulosic: MC, HPMC, HPC, HEC, NaCMC. Cellulosic: Sodium Alginate, Xanthun gum, chitosan Hydrogel Material :- Cross- linked Polyvinyl Alcohol, Polyethylene Oxide, Polyacrylamide3

Role of polymers in drug delivery:-

- Immediate release dosage forms Tablets:

Polymers including polyvinyl?pyrrolidone and hydroxypropyl methylcellulose (HPMC) find uses as binders that aid the formation of granules that improve the flow and compaction properties of tablet formulations prior to tableting.

Capsules:

Many of the polymeric excipients used to “bulk out” capsule fills are the same as those used in immediate release tablets. Gelatine has been used almost exclusively as a shell material for hard (two?piece) and soft (one?piece) capsules. HPMC has recently been developed and accepted as an alternative material for the manufacture of hard (two?piece) capsules.

- Modified?release dosage form

To achieve gastro retention mucoadhesive and low?density , polymers have been evaluated, with little success so far, for their ability to extend gastric residence time by bonding to the mucus lining of the stomach and floating on top of the gastric contents respectively.

- Extended release dosage forms

Extended and sustained release dosage forms prolong the time that systemic drug levels are within the therapeutic range and thus reduce the number of doses the patient must take to maintain a therapeutic effect thereby increasing compliance. The most commonly used water insoluble polymers for extended?release applications are the ammonium ethacrylate copolymers (Eudragit RS and RL), cellulose derivatives ethyl cellulose, and cellulose acetate, and polyvinyl derivative, polyvinyl acetate.

- Gastroprotective Dosage Forms

Gastroprotective dosage forms offer an alternative strategy for achieving extended release profile, in which the formulation will remain in the stomach for prolonged periods, releasing the drug in situ, which will then dissolve in the liquid contents and slowly pass into the small intestine.4

TYPES OF POLYMERS IN PHARMACEUTICAL DRUG DELIVERY:

Polymers as floating drug delivery system

Polymers are generally employed in floating drug delivery systems so as to target the delivery of drug to a specific region in the gastrointestinal tract i.e. stomach. Natural polymers which have been explored for their promising potential in stomach-specific drug delivery include chitosan, pectin, xanthan gum, guar gum, gellan gum, karaya gum, psyllium husk, starch, alginates etc.5

Polymers used in mucoadhesive drug delivery system

The new generation mucoadhesive polymers for buccal drug delivery with advantages such as an increase in the residence time of the polymer, penetration enhancement, site-specific adhesion, and enzymatic inhibition, site- specific mucoadhesive polymers will undoubtedly be utilized for the buccal delivery of a wide variety of therapeutic compounds. This class of polymers has enormous potential for the delivery of therapeutic macromolecules. Application of lectin and “lectinomimetics” appears to be the most promising area of current research efforts aimed at the safe and effective delivery of drugs via the buccal mucosa.6

Polymers used as Colon Targeted Drug Delivery

Polymer plays a very important role in the colon targeted drug delivery system. It protects the drug from degradation or release in the stomach and small intestine. It also ensures abrupt or controlled release of the drug in the proximal colon. For examples Wong et al. studied the dissolution of dexamethasone and budesonide from guar gum-based formulations and observed that the drug release in simulated colonic fluid was markedly increased at galactomannanase concentrations >0.01 mg/ml. A novel colon targeted tablet formulation using pectin as a carrier and diltiazem hydrochloride and indomethacin as model drugs has been developed. In vitro study showed that prepared dosage forms have limited drug release in stomach and small intestine and released maximum amount of drug in the colon. McLeod et al. synthesized glucocorticoid-dextran conjugates in which dexamethasone and methylprednisolone were attached to dextran using dicarboxylic acid linkers (succinate and glutarate). Dextran conjugates resisted hydrolysis in upper GI tract contents but were rapidly degraded in cecal and colonic contents where the bacterial count is high. Chitosan capsules were used for colonic delivery of an antiulcerative colitis drug. 5- Aminosalicylic acid (5-ASA) was used as model drug. A marked increase in the release of drug from chitosan capsule was observed in the presence of the rat cecal content.7

Polymers for Sustained Release

Polymer used in the sustain release system by preparing biodegradable microspheres containing a new potent osteogenic compound. In order to achieve the sustained release of 3ethyl-4-(4-methylisoxazol-5-yl)-5- (methylthio) thiophene- 2-carboxamide, a new potent osteogenic compound for the treatment of bone disorders, prepared a microspheres containing BFB0261 and newly synthesized three poly (d, l-lactic acid) (PLA), four poly (d, l-lactic acid–co-glycolic acid) (PLGA), and eight poly (d, l-lactic acid)-block-poly(ethylene glycol) (PLAPEG) biodegradable polymers or copolymers, and evaluated the release pattern of microspheres.8

Polymers in implantable drug delivery

Polymer micro-needles are of interest for implantable drug delivery due to their enhanced biocompatibility, and capability to conform to tissue without shattering during the insertion or tissue reconfiguration processes. These devices have been fabricated using several polymers including polydimethylsiloxane (PDMS) ;), polylactic and polyglycolic acid (PLGA), block copolymer hydrogels , SU-8 photoresist , and polyimide . Bernardo et al 2010 developed a device that incorporates the flexibility and biocompatibility of polymer microneedles while still offering the advantages of active fluidic delivery devices in simple microfluidic architecture. This device uses a similar electrochemical release and dose control mechanism as our previous work (Chung and Erickson) but is now integrated into a flexible system as opposed to its silicon predecessor.9

Polymeric micelles

Polymeric micelles (PMs) are developed in response to the immediate needs of high selectivity of drug carriers. Nowadays many life threatening diseases, such as cancer, current chemotherapy of which, still face a most serious problem of lack of selectivity of anticancer drugs toward proliferative cells, thus, resulting in the cytotoxic action of these drugs. PMs formed from an amphiphilic block copolymer are suitable for encapsulation of poorly watersoluble, hydrophobic anticancer drugs. Importantly, critical features of the PMs as drug carriers, including particle size, stability, loading capacity and release kinetics of drugs allow PMs to be targeted to the tumor site by a passive mechanism called the enhanced permeability and retention effect.10

Polymers in tissue engineering

A wide range of natural–origin polymers with special focus on proteins and polysaccharides might be potentially useful as carriers systems for active biomoleculesor as cell carriers with application in the tissue engineering field targeting several biological tissues.

Protein-based in the tissue engineering field are:-

- collagen,

- gelatin

- silk fibroin, fibrin (fibrinogen) and

- Other proteins such elastin or soybean are used.

Several polysaccharides based polymers used in tissue engineering are:-

- Chitosan

- Starch

- Alginate

- Chondroitin sulphate 11

Polymers used in micro and nanoparticles for targeted drug delivery

Micro- and nanospheres fabricated from a biodegradable polymer for drug delivery systems have become increasingly important owing to the fact that such systems enable controlled drug release at desired sites. A number of polymers have been investigated for formulating biodegradable nanoparticles, such as polylactide (PLA), polycaprolactone (PCL) and poly (lactide-co-glycolide) (PLGA). These are biocompatible and biodegradable polymers which have recently been the subject of extensive investigation. Polymeric nano carriers such as poly (DL-lactide-co-glycolide) have shown promising pharmacokinetics both at the whole- body and cellular levels (passive targeting). The active drug targeting is usually achieved by the chemical attachment onto a targeting component that strongly interacts with antigens (or receptors) displayed on the target tissue, leading to the preferential accumulation of the drug in the targeted organ, tissue, or cells .12

Polymer drug conjugate

Polymer–drug conjugates achieve tumour-specific targeting by the enhanced permeability and retention (EPR) effect these macromolecular prodrugs comprise a minimum of three components, : a natural or synthetic, water-soluble polymeric carrier (usually of 10 000–100 000 Da), a biodegradable polymer–drug linkage (often a peptidyl or ester linkage) and a bioactive antitumour agent. Phase I/II clinical trials involving N-(2- hydroxypropyl)methacrylamide (HPMA) copolymer- doxorubicin (PK1; FCE28068) showed a four- to fivefold reduction in anthracycline-related toxicity, and, despite cumulative doses up to 1680 mg/m2 (doxorubicin equivalent), no cardiotoxicity was observed.13

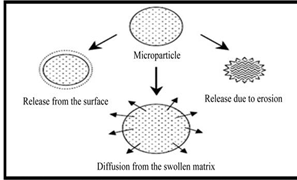

MECHANISM OF DRUG RELEASE FROM POLYMERS

Diffusion

Diffusion occurs when the drug passes from the polymer matrix into the external environment. As the release continues its rate normally decreases with this type of system since the active agent has a progressively longer distance to travel and therefore requires a longer diffusion time to release. In these systems, the combinations of polymer matrices and bioactive agents chosen must allow for the drug to diffuse through the pores or macromolecular structure of the polymer upon introduction of the delivery system into the biological environment without inducing any change in the polymer itself.14

Degradation

Biodegradable polymer degrades within the body as a result of natural biological processes, eliminating the need to remove a drug delivery system after release of the active agent has been completed. Most biodegradable polymers are designed to degrade as a result of hydrolysis of the polymer chains into biologically acceptable and progressively smaller compounds. For some degradable polymers, most notably the polyanhydrides and polyorthoesters, the degradation occurs only at the surface of the polymer, resulting in a release rate that is proportional to the surface area of the drug delivery system.15

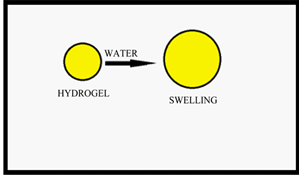

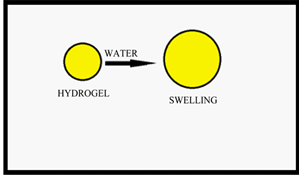

Swelling

They are initially dry and when placed in the body will absorb water or other body fluids and swell. The swelling increases the aqueous solvent content within the formulation as well as the polymer mesh size, enabling the drug to diffuse through the swollen network into the external environment.16

APPLICATIONS OF POLYMERS IN DRUG DELIVERY:-

Application in conventional dosage forms:-

- Tablets:-As binders to mask unpleasant taste for enteric coated tablets

- Liquids:- Viscosity enhancers For controlling the flow

- Semisolids:- In gel preparation

- In Ointments

- In transdermal Patches 17

Application in biomedical field:-

A. Water-Soluble Synthetic Polymers

- Poly (acrylic acid) Cosmetic, pharmaceuticals, immobilization of cationic drugs, base for Carbopol polymer.

- Poly (ethylene oxide) as Coagulant, flocculent, very high molecular-weight up to a few millions, swelling agent

- Poly (ethylene glycol) MW <10>

- <1000>1000) as plasticizer, base for suppositories

- Poly (vinyl pyrrolidone) aUsed to make betadine (iodine complex of PVP) with less toxicity than iodine, plasma replacement, tablet granulation.

- Poly (vinyl alcohol) Water-soluble packaging, tablet binder, tablet coating Polyacrylamide Gel electrophoresis to separate proteins based on their molecular weights, coagulant, absorbent.

- Poly (isopropyl acrylamide) and poly (cyclopropyl methacrylamide)

B. Cellulose-Based Polymers

- Ethyl cellulose Insoluble but dispersible in water, aqueous coating system for sustained release applications

- Carboxymethyl cellulose Super disintegrant, emulsion stabilizer

- Hydroxyethyl and hydroxypropyl celluloses

- Soluble in water and in alcohol, tablet coating

- Hydroxypropyl methyl cellulose Binder for tablet matrix and tablet coating, gelatin alternative as capsule material

- Cellulose acetate phthalate enteric coating

C. Hydrocolloids

- Alginic acid Oral and topical pharmaceutical products; thickening and suspending agent in a variety of pastes, creams, and gels, as well as a stabilizing agent for oil-in-water emulsions; binder and disintegrant

- Carrageenan: - Modified release, viscosifier

- Chitosan:- Cosmetics and controlled drug delivery applications, mucoadhesive dosage forms, rapid release dosage forms

- Hyaluronic acid Reduction of scar tissue, cosmetics

- Pectinic acid Drug delivery

D. Water-Insoluble Biodegradable Polymers

Lactide-co-glycolide polymers Microparticle– nanoparticle for protein delivery.

E. Starch-Based Polymers

Starch Glidant, a diluent in tablets and capsules, a disintegrant in tablets and capsules, a tablet binder Sodium starch glycolate Super disintegrant for tablets and capsules in oral delivery

F. Plastics and Rubbers

- Polyurethane Transdermal patch backing (soft, comfortable, moderate moisture transmission), blood pump, artificial heart, and vascular grafts, foam in biomedical and industrial products Silicones Pacifier, therapeutic devices, implants, medical grade adhesive for transdermal delivery

- Polycarbonate Case for biomedical and pharmaceutical products

- Polychloroprene Septum for injection, plungers for syringes, and valve components

- Polyisobutylene Pressure sensitive adhesives for transdermal delivery

- Polycyanoacrylate Biodegradable tissue adhesives in surgery, a drug carrier in nano- and microparticles

- Poly (vinyl acetate) Binder for chewing gum.

- Polystyrene Petri dishes and containers for cell culture Polypropylene Tight packaging, heat shrinkable films, containers

- Poly (vinyl chloride) Blood bag and tubing.

- Polyethylene Transdermal patch backing for drug in adhesive design, wrap, packaging, containers

- Poly (methyl methacrylate) hard contact Lenses Poly (hydroxyethyl methacrylate) Soft contact lenses 18

Applications of polymers for controlled drug delivery

- Reservoir Systems

- Ocusert System

- Matrix Systems

- Swelling Controlled Release Systems

- Biodegradable Systems

- Osmotically controlled Drug Delivery

- Introduction: Principles of Controlled Drug Delivery

- The Progestasert System

- Reservoir Designed Transdermal Patches

- Matrix Systems

- Stimulus Responsive Drug Release

- Ultrasound Responsive Drug Release

- Temperature Responsive Drug Release

- pH Responsive Drug Release

- Electric Current Responsive Drug Release

16. Polymer-Drug Conjugates 19

Future prospective of advanced drug delivery using polymers:-

Engineered Polymers for Advanced Drug Delivery

Smart polymers: - Modern drug delivery technology has been made possible by the advances in polymer science. Advancement in polymer science and engineering has developed new polymers for well- controlled delivery of therapeutic drugs. One of them will be the smart polymer (stimuli-sensitive polymer), which possesses active responsiveness to environmental signals and changes the physicochemical property as designed. Physical (temperature, ultrasound, light, electricity, mechanical stress), chemical (pH, ionic strength), and biological signals (enzymes, biomolecules) have been used as triggering stimuli.

LITERATURE REVIEW

Yong Kiel Sung & Sung Wan Kim et al 2020- Polymeric drug delivery systems have been achieved great development in the last two decades. Polymeric drug delivery has defined as a formulation or a device that enables the introduction of a therapeutic substance into the body.

Krishna kumar J Gandhi, Subhash V Dishman 2012-

The current review article focuses on polymers in pharmaceutical drug delivery of therapeutic agents. These dosage forms include tablets, patches, tapes, films, semisolids and powders. Polymers are the backbone of a pharmaceutical drug delivery system as they control the release of the drug from the device.

William B et al 2012-

Polymers have played an integral role in the advancement of drug delivery technology by providing controlled release of therapeutic agents in constant doses over long periods, cyclic dosage, and tunable release of both hydrophilic and hydrophobic drugs.

K J Gandhi 2011-

The current review article focuses on polymers in pharmaceutical drug delivery of therapeutic agents.

Apurva Srivastav 2010-

Polymers are being used extensively in drug delivery due to their surface and bulk properties. They are being used in drug formulations and in drug delivery devices.

METHOD AND METHODOLGY

RECENT DEVELOPMENTS IN USE OF POLYMERS FOR DRUG DELIVERY

SYSTEMS Oral drug delivery system has been in practice since many years as the most widely used root of administration among all the roots that have been employed for the systemic delivery of drug via various pharmaceutical products for different dosage forms. A large of both synthetic and natural has been studied for possible application in drug delivery system[6]. The most advantageous property of polymers is that they have been most widely used now a days. Two promising synthetic polymers which have been developed for biomedical applications are form polyvinyl pryolidone and polyethylene glycol acrylate based hydrogels. Both of them are biodegradable and forms copolymers with natural macromolecules. On the other side, natural polymers have the advantage of high biocompatibility and less immunogenicity. A special attention has been shown through the gelatin and collagen which are natural polymers[20]. Other natural polymers include chitosan, alginate, starch pectin, casein and cellulose derivatives. The composites of some of the above natural polymers with synthetic polymers give added advantages as carriers for drugs delivery by complimenting the properties of each other. Hybrid copolymers of collagen with biodegradable synthetic polymers polyethylene glycol 6000 and polyvinyl pyrolidone were developed for the controlled released of contraceptive some drugs have an optimum range within which maximum benefit is derived, and concentrations above or below this range can be toxic or produce no therapeutic belief it at all. On the other hand, the very slow progress in the efficacy of the treatment of severe disease, has suggested a growing need for a multidisciplinary approach to the delivery of therapeutics to targets in the tissues[19]. From this, new idea on controlling the pharmacokinetic, pharmacodynamics, non-specific toxicity, immunogenicity, biorecognition, and efficacy of drugs were generated. These new strategies, often called drug delivery system (DDS), are based on interdisciplinary approaches that combine pharmaceutics, polymer science, analytical chemistry, and molecular biology[25,26]. Polymers are used in the conventional dosage forms like binders for enteric coted tablets which mask the unpleasant taste, viscosity enhancers for controlling flow in liquids[12], gel preparation in case of semisolids and also used in preparation of transdermal patches[21,27]. Future trust Many researchers are working in this filed and have developed many modify copolymers with desirable functional groups, who visualize their use not only for controlled drug delivery systems, but also used for artificial organs lining, immunology testing, agents in drug targeting, chemical reactors and substrates for cell growth[17]. The most potential opportunities for these polymers in controlled drug delivery lie in the field of responsive delivery systems, it is expected that, in future even more than today, researches and doctors will have a wealth of products using biodegradable polymers that will help faster patient recovery and eliminate follow up surgeries[3]. Looking to present scenario and a wide range of research, total use of these biodegradable polymers in drug delivery applications is within reach in the near future.

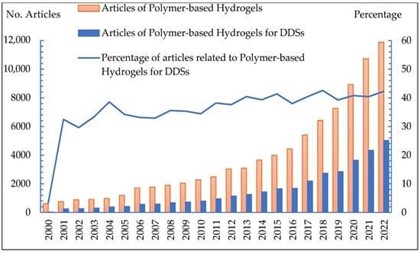

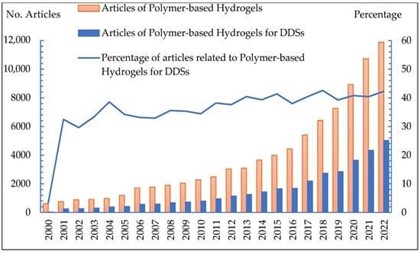

Figure 1. Increasing number of publications related to polymer-based hydrogels and polymer based hydrogels for drug delivery systems from 2000 to 2022.

Current and future research on polymer-based hydrogels applied in drug delivery systems is focused on advancing the field by addressing existing challenges and exploring innovative approaches. In the future, it is predicted that the key trends and areas of research in the polymerbased hydrogels applied for drug delivery systems will include the following:

- Advanced drug release strategies:

Researchers are developing novel drug release strategies that offer precise control over the release rate and duration of therapeutic agents. This includes the development of stimuli-responsive polymer-based hydrogels that can release drugs in response to specific triggers such as pH, temperature, enzymes, or light. Additionally, efforts are being made to incorporate drug delivery mechanisms such as sustained release, pulsatile release, and on-demand release into polymer-based hydrogel systems.

- Targeted and site-specific delivery:

Enhancing the targeting efficiency and specificity of drug delivery systems is a major focus. Researchers are exploring the incorporation of targeting ligands, such as antibodies, peptides, or aptamers, into polymer-based hydrogels to improve the delivery of drugs to specific cells, tissues, or organs. The use of external stimuli, such as magnetic fields or ultrasound, to guide the polymer-based hydrogel to the target site is also being investigated.

- Combination therapy:

Polymer-based hydrogels are being studied for their potential to deliver multiple therapeutic agents simultaneously, enabling combination therapy. This includes the co-delivery of drugs with different mechanisms of action or the incorporation of drugs and biological molecules, such as growth factors or gene therapies, within the polymer-based hydrogel matrix. Combination therapy can enhance therapeutic efficacy, reduce side effects, and overcome drug resistance.

- Bioactive polymer-based hydrogels:

Researchers are incorporating bioactive molecules, such as peptides or growth factors, into hydrogels to promote tissue regeneration and healing. These bioactive polymer-based hydrogels can provide a suitable microenvironment for cells, promote cell adhesion and proliferation, and support tissue integration. Such polymer-based hydrogels hold promise for applications in wound healing, tissue engineering, and regenerative medicine.

- Nanotechnology and nanoparticles:

Nanoparticles and nanotechnology are being integrated into polymer-based hydrogel systems to enhance drug loading, stability, and release. Nanoparticles, such as liposomes, polymeric nanoparticles, or inorganic nanoparticles, can be incorporated within the polymer-based hydrogel matrix or used as carriers to encapsulate drugs. These nanoparticles can provide controlled release profiles, protect drugs from degradation, and enable targeted delivery.

- 3D printing and additive manufacturing:

Advances in 3D printing and additive manufacturing techniques have opened new avenues for the fabrication of complex and customized hydrogel-based drug delivery systems. Researchers are exploring the use of 3D printing to create patient-specific implants, scaffolds, or drug-loaded structures with precise control over shape, architecture, and drug distribution.

- Smart polymer-based hydrogels and sensors:

The integration of smart polymerbased hydrogels with sensing capabilities is an emerging area of research. These hydrogels can detect and respond to specific biological or environmental cues, such as pH changes, enzyme activity, or the presence of specific biomarkers. By incorporating sensors into polymer-based hydrogels, the real-time monitoring of drug release, therapeutic efficacy, or disease progression can be achieved.

- Biodegradability and sustainability:

Researchers are focusing on developing biodegradable hydrogels that can degrade in a controlled manner, eliminating the need for surgical removal. The use of biocompatible and sustainable materials, such as natural polymers or biomimetic materials, is also gaining attention to reduce the environmental impact of hydrogel-based drug delivery systems. The future of research into polymer-based hydrogels for drug delivery systems lies in designing more sophisticated, targeted, and patient-specific approaches. The integration of advanced technologies, materials, and knowledge from various disciplines will continue to drive innovation in this field, leading to improved therapeutic outcomes and personalized medicine. Chemical engineers, pharmacologists and scientists are using polymers for developing controlled drug release systems and sustained release formulations [3] . Novel drug delivery systems include micelles, dendrimers, liposomes, polymeric nanoparticles, cell ghosts, microcapsules and lipoproteins. Recent advancements in polymer based encapsulations and controlled drug release systems help in regulating drug administration by preventing under or overdosing [2] . These advanced systems play a promising role in improving bioavailability, minimizing side effects and other types of inconveniences caused to the patients. Studies need to be performed in the areas of surface and bulk properties of polymers as these properties govern their utilization various applications. Role of polymers in drug delivery will grow steeply in future to handle various unsolved issues. These issues may include site specific drug delivery in subcellular organelles, harnessing chemical, physical and biological properties efficiently to optimize drug administrations. Nano composites have shown to penetrate deep blood brain barriers [2] . Through this paper we emphasize on the role of polymers in existing and novel drug delivery systems both as formulations and in devices, their advantages and limitations.

Advantages:

- Polymers used in colloidal drug carrier systems, consisting of small particles, show great advantage in drug delivery systems because of optimized drug loading and releasing property

- [1] .

- A polymer (natural or synthetic) is aggregated with a drug in controlled drug delivery and hence it gives a effective and controlled dose of dug avoiding overdose [1] .

- The degradable polymers are ruptured into biologically suitable molecules that are assimilated and discarded from the body through normal route.

- Reservoir based polymers is advantageous in various ways like it increase the solubility of incompetently soluble drugs and it lowers the antagonistic side effects of drugs [2] .

- Magneto-optical polymer coated and targeted nanoparticles are multimodal (optical and MRI detection) while Quantum Dots are only optically detectable.

- Some Quantum dots contain Cd which is known to be toxic to humans. Magneto/optical nanoparticles whether polymer coated or targeted are composed of iron oxides/polymers which are known to be safe, therefore have great future.

- Dextrans is the common polymer used for coating of iron oxide (plasma expander and affinity for iron) and are used for treatment of iron anaemias since 1960 and is still in operation. 8. In controlled release, some of the polymers like polyurethanes for elasticity, polysiloxanes for insulating ability are used for their intended non-biological physical properties.

- Current polymers like Poly 2-hydroxy ethyl methacrylate, polyvinyl alcohol, Polyethylene glycol are used because of their inert characteristics and also they are free of leachable impurities [3] .

- In Biodegradable polymers, the system is biocompatible and it will not show dose leaving behind at any time and the polymer will keep its properties until after exhaustion of the drug.

- In hydrogels like drug delivery systems, the properties of polymer materials like PEG,(the easy polymer used to design hydrogels), can be managed to enhance features like size of the pore, which is used to manage rate of diffusion of the conveyer drugs. PEGylation was considered to minister many diseases like hepatits B and C, neutropaenia connected with cancer chemotherapy (PEG-GCSF) 28 and various types of cancers [PEG] glutaminase merged with a glutamine anti-metabolite 6-diazo-5-oxo-norleucine (DON].

- Polymers span from their use as films or binders covering agents in tablets to flow managing agent in liquids or emulsions for improving drug security and to alter the delivering characteristics. Micelles due to its smaller size have a small circulation time in the body. Hence, it results in an advantage of entering in the tumour cells easily, because of the EPR effect.

- Large importance of polymers in drug delivery has been noticed because they give a distinctive property which so far is not achieved by any of the materials [4] .

- Polymers are preferable in the fact that they habitually show a pharmacokinetic profile as contrast to small-scale molecule drug with lengthy circulation time and they also have the ability for tissue targeting.

- Gold nanoparticles are easy to prepare, good capability of co existence, and their capacity to attach with other biomolecules without changing their properties.

- Biggest benefit of utilizing polymers in drug delivery is their control (manipulation) on their properties (e.g. linkers and molecular weight) to modify to the need of drug delivery systems.

Difficulties and challenges

- Difficult to scale the process up and production in high amounts is expensive as microspheres are batch operations inherently [9] .

- It is possible to reproduce the distribution of size of the microsphere particles but the result is not uniform generally and the standard deviation that we get is equal to half of the average size. This is quite common. The distribution of the size should be as narrow as possible since the rate at which the drug will be released as well as syringability depends on the size of the sphere directly.

- With the presence of organic solvents and aqueous-organic interfaces on drugs that are encapsulated leads to adverse effects like eliminating the bioactivity of microspheres.

- It is not an easy task to remove the organic solvents totally as mostly they are toxic and there should be a regulation on the concentration of residual solvents in the microsphere.

- A crucial limitation in the development of biodegradable polymer microspheres for controlled-release drug delivery applications is the difficulty of specifically designing systems that exhibit precisely controlled release rates.

- Core-shell microparticles are significantly more difficult to manufacture than solid microspheres.

- Handling and fabricating the microspehre’s architecture is not easy as its shell and core must be immiscible.

- Hydrogels have an ability to rapidly swell with water which may lead to faster release of the loaded drug than desired followed by the degradation of the polymer [10] . There is a period of release of hours to days for hydrophilic drugs that are delivered usinghydrogel systems and it is considered to be much lesser than hydrophobic polymers based delivery systems like microspheres or nanospheres.

- There is a probability of controllable drug administration through the electrical stimulation of conducting polymers. One of the examples of such a polymer is polyprrole (Ppy) [11] . But they are not used generally as they have limitations related to the choice of dopant and molecular weight of the delivered drug.

- A hindrance to oral administration of some classes of drugs, mainly peptides and proteins is caused due to hepatic first-pass metabolism [12] and degradation by enzymes within the gastrointestinal tract.

- There are limitations of the mucosal surface for drug delivery as well. The first limitation being the low flux associated with mucosal delivery and the second as well as a major limitation of the trans mucosal route of administration is at the site of absorption due to lack of dosage form retention.

- The conventional chemotherapeutic agents (using Nano scale polymers as carriers) that we are aware of work by destroying the cells that rapidly divide. This leads to the damage of normal healthy cells that divide rapidly such as cells in the macrophages, bone marrow, digestive tract, and hair follicles due to chemotherapy.

- There are some side effects in many chemotherapeutic agents that includes mucositis (lining of the digestive tract affected by inflammation), loss of hair (alopecia), myelosuppression (white blood cells production is reduced leading to immunosuppression),dysfunction of the organ, and even anemia or thrombocytopenia [13] . These side effects lead to some difficulties like they impose dose reduction, treatment delay, or the given therapy is not continuous.

- The cell division may be efficiently stopped near the center in solid tumor cells because of which chemotherapeutic agents become insensitive to chemotherapy.

- Most of the times chemotherapeutic agents cannot penetrate and reach the core of solid tumors because of which they fail to kill the cancerous cells.

- Most of the traditional chemotherapeutic agents often get excreted from the circulation being engulfed by macrophages and therefore they remain in the circulation for a very short time and cannot interact with the cancerous cells that lead to ineffectiveness of the chemotherapy.

- Collagen has a limitation that it causes immunogenic responses in some patients therefore is not fit for use. It has a variant, atelocollagen. Atelocollagen preparation involves removal of the telopeptide from collagen. It has also been used for decrease in the potential immunogenicity. Collagen also has a poor mechanical strength and it cannot easily develop reproducible release rates [14] .

- Gelatin is cross-linked with glutaraldehyde while preparing the drug delivery system. This binds to and inactivates some protein drugs.

RESULT AND DISCUSSION

Diffusion-controlled mechanism

The first of which is the diffusion-controlled mechanism. There can be two systems in which this can be realized: via the reservoir system or the non-erodible matrix system. The reservoir system can be in the form of capsules, microcapsules, hollow fibers, and membranes, whereby the drug is encapsulated within the polymer (such as silicone, ethylene-vinyl acetate, and hydrogels), and thus the polymer surrounds the drug. Diffusion through the polymer allows for steady and slow release of the drug over long periods. In contrast, the non-erodible matrix system, which also relies upon diffusion for drug release, has the drug dispersed in the polymer. However, this means that steady release is more difficult to achieve than the reservoir system. One advantage of the non-erodible matrix system over the reservoir system is its safety profile. With a sudden breakage or tear of the polymer system, less drug leakage would result as it is embedded in the polymer, lowering the chances of toxicity.

Chemically-controlled mechanism

In addition to the diffusion-controlled mechanisms, there are also chemically controlled mechanisms. This may involve chemical reactions that result in the gradual drug release via the complete dissolution of the polymer that encapsulates the drug, known as the bio-erodible matrix system. Another chemically controlled mechanism is the covalent polymer-drug conjugate, whereby drugs are bonded to a polymer backbone and rely on water or an enzyme to cleave the drugpolymer backbone bond for drug release.

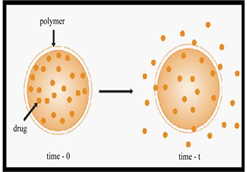

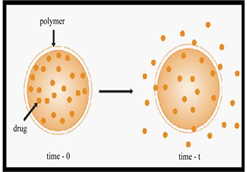

Solvent-controlled mechanism

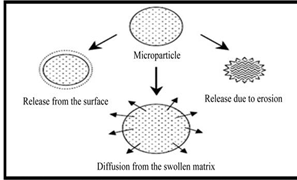

Furthermore, there is the solvent-controlled mechanism. One involves water diffusion into a hydrophilic polymeric system within an aqueous environment, such as body fluid. This induces the swelling of the polymer and, in turn, promotes the release of the drug, which is dissolved in the polymer. Known as swelling-controlled release, the drug release rate depends on the water diffusion rate and the polymer's chain relaxation rate. In addition, a system built around an osmotic pump has also demonstrated effectiveness in bringing about controlled release. The osmotic-controlled release system involves a carrier, such as a tablet, covered in a semi-permeable membrane with laser-drilled holes. The drug, dissolved in polymer, is released via the holes as water flowing through the semi-permeable membrane produces osmotic pressure, and thus, in essence, the active drug is pushed out [2]. Given the concentration gradient across the membrane remains constant, a zero-order controlled release is maintained. Polymers have become an integral part of drug delivery systems due to their improved pharmacokinetic properties. They have better circulation time than conventional small drug molecules thus target tissue more specifically. Tremendous use of polymers has been witnessed in the area of polymer therapeutics and Nano medicines. Polymers in reservoir based drug delivery systems have shown immense progress in the form of hydrogels and liposomes. Diffusion based drug delivery systems (as shown in Figure 1) and solvent activated drug delivery systems are the other areas being explored for utilizing the polymers . In diffusion based drug delivery systems drug is dissolved in a non-swell able system or a fully swollen matrix which do not decompose during their activation time. Solvent activated systems like hydrogels swell and release the drug when exposed to aqueous environment; this mechanism is depicted in Figure 2. They are hydrophilic in nature . Biocompatible polymers offer a safe passage for drug delivery due to their well engineered molecular architecture according to the transitions in the underlying mechanisms of the biological process. Biodegradable polymers break due to cleavage of covalent bonds between them and bio erodible polymers bring about erosion of the polymer due to dissolution of linking chains without bringing about any change in chemical structure of the molecule [2] . Various drug release mechanisms can be studied comparatively in Figure 3. Polymers serving as drug carrier should be water soluble, nontoxic and non-immunogenic. They work passively in minimizing drug degradation and improving circulation time. Another important issue is the safe excretion of the drug [1] . If the polymer is non- degradable it should be ensured that it is not accumulated within the body and if it is degradable the broken components should be such that they lie below renal threshold level, non toxic and should not produce any immune response [1] . Polymers mimicking biological systems respond to external stimulus such change in pH or temperature and as a result their properties such as solubility, hydrophobic/ hydrophilic balance, release of biomolecule (drug molecule) and conformation are altered [1] .

Various Polymers Used in Drug Delivery

PLGA

In past two decades poly lactic-co-glycolic acid (PLGA) has been among the most attractive polymeric candidates used to fabricate devices for drug delivery and tissue engineering applications. PLGA is biocompatible and

Figure 2. Diffusion based drug delivery system [6] .

Figure 3. Hydrogel based drug delivery system.

Figure 4. Various drug release mechanisms [5] . biodegradable, exhibits a wide range of erosion times, has tunable mechanical properties.

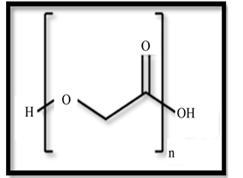

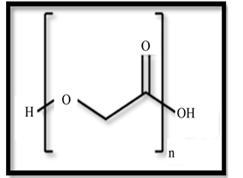

PGA(poly glycolic acid)

Polyglycolic acid (PGA) is a biodegradable, thermoplastic polymer and the simplest linear, aliphatic polyester. It can be prepared starting from glycolic acid by means of polycondensation or ring-opening polymerization. PGA has been known since 1954 as a tough fiber-forming polymer.

PGA(poly glycolic acid)

Poly-l-glutamic acid

Polyglutamic acid (PGA) is a polymer of the amino acid glutamic acid (GA). Gamma PGA is formed by bacterial fermentation.

Gamma PGA has a wide number of potential uses ranging from food and medicine to water treatment. It is widely being used as a drug delivery system in cancer treatment.

Poly-l-glutamic acid

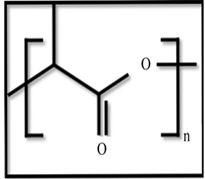

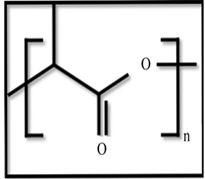

Polylactic acid

It is a biodegradable thermoplastic aliphatic polyester derived from renewable resources, such as co r n starch (in the United States and Canada), tapioca roots, chips or starch (mostly in Asia), or sugarcane (in the rest of the world).

Poly lactic acid

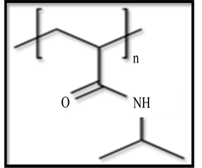

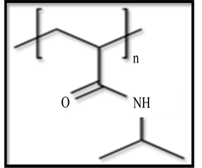

PNIPAAm [Poly(N-isopropylacrylamide)]

It is a temperature responsive polymer that was first synthesized in the 1950s.It can be synthesized from N-isopropylacrylamide which is commercially available. It is synthesized via free radical polymerization and is readily functionalized making it useful in a variety of applications.

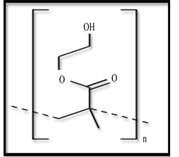

PNIPAAm [Poly(N-isopropylacrylamide)] pHEMA[Poly 2-hydroxyethyl methacrylate] It is a polymer that forms a hydrogel in water. Poly (hydroxyethyl methacrylate). It was invented by Drahoslav Lim and Otto Wichterle for biological use. Together they succeeded in preparing a cross-linking gel which absorbed up to 40% of water, exhibited suitable mechanical properties and was transparent. They patented this material in 1953.

pHEMA[Poly 2-hydroxyethyl methacrylate]

PPy [Polypyrrole]

It is a type of organic polymer formed by polymerization of pyrrole. Polypyrroles are conductin polymers, related members being polythiophene, polyaniline, and polyacetylene. The Nobel Prize in Chemistry was awarded in 2000 for work on conductive polymers including polypyrrole. The first examples of polypyrroles were reported in 1963 by Weiss and coworkers.

PPy [Polypyrrole]

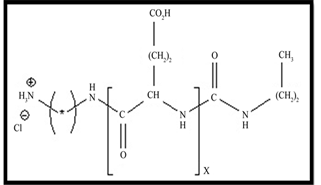

PAMAM [Poly (amidoamine)]

It is a class of dendrimer which is made of repetitively branched subunits of amide and amine functionality. PAMAM dendrimers, sometimes referred to by the trade name Starburst, have been extensively studied since their synthesis in 1985, and represent the most wellcharacterized dendrimer family as well as the first to be commercialized. Like other dendrimers, PAMAMs have a sphere-like shape overall, and are typified by an internal molecular architecture consisting of tree-like branching, with each outward “layer”, or generation, containing exponentially more branching points

PAMAM [Poly (amidoamine)]

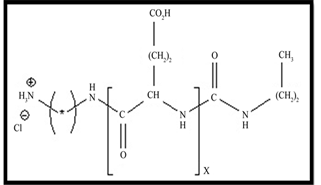

DEXTRAN

DEXTRAN

STRUCTURE:

Dextran is can be defined by Leuconostoc mesenteroides (lactic-acid bacteria with the help of which dextran is synthesized using sucrose) which contains a glucan which is (16)-linked and has side chains that are attached to the backbone of 3-positions of glucose units. The straight chain consists of ?-1,6 glycosidiclinkages between the molecules of glucose. The branching starts from ?-1,3 linkages [1] .

DISCOVERY HISTORY?

Allene Jeanes was a scientist at the USA's Northern Regional Research Lab in 1940. One day a company of soft drinks sent them one sample of their product which became thick and sticky. It was found out that this stickiness was due to the presence of a bacterium that converted the sugar present in the soda to dextran. This bacteria was assumed to have come from the dental plaque of one of the workers at the factory. The scientist then discovered that bacterium can be grown in the lab in a sugar solution which will make lots of dextran. This was then purified, dried and sent to korea which helped the soldiers to survive and helped them to heal.

2. Conventional Use of Polymers in Drug Delivery

Conventional drug delivery systems use doses of drugs in form of capsules, tablets which are formed by compression, coating and encapsulation of bioactive drug molecules [2] . Polymers play a versatile role in such conventional formulations; they serve as binding agents in capsules, film coating agents in tablets and viscosity enhancers in emulsions and suspensions. Some of the polymers given along with bioactive drug molecules include cellulose derivatives, poly (Nvinyl pyrrolidone) and poly (ethylene glycol) PEG.

NOTE:

Polymeric micelles have a core shell structure formed by spontaneous self-assembly of individual amphiphilic di/tri block co-polymers (shown in Figure 7). They have both hydrophilic and hydrophobic regions which is good for drugs with poor solubility. Core is formed by hydrophobic block polymer blocks (poly-(propene glycol), poly-(caprolactone) etc.) and shell is made up of hydroplilic polymer (PEG).

CONCLUSION

The use if novel polymers not only offers benefits but also can to be harmful because of the toxicity and other incompatibilities associate with them. Polymers possessing a unique strength in their application towards drug delivery application which enables the new advancement in the formulating new drug delivery systems which improves the therapy and treatment . Care should be taken to properly select polymers while designing a delivery system. The ultimate goal is to introduce cost effective ,biocompatible, multifunctional. less toxic polymers so that the delivery systems pass through the various phases of clinical trials and benefit the society . Among various types of polymer hydrogels polymer blends of natural and or synthetic polymer are used in the pharmaceutical formulations .In that controlled drug delivery systems having a advantages over conventional therapy fall into various categories such as diffusion – controlled chemically controlled, solvent activated and modulated release systems. On the whole, polymers are being extensively used in pharmaceutical industry due to their vast applications.

REFERENCES

- Aggarwal S, Goel A, Singla S, Drug Delivary: Special Emphasis Given On Bioderadable Polymers, Advances in Polymer Science and Technology: An International Journal, 2012, 2(1), 1-15

- Raizada A, Bandari1 A, Kumar B, Polymers in drug delivery : A Review International journal of pharma research and development (IJPRD),2010,vov-2,issue-8, 9-20

- Chandel P, Rajkumari, Kapoor A, Polymers – A Boon To Controlled Drug Delivery System, International research journal of pharmacy (IRJP) , 2013, 4(4), 28 – 34

- Gandhi KJ, Deshmane SV, Biyani KR, Polymers in Pharmaceutical Drug Delivery System: A Review, International Journal of Pharmaceutical Sciences Review and Research, 2012, 14(2), 10, 57?66

- Pahwa R, Bhagwan S, Kumar V, Kohli K, Role of Natural Polymers in the Development of Floating Drug Delivery Systems, Journal of Pharmacy Research (JPR), 2010, 3(6),1312-1318

- Sanghi DK , Borkar DS & Rakesh T , Asian Journal of Biochemical and Pharmaceutical Research, 2013,Issue 2(Vol. 3) , 169-178

- Rajpurohit H, Sharma P, Sharma S,Bhandari A , Indian J Pharm Sci. 2010 Nov-Dec; 72(6): 689–696.

- CG. Wilson, G. Mukherji, HK. Sha, “Modified-release Drug Delivery Technology”. In: Rathbone MJ, Had graft J, Roberts MS, Lane ME, editors. Biopolymers and Colonic Delivery. 2nd ed. 1. New York: Informa Healthcare; 2008, 295.

- Bernardo Cordovez, Aram J. Chung, Michael Mak, David Erickson, A novel polymer microneedle fabrication process for active fluidic delivery (2011) 10,785–791 Pua X, Liub J, Guoc Y, Yana X, Yanga H, Yuana Q, Study progression in polymeric micelles for the targeting delivery of poorly soluble anticancer agents to tumor, Asian Journal of Pharmaceutical Sciences (AJPS)2012, 7 (1), 1-17

- Malafaya PB , Silva GA , Reis RL ,Natural origin polymers as carriers and scaffolds for biomolecules and cell delivery in tissue engineering applications, Advanced Drug Delivery Reviews 59 (2007),207-233

- Stevanovi M, Uskokovi D ,Poly(Lactide- co- glycolide) based Micro And Nanoparticles for Controlled Drug Delivery Of Vitamins, Current Nanoscience, 2009,Vol.5, No. 1,115

- Duncan R, Vicent MJ, Greco F, and Nicholsan RI, Polymer– drug conjugates: towards a novel approach for the treatment of endrocine-related cancer, 2005, 12, S189-S199

- Poddar RK, Rakha P, Singh SK, Mishra DN, Bioadhesive Polymers as a Platform for Drug Delivery: Possibilities and Future Trends, Research J on Phamacetical Dosage Form and Technology, 2,1,2010, 40?54.

- Sharma K, Natural biodegradable polymers as matrices in transdermal drug delivery, Int. J. Drug Dev. & Res., April? June 3 (2): 2011, 85?103

- Satturwar, P.M.; Fulzele, S.V.; Dorle, A.K. Biodegradation and in vivo biocompatibility of rosin: a natural film?forming polymer. AAPS PharmSciTech. 4, 2003, 1?6.

- Pal DK, De T, Baral A , Polymers In Pharmacy: Their Versatile Applications, An International Journal of Advances in Pharmaceutical Sciences , volume 4 , Issue 1, 2013,54-65

- Review on Applications of Polymers in Pharmaceutical Formulations, Pharmatutor 18. URL - http://www.researchandmarkets.com/reports/224996/

Wasif Rao*

Wasif Rao*

Mohd Asad

Mohd Asad

Indu Saini

Indu Saini

Bishal Singh

Bishal Singh

10.5281/zenodo.13350424

10.5281/zenodo.13350424